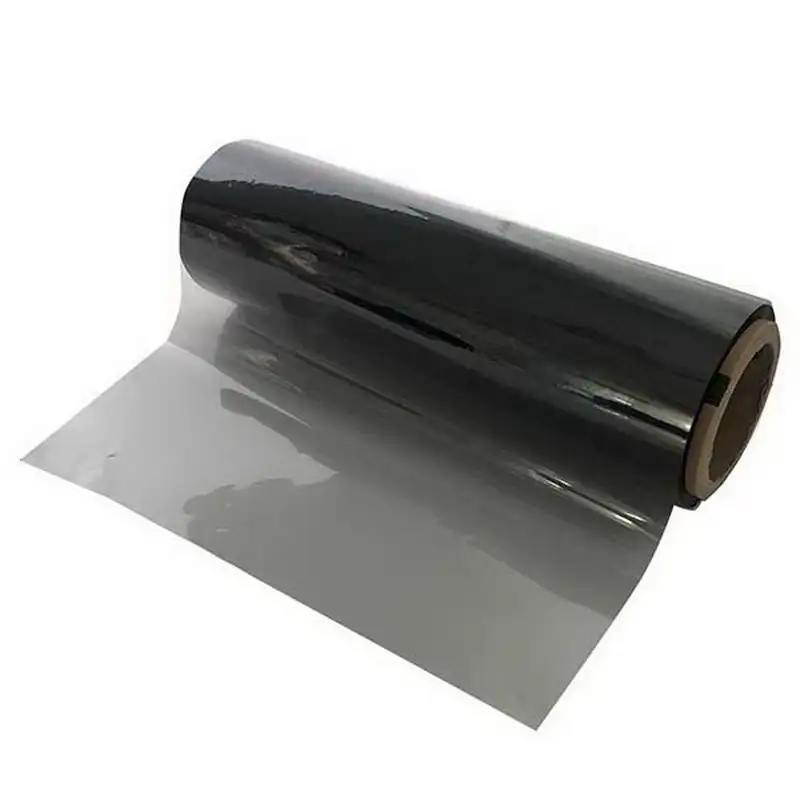

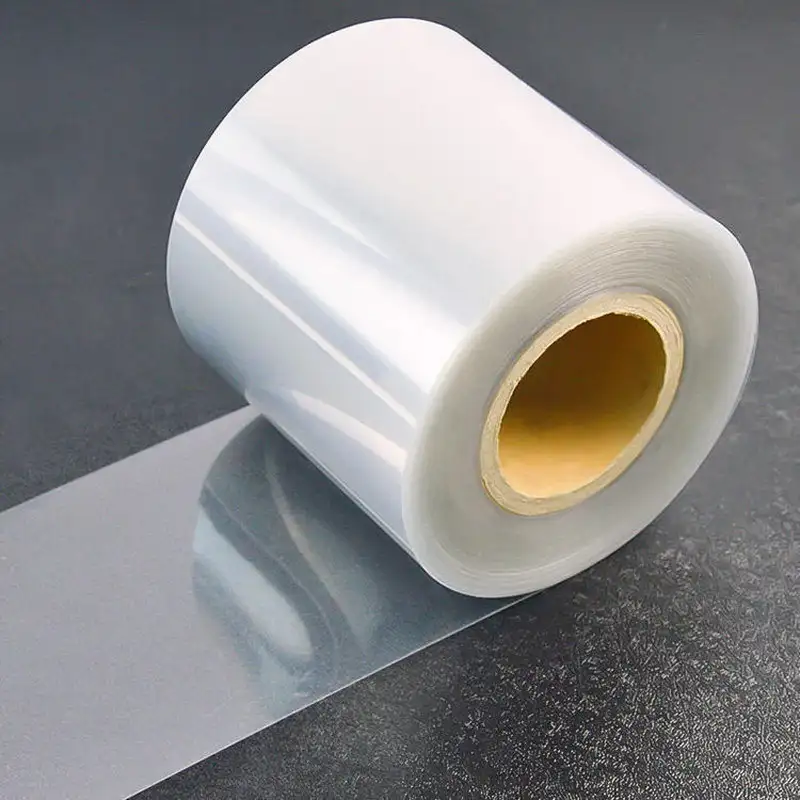

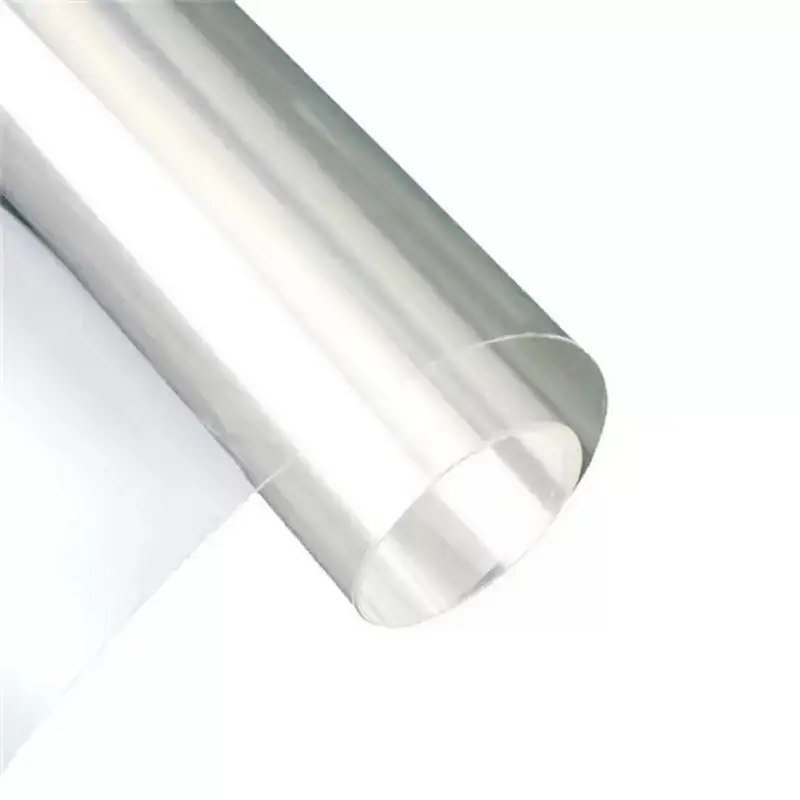

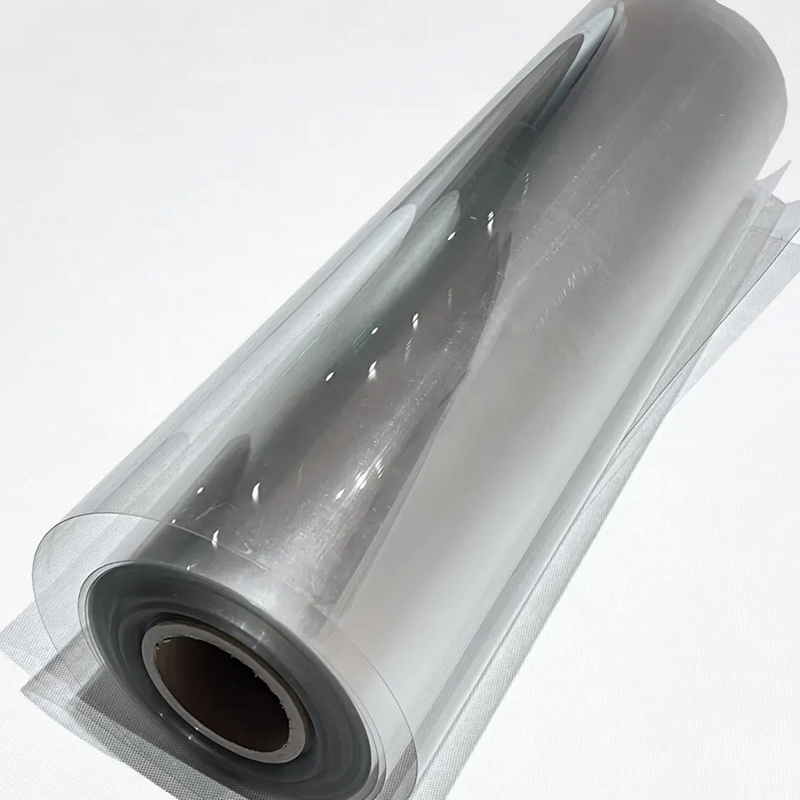

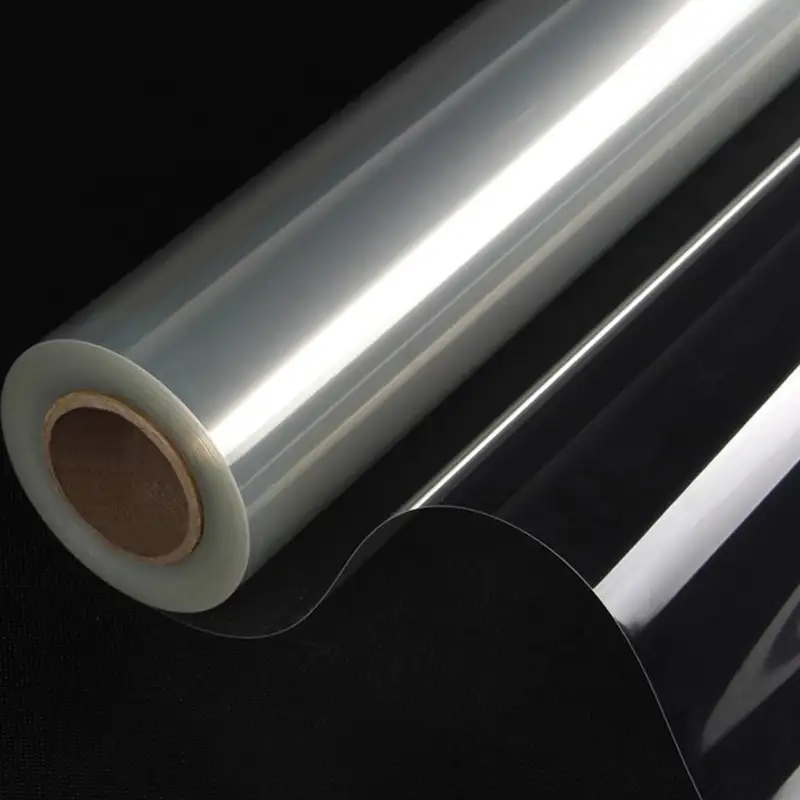

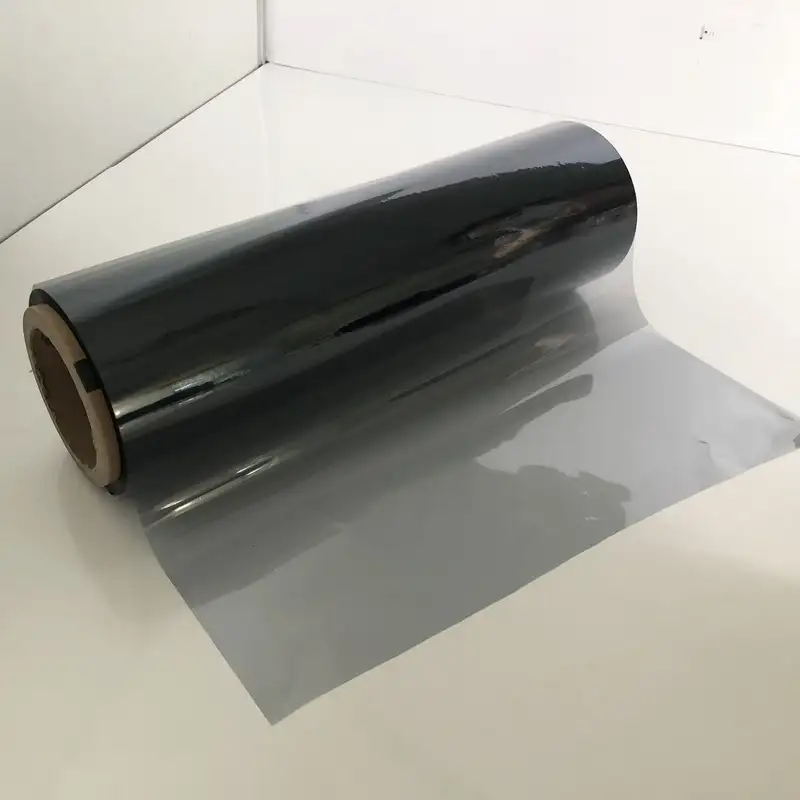

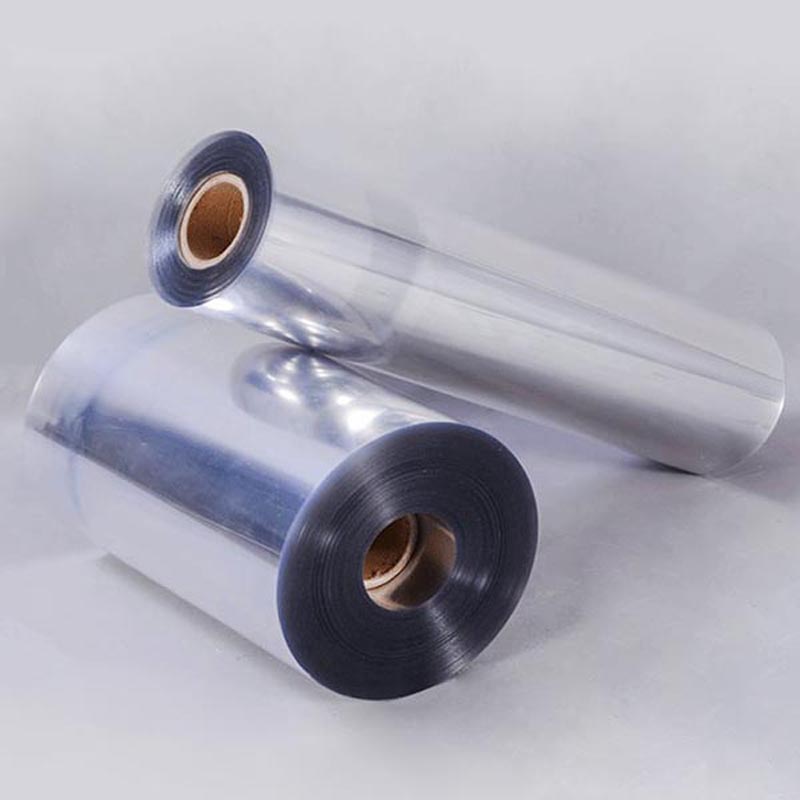

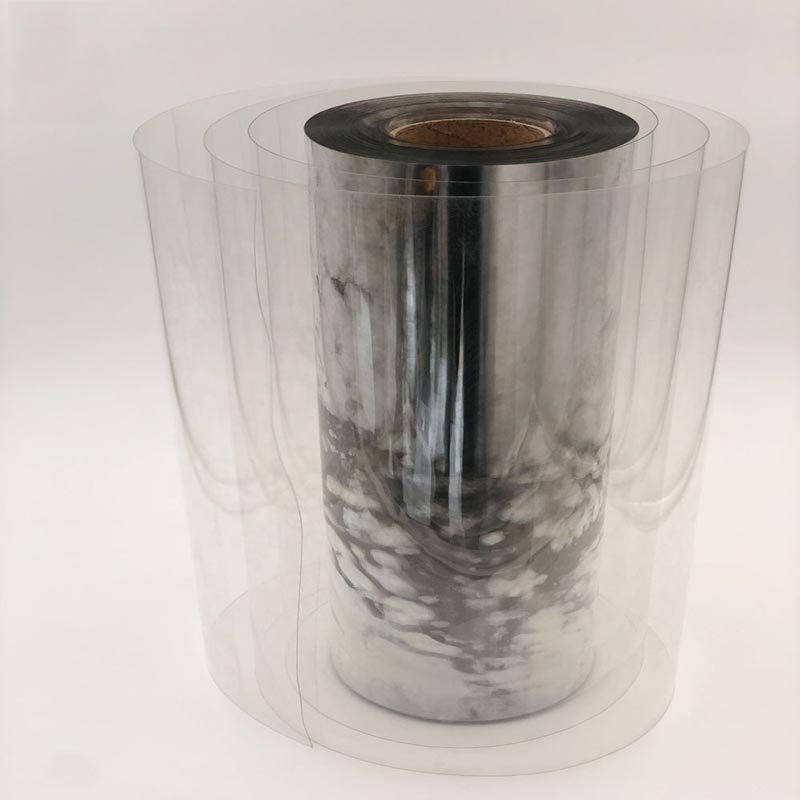

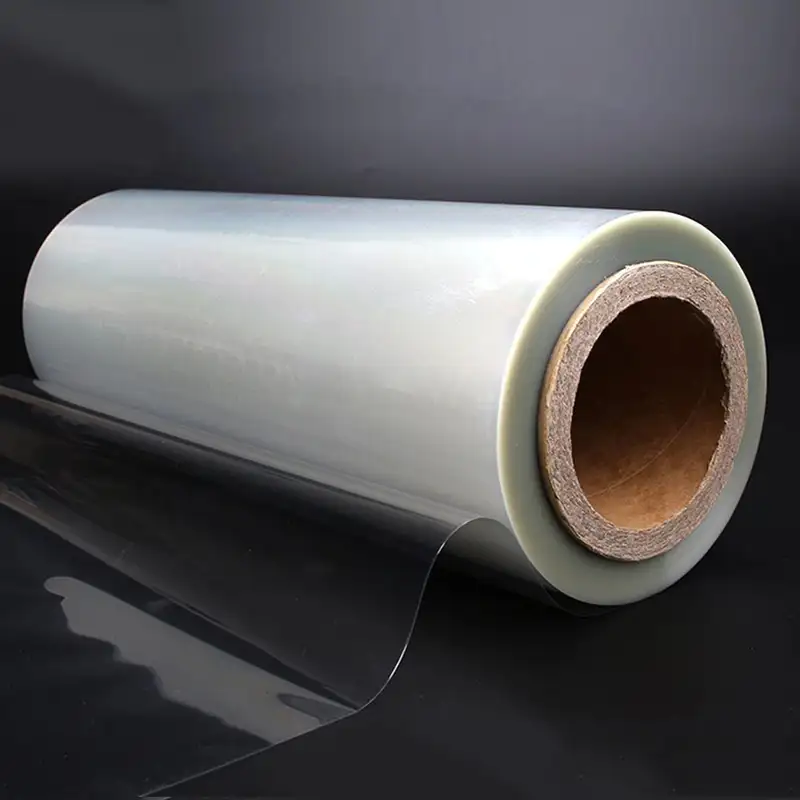

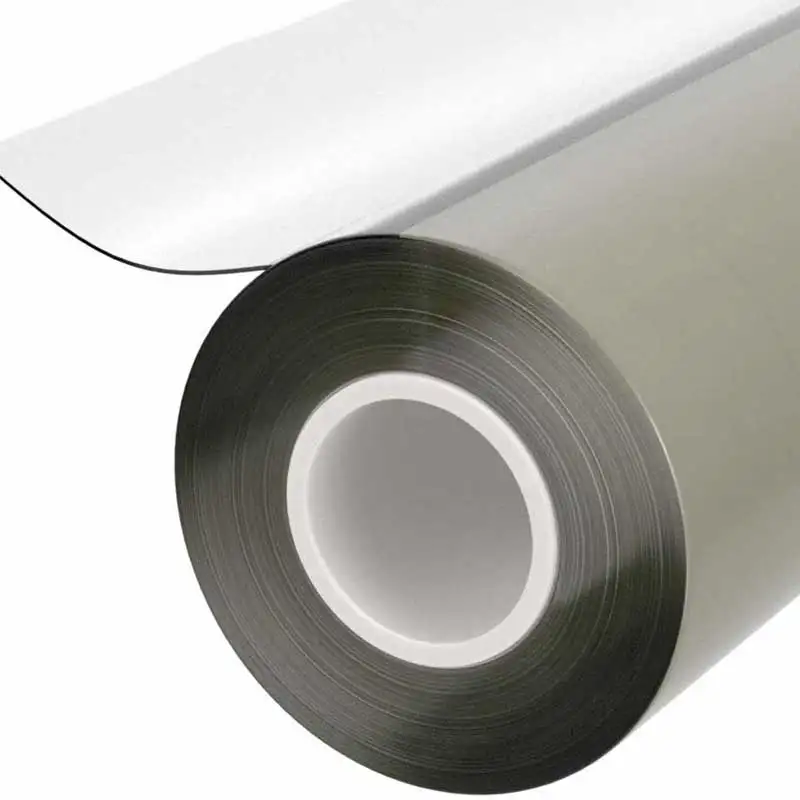

APET Sheet Roll

Pet-sheet.com (Desu Plastic) is a very top Manufacturer & factory of APET Sheet Roll in China. We have advanced technology & equipment, lot of export and international trade experience. Free samples, OEM & ODM accepted

| Product Name: | APET Sheet Roll |

| Manufacturer: | Desu Plastic(pet-sheet.com) |

| Production Process: | Multilayer Co-Extrusion Squeeze Out |

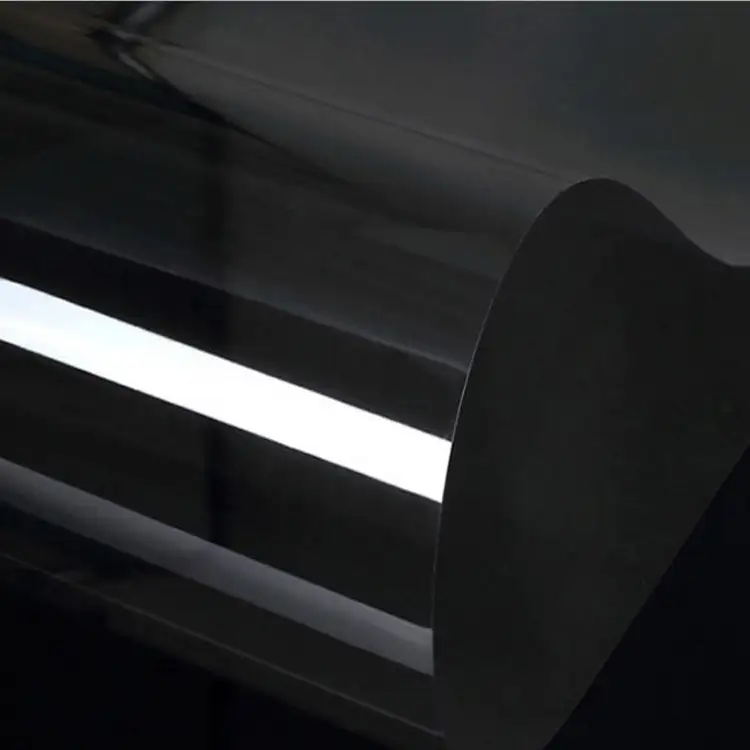

| Specification: | Size: 300-1400mm (PET); Thickness: 0.18-1.8mm; Packaging: Maximum 150kg/roll; Color: Clear/Transparent/Black/White/Custom Colors |

| Main Applications: | Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging |

| MOQ: | 5 tons (free sample accepted ) |

PET Sheet Category

Basic Knowledge

APET (Amorphous Polyethylene Terephthalate) sheet, chemically named as non-crystalline polyethylene terephthalate, is a kind of blister material. APET blister material polyester sheet is a thermoplastic environmentally friendly plastic product. Its side material and waste can be recycled. The chemical elements it contains are carbon, hydrogen, and oxygen like paper, which is a degradable plastic. After the packaging products made of this material are discarded, they eventually become water and carbon dioxide.

Specification

| Product name | APET Sheet Roll, Amorphous PET Sheet Roll |

| Shape | Roll/Sheet |

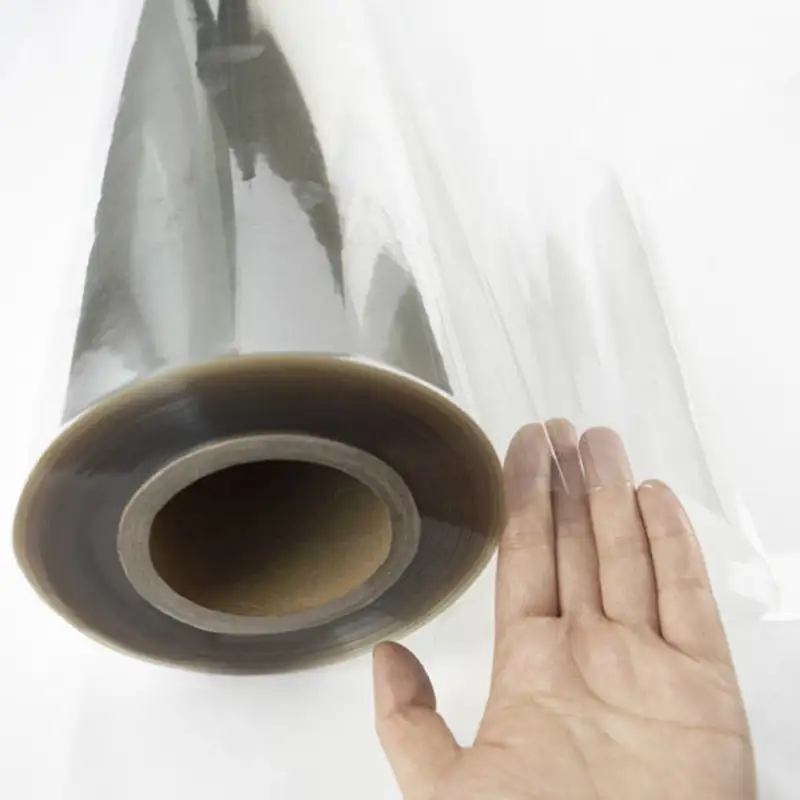

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | 100%Virgin |

| PET Roll Diameter | ≤38 inch |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

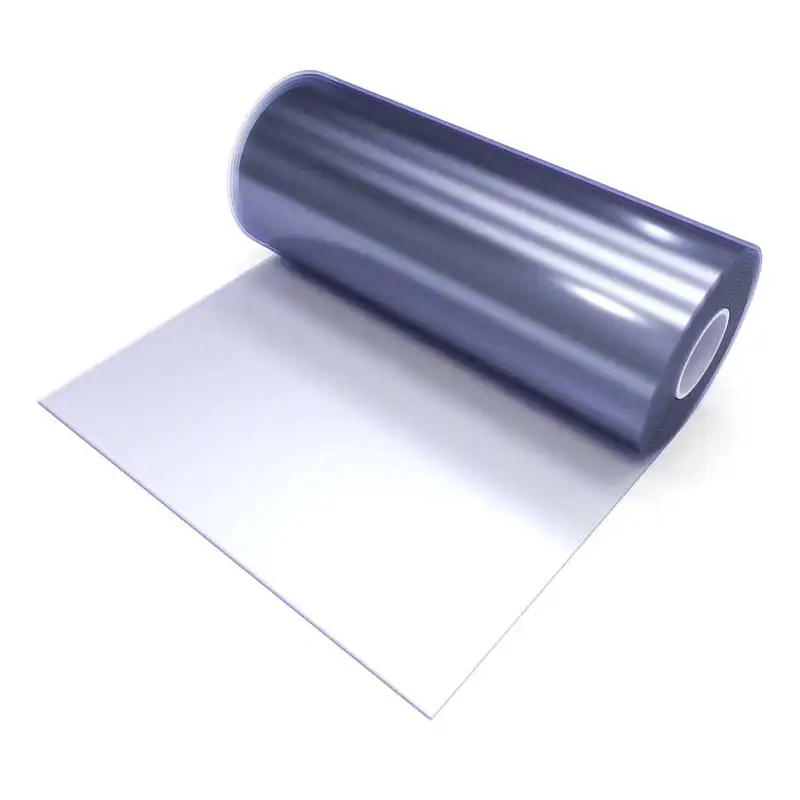

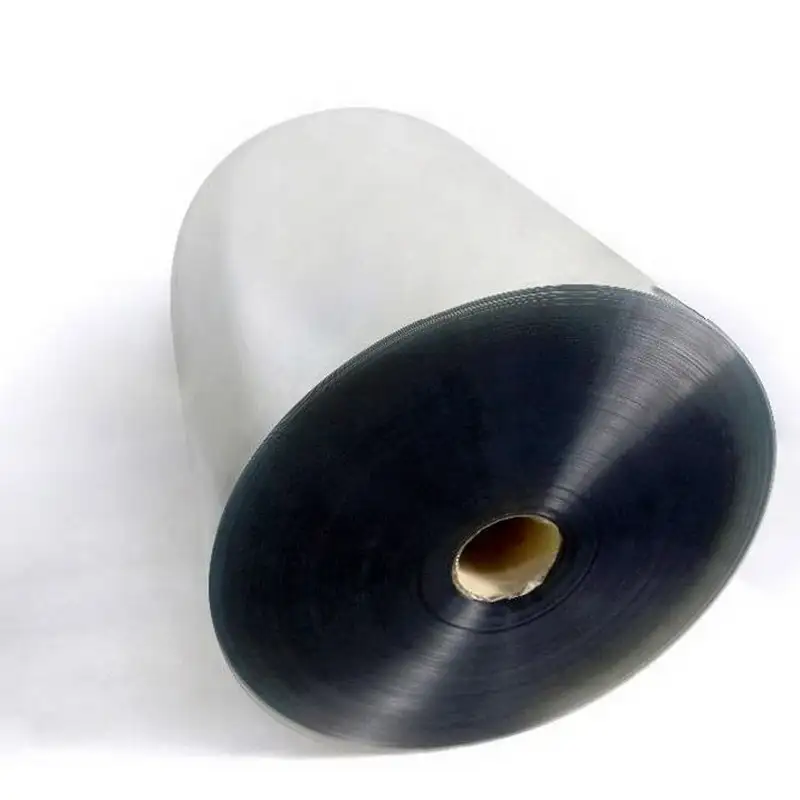

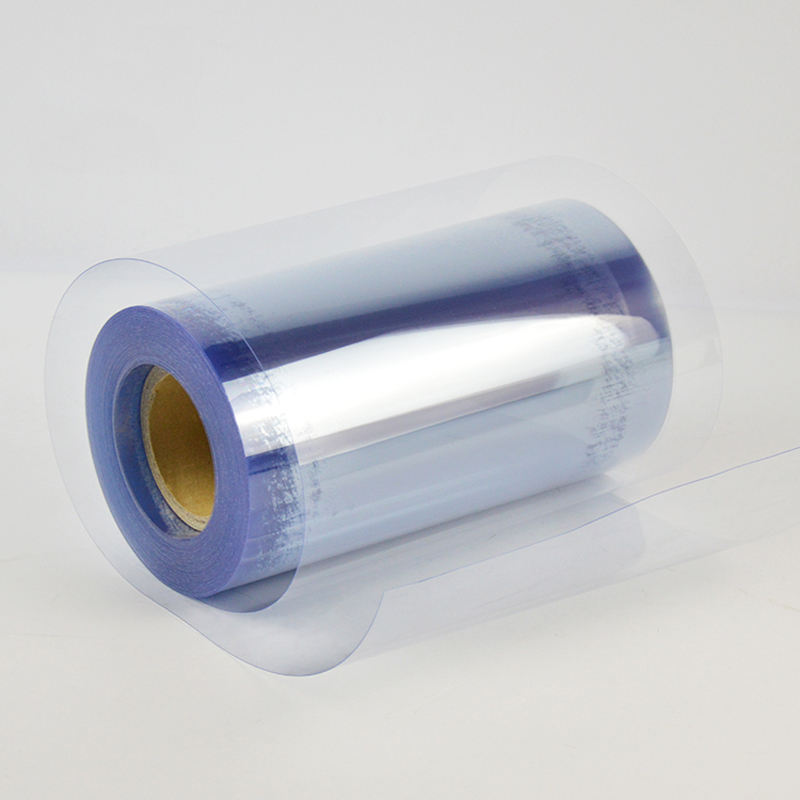

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog; ESD: Anti-static, Conductive, Static dissipative. Printing; Coating; EVOH; Waterproof; etc |

| Processing technology | Thermoforming Vacuum Blister Forming; Die Cutting. |

| Hardness | Rigid / Semi-rigid |

Different Kind Of APET

| Category | Features |

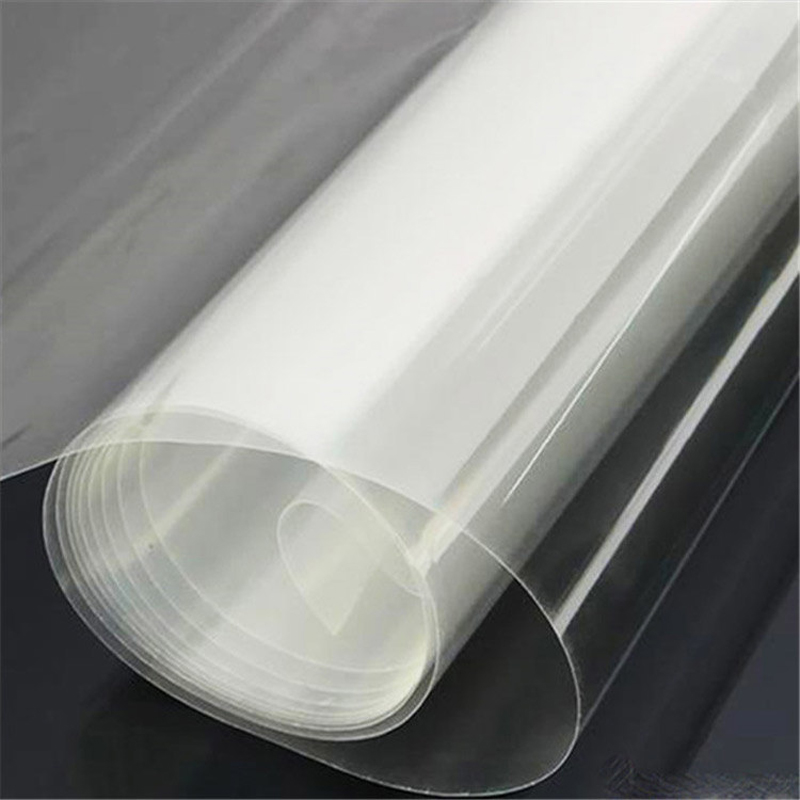

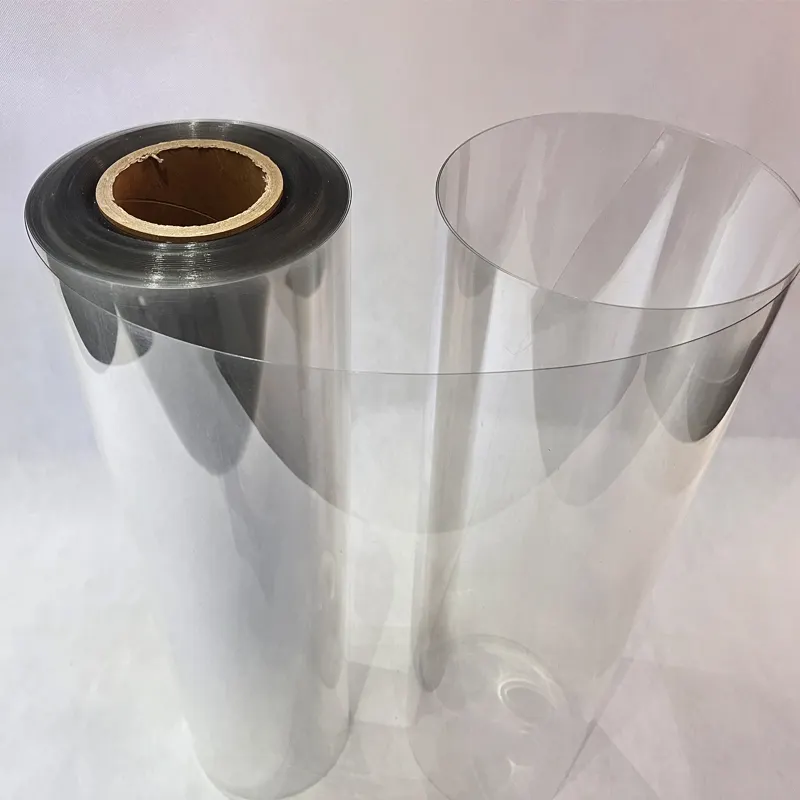

| APET film sheet | Transparent and clean APET ordinary sheet, suitable for folding box, printing and blister. |

| Antistatic sheets | It was divided into three categories, with different levels of antistatic index, suitable for packaging of electronic products with different needs. A grade: Use embedded technology. Antistatic index: 109~1011; B grade : Use coating technology. The antistatic index is: 109~1011; C grade : Use coating technology. The antistatic index is: 108~1010. |

| Conductive sheet | Used for high-end electronic product packaging and turnover boxes, inner support, outer packaging, etc. |

| Color film sheet | Transparent or opaque sheets of various colors are suitable for packaging with high requirements for cosmetics and food. |

| Cutting sheet | After the sheet is formed, it is directly cut into APET flat sheets of the required size with a high-precision cutting machine. |

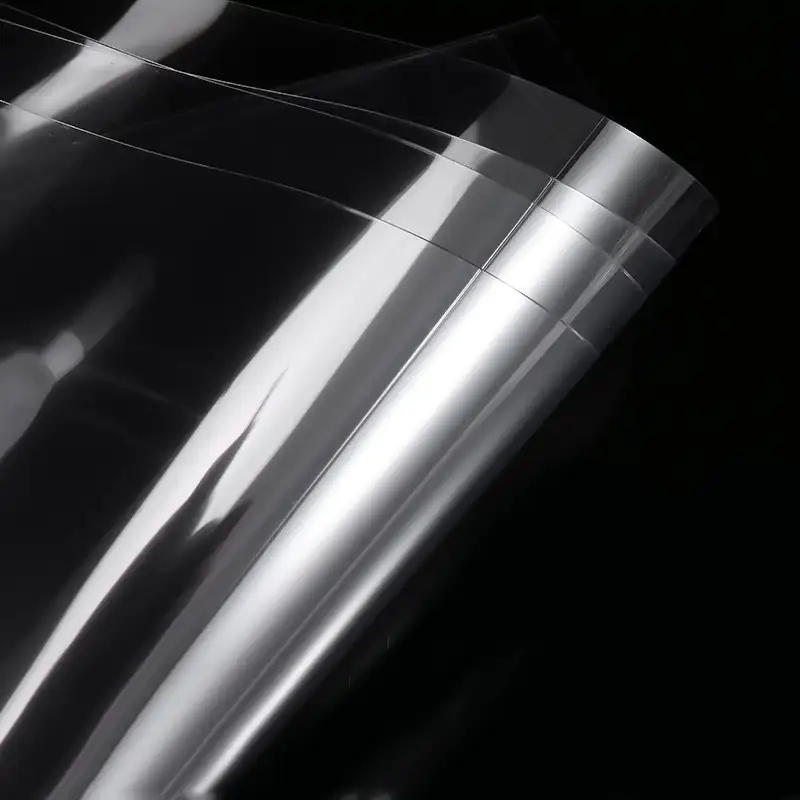

| Laminated sheet | After the APET extruded sheet is formed, it is immediately covered with a transparent protective film. It can be laminated on one side or on both sides. It is suitable for packaging or printing with extremely high requirements on the surface of the sheet. |

| Anti-UV sheet | The anti-ultraviolet APET sheet is especially suitable for outdoor products. |

Physical and Chemical Properties

| Heat Resistance (Continuous) | 115℃ |

| Heat Resistance (Short) | 160℃ |

| Linear Thermal Expansion Coefficient | Average 23-100℃, 60*10-6m/(m.k) |

| Combusti Bility (UL94) | HB |

| Bibulous Rate (23℃ water soak for 24 hours) | 6% |

| Bending Tensile Stress | 90MPa |

| Breaking Tensile Strain | 15% |

| The Tensile Modulus of Elasticity | 3700MPa |

| Normal Strain Compressive Stress (-1%/2%) | 26/51MPa |

| Gap Pendulum Impact Test | 2kJ/m2 |

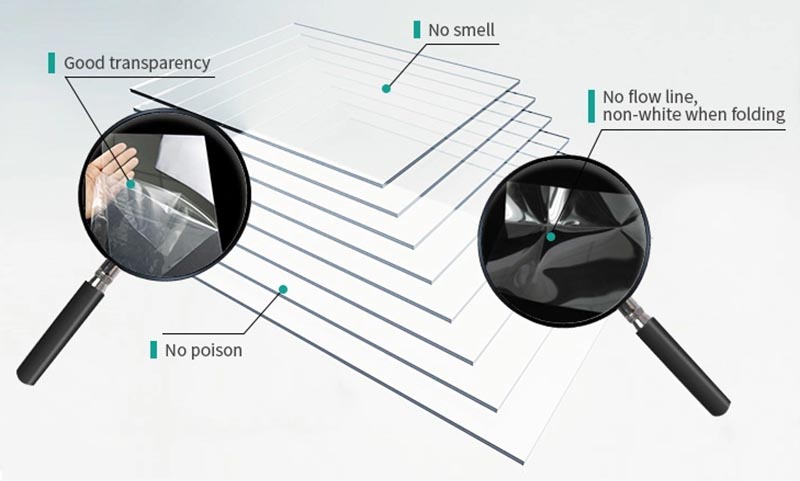

Advantage of PET Sheet

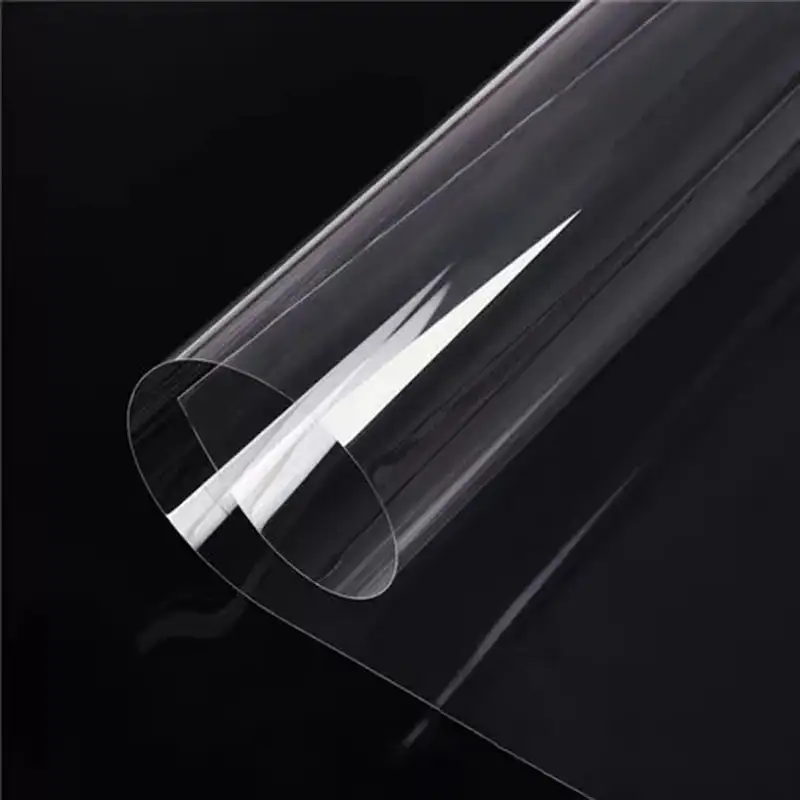

- Good thermoforming properties.

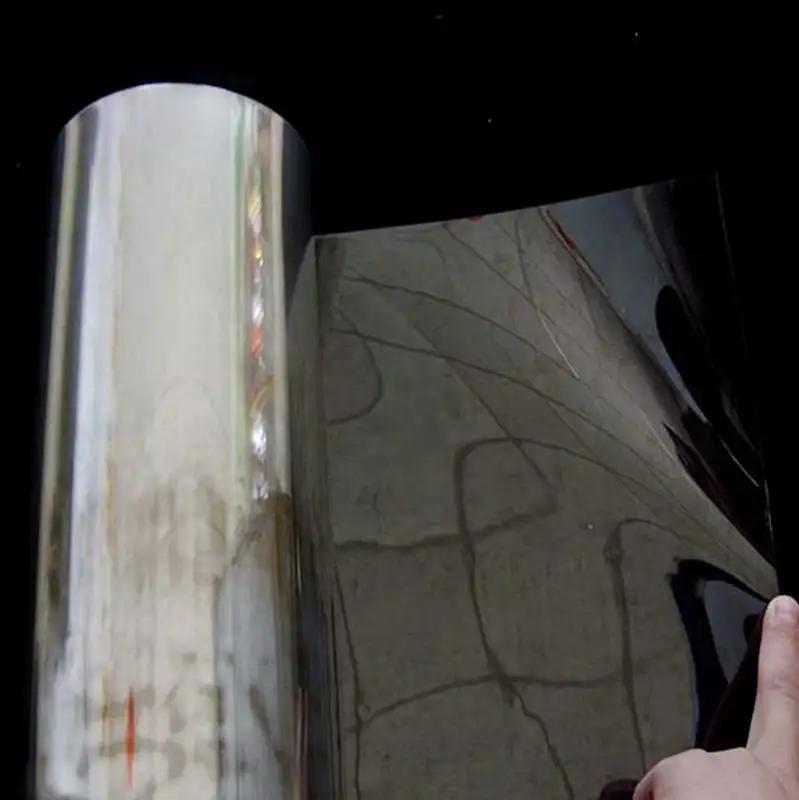

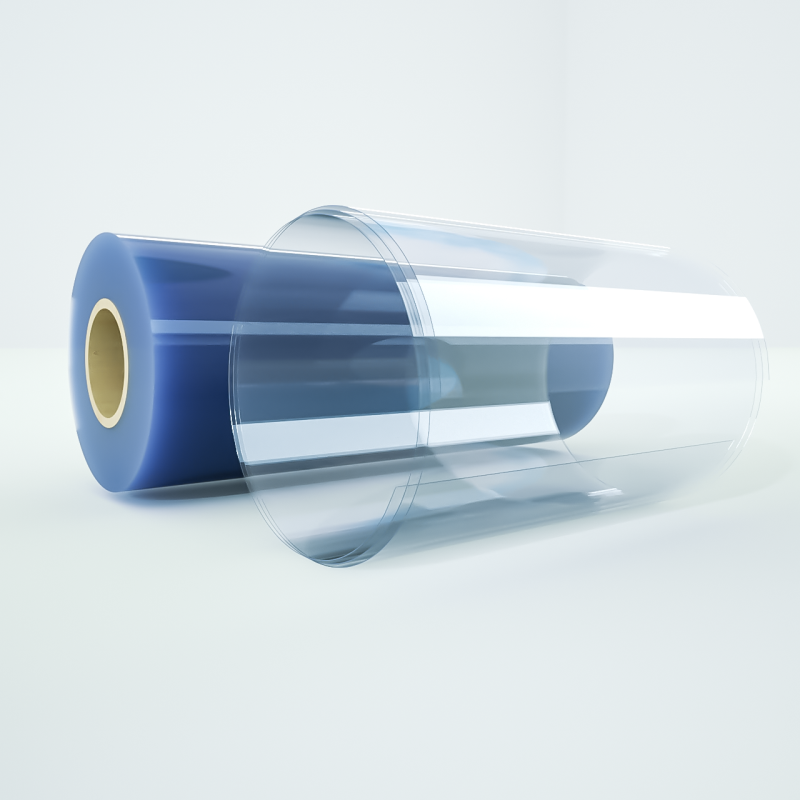

- High transparency.

- Non-toxic, environmentally friendly and pollution-free.

- High gloss.

- Good mechanical properties.

- Good barrier performance.

- Good low temperature resistance.

- Good friction resistance.

- Good printing performance.

- Easy to metallize.

- Recyclable.

Main Application Of APET Sheet

APET sheet has good thermoforming properties. PET products have no pollution, no crystal points, high transparency, good finish, and strong impact resistance. It can be widely used in blister, folding boxes, cylinders and other exquisite packaging and various printing. We can also produce sheets of various colors according to customer requirements.

Inquiry and Order Guide

| PET Shape | Roll / Sheet |

| Thickness | 0.18mm - 2mm |

| Width | 30mm - 1400mm |

| Color | Clear / Transparent / Custom Color |

| Free Sample | Free sample accepted |

| MOQ | 5 Tons minimum order quantity |

| Packing | Diameter≤38 inch PET Roll / 39 inch high Sheet |

| Port | Shanghai / Ningbo China |

| Delivery Time | 7 - 12 Days to delivery |

| Payment Accepted | D/A, D/P, TT, L/C, Westunion etc. |