Rollo de lámina de plástico GAG

Pet-sheet.com (Desu Technology) es uno de los mejores Rollo de lámina de plástico GAG Fabricante y fábrica en China. Contamos con tecnología y equipos avanzados, mucha experiencia en exportación y comercio internacional con clientes en más de 60 países. Suministro de muestras gratuitas, se aceptan OEM y ODM

| Nombre: | Rollo de lámina de plástico GAG |

| Fabricante: | Desu Tech(pet-sheet.com) |

| Proceso de producción: | coextrusión multicapa |

| Especificación: | Tamaño: Ancho 300-850mm (PP/PS) & 300-1400mm (PET); Espesor: 0.18-2mm; Embalaje: Máximo 150kg/rollo; Color: Primario/transparente/negro/blanco/colores personalizados |

| Principales aplicaciones: | Envasado en blíster/bandeja de tránsito/envasado de electrónica/envasado de ingredientes frescos |

| Pedido mínimo: | 1 ton (support free sampling) |

Conocimientos básicos de GAG

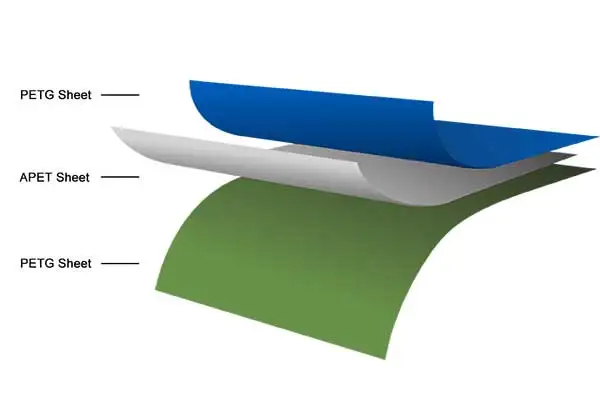

La lámina GAG es una lámina de PET compuesta de tres capas. La capa intermedia está hecha de APET y las capas superior e inferior están hechas de PETG. Las materias primas se coextruyen según la proporción adecuada. Es especialmente adecuado para cajas de embalaje que necesitan ser unidas mediante termosellado de alta frecuencia y pegamento.

Por qué elegir láminas de plástico GAG

La laminación por coextrusión multicapa es uno de los métodos más utilizados en la industria de materiales de embalaje para obtener materiales de embalaje con excelentes propiedades integrales. Combinando materiales con diferentes propiedades, se puede obtener un material compuesto con excelentes propiedades integrales. El material compuesto tipo GAG utiliza un proceso de coextrusión multicapa, lo que hace que el material compuesto tenga una excelente resistencia al impacto y rendimiento de termosellado del material PETG, mientras que el material base es material APET de precio relativamente bajo, lo que hace que el material tenga un mejor rendimiento de costos. . Se puede aplicar en zonas donde la APET está restringida.

Ventajas del plástico en láminas GAG

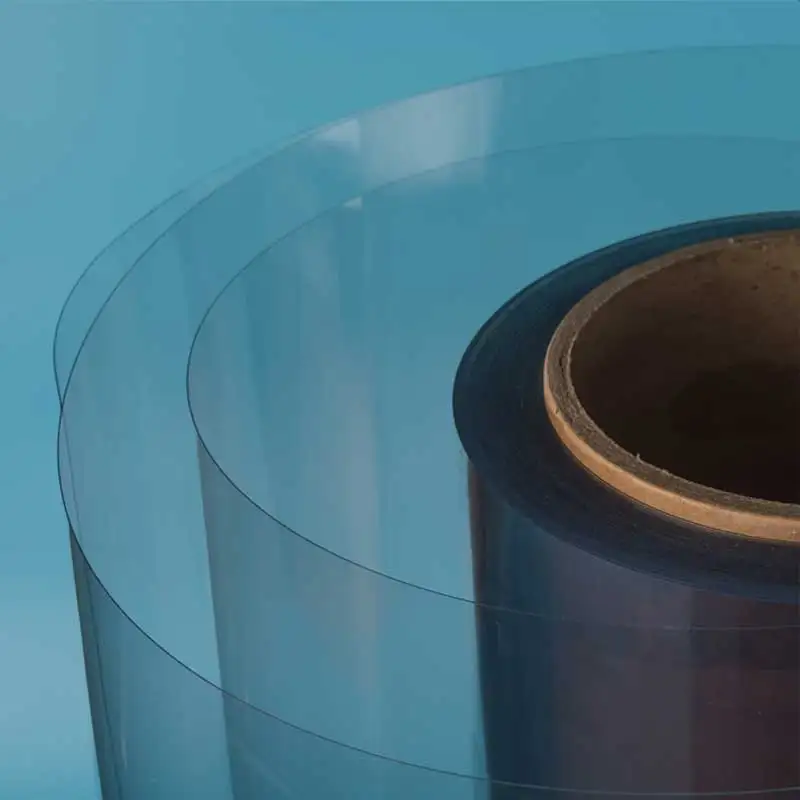

La transparencia puede alcanzar más del 90% y la textura es buena, adecuada para productos que requieren alta transparencia.

El material de la lámina GAG es duro y duradero, adecuado para aplicaciones con alta resistencia al impacto.

Se pueden utilizar métodos de procesamiento como aserrado, troquelado, taladrado y corte por láser, así como doblado en frío y en caliente, unión, soldadura y pulido, impresión y recubrimiento.

Se puede moldear sin precalentar, con alta precisión, con una tasa de contracción de aproximadamente el 0,5%, el producto terminado no es fácil de romper y el espesor es uniforme.

Puede reciclarse y utilizarse sin contaminar el medio ambiente.

Aplicaciones de la hoja GAG

La lámina GAG es un material de muy alta calidad, que puede desempeñar un papel muy importante en la vida después del procesamiento del blister. Comúnmente utilizado en materiales de embalaje como bandejas y cajas blister.