Pet-sheet.com (Desu Plastic) is a very top Manufacturer & factory of in China. We have advanced technology & equipment, lot of export and international trade experience. Free samples, OEM & ODM accepted

| Product Name: | |

| Manufacturer: | Desu Plastic(pet-sheet.com) |

| Production Process: | Multilayer Co-Extrusion Squeeze Out |

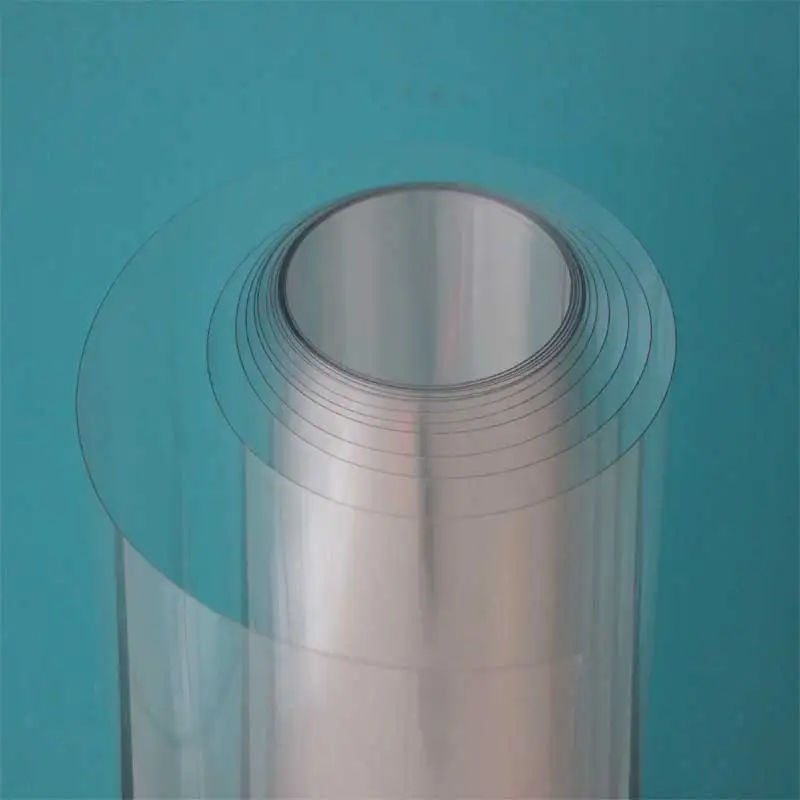

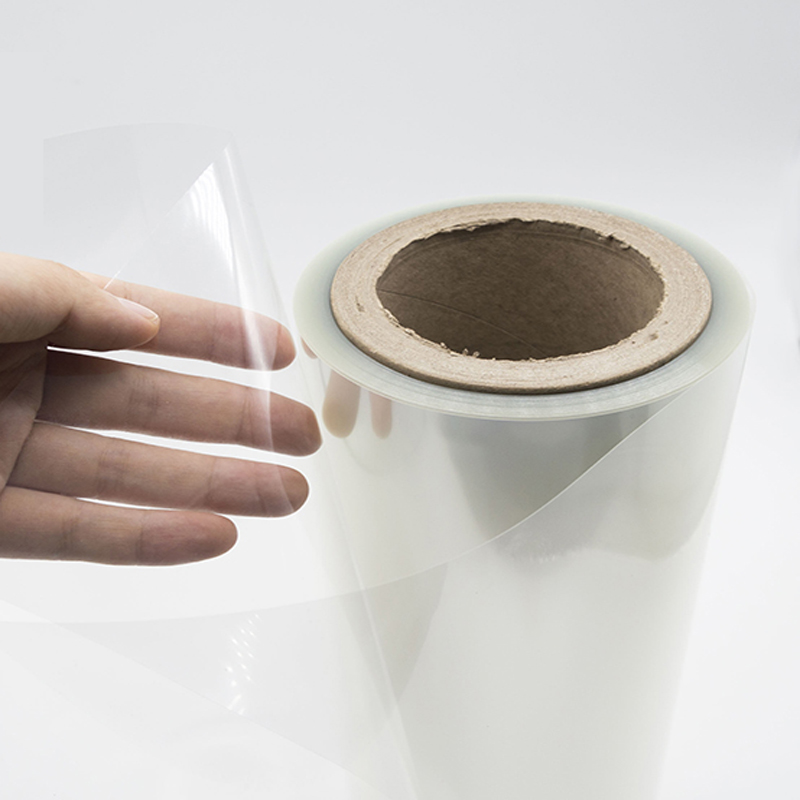

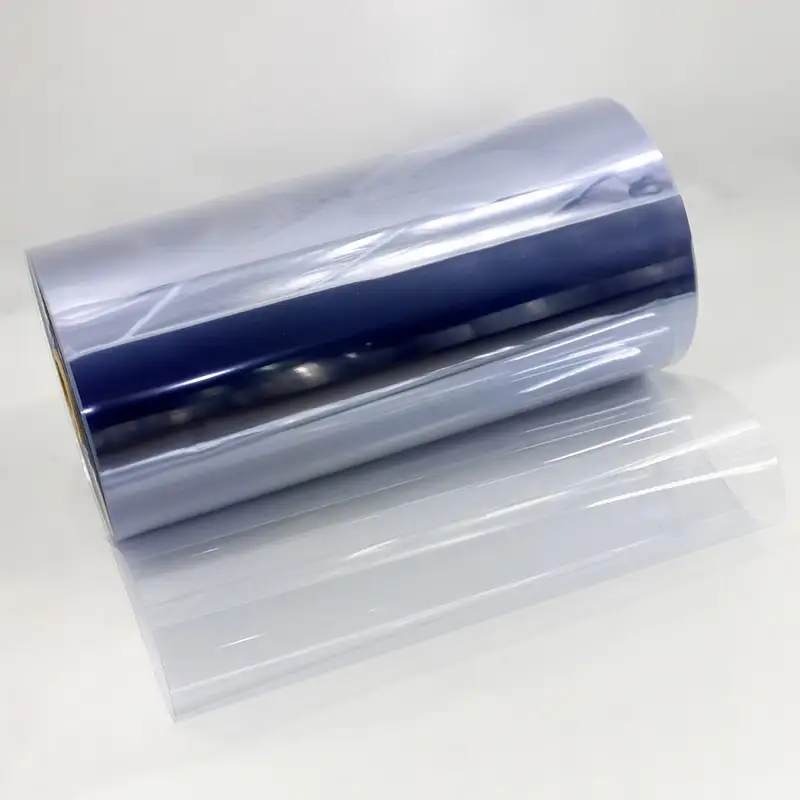

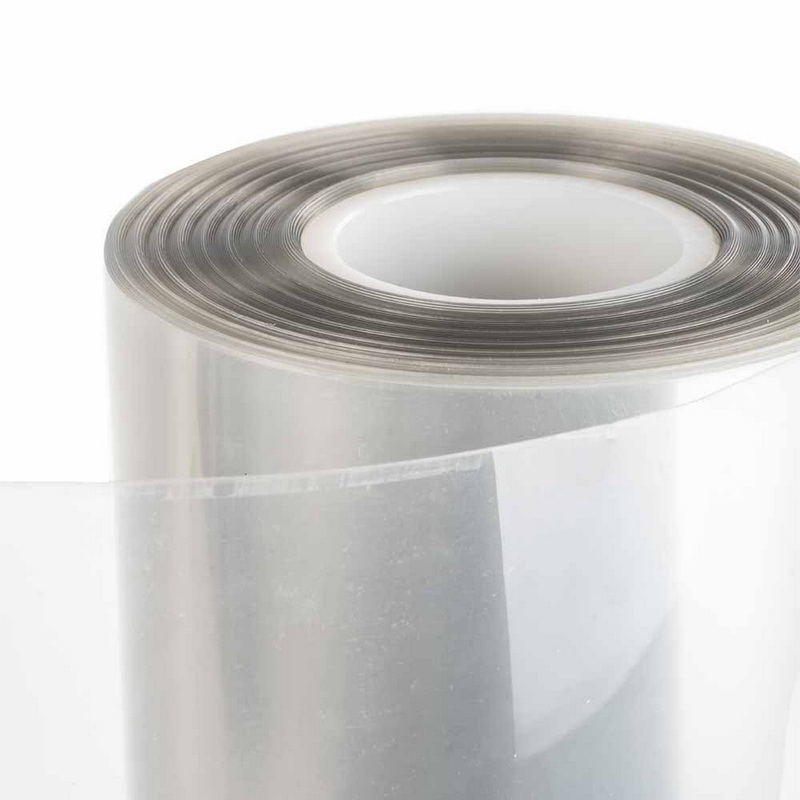

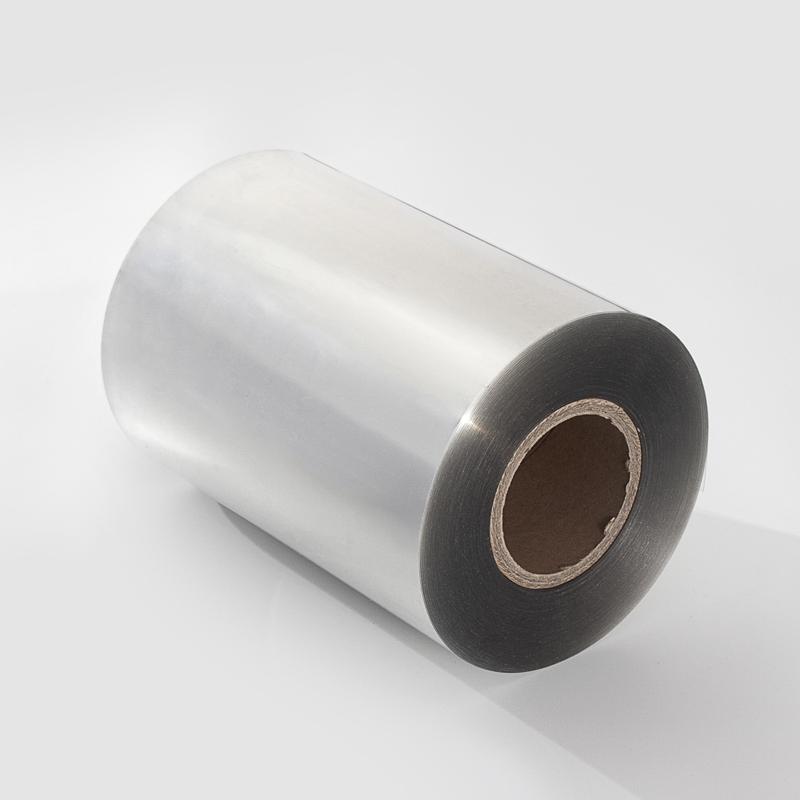

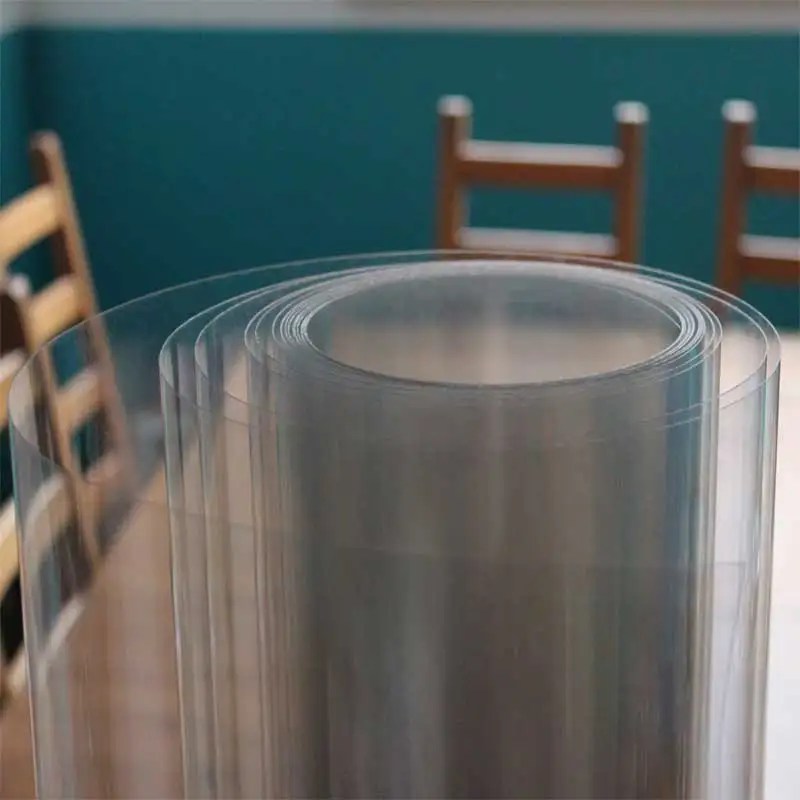

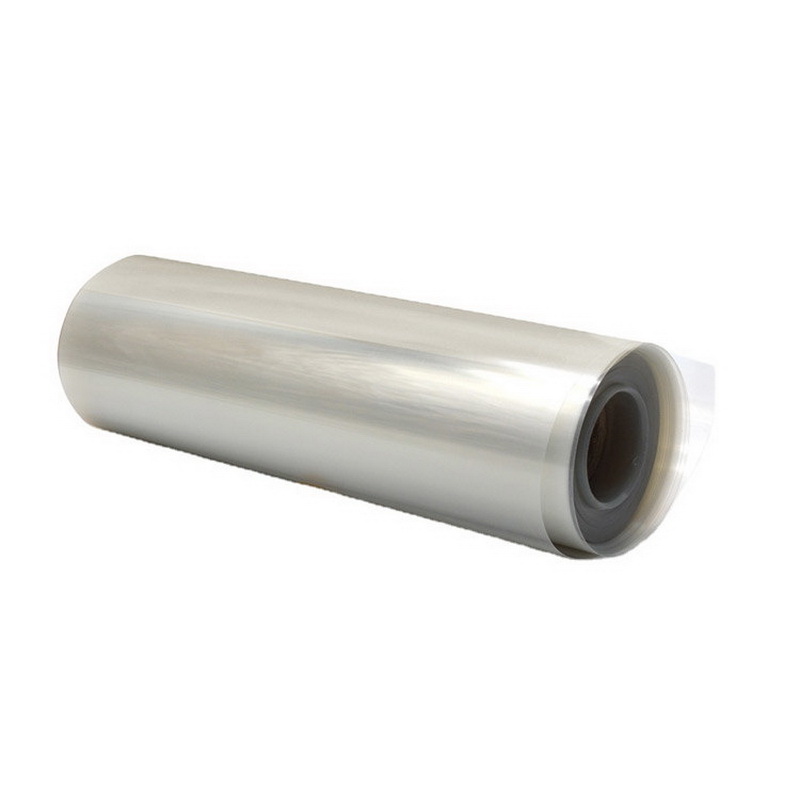

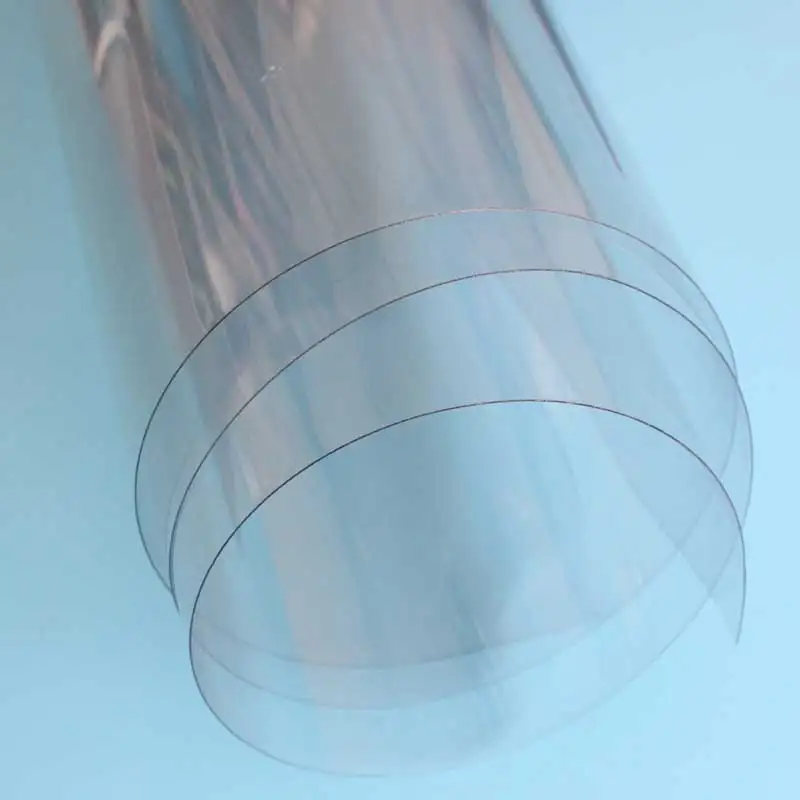

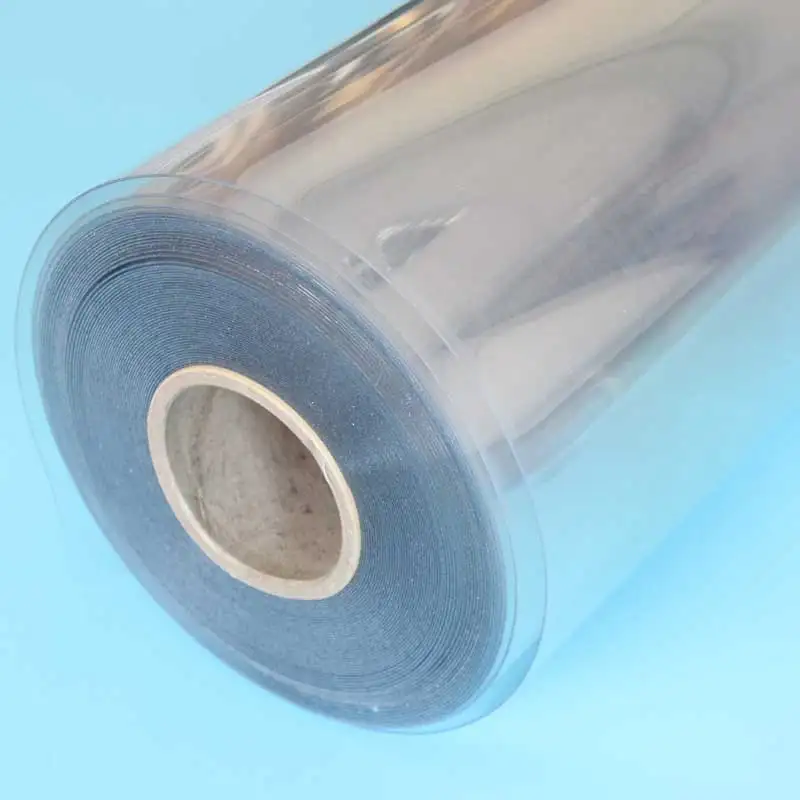

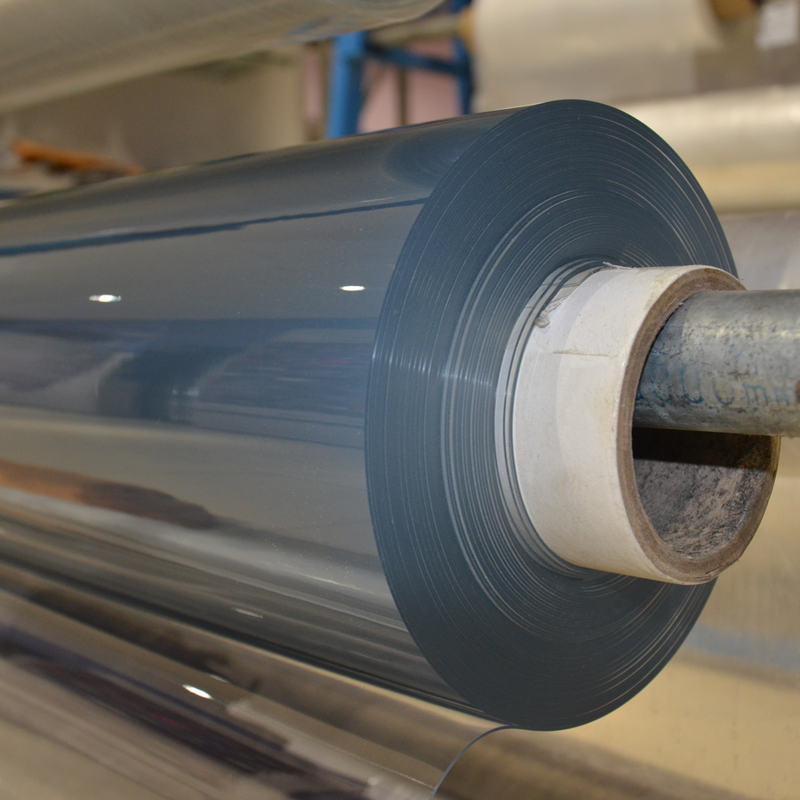

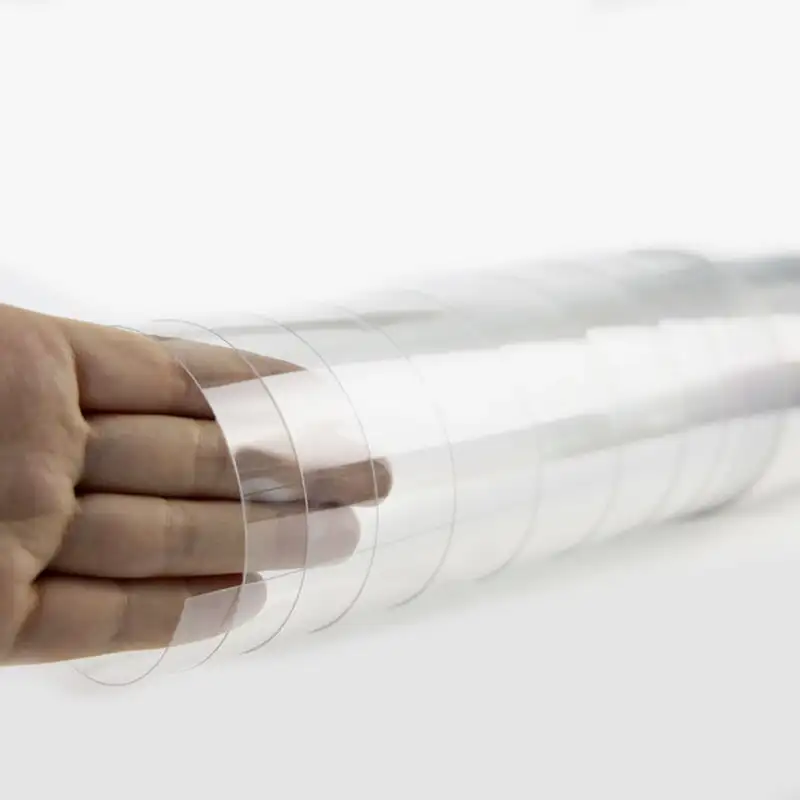

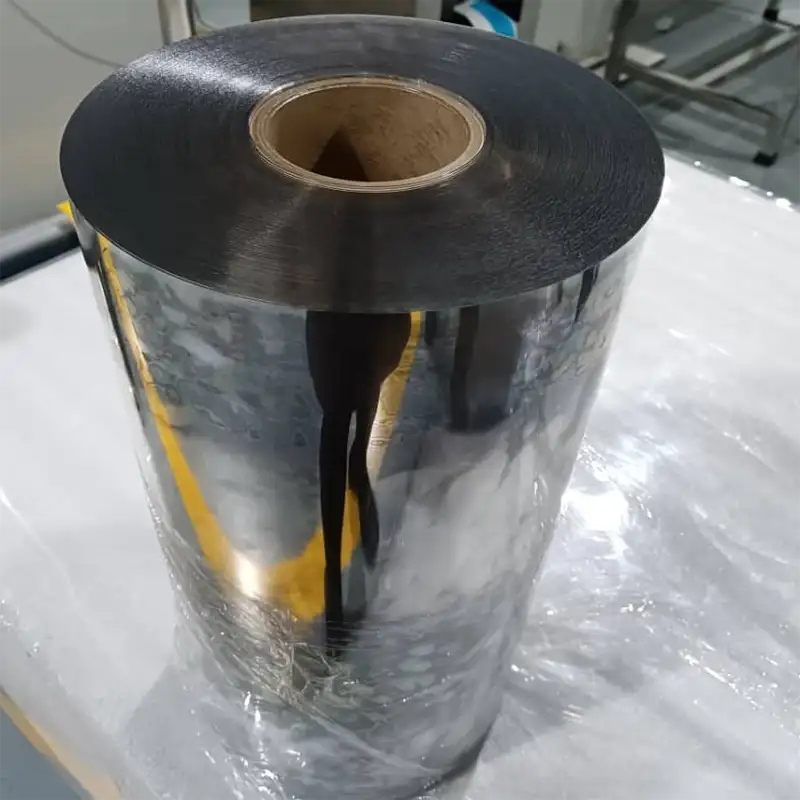

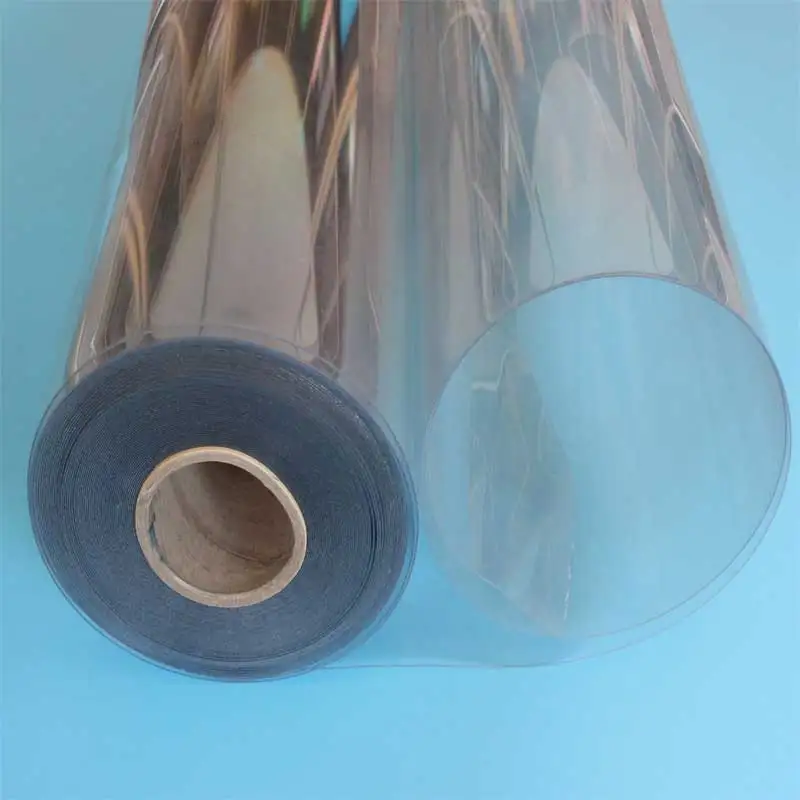

| Specification: | Size: 300-1400mm (PET); Thickness: 0.18-1.8mm; Packaging: Maximum 150kg/roll; Color: Clear/Transparent/Black/White/Custom Colors |

| Main Applications: | Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging |

| MOQ: | 5 tons (free sample accepted ) |

0086-13524363265

PET Sheet Category

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.

Wholesale Transparent Rigid RPET Antifog Film in Rolls

RPET Thermoforming Plastic Sheet Manufactuer and Supplier

PET Sheet for Blister Packaging

RPET Rolls Composite Transparent Film - RPET Laminating Film Bulk

vacuum forming plastic sheet

RPET Sheet Roll for Thermoforming

Wholesale Cheap Plastic RPET Sheet PE Packaging Roll Film Factory

1mm White Plastic Sheet

PET Thermoform Recycling

RPET Thermoforming Film Manufacturer - RPET Transparent Sheet Roll

Rigid R-PET Film

Thermoforming RPET Sheet Roll

PET EVOH Sheet Roll

Food Grade Plastic Rpet Sheet - Blister Rpet Sheet Roll Factory

Recycled PET Sheet Roll

Rigid RPET Sheet Roll For Vacuum Forming - RPET Sheet or Roll Factory

Wholesale High Quality RPET Plastic Sheet Roll For Thermoforming

Customize RPET Film Rolls - Bulk Clear 2mm RPET Sheet Roll In Stock

RPET Sheet Vacuum Packaging Roll - Rpet Transparent Plastic Roll

Clear Rpet Sheet Roll - Custom Color Plastic RPET Sheet Supplier

RPET Plastic Sheet Roll Manufacturer - China RPET Sheet Factory

High Transparent RPET Sheet Roll - Clear Plastic PETG Film Sheet

Rigid RPET Sheet Roll for Thermoforming

Bulk Static Dissipative RPET Sheet Roll - RPET Blister Pack Sheet

ESD Polyethylene Terephthalate Plastic Sheet PET Recycled

Bulk High Quality Plastic PETG Sheet Roll For Thermoforming

0.5mm RPET Plastic Sheet Rolls - Rpet Thermoform Plastic Sheets

Vacuum Forming Rpet Plastic Sheet Colored Factory Price 0.2-2mm

Wholesale Cheap Thermoforming RPET Sheet Roll Plastic From China Factory