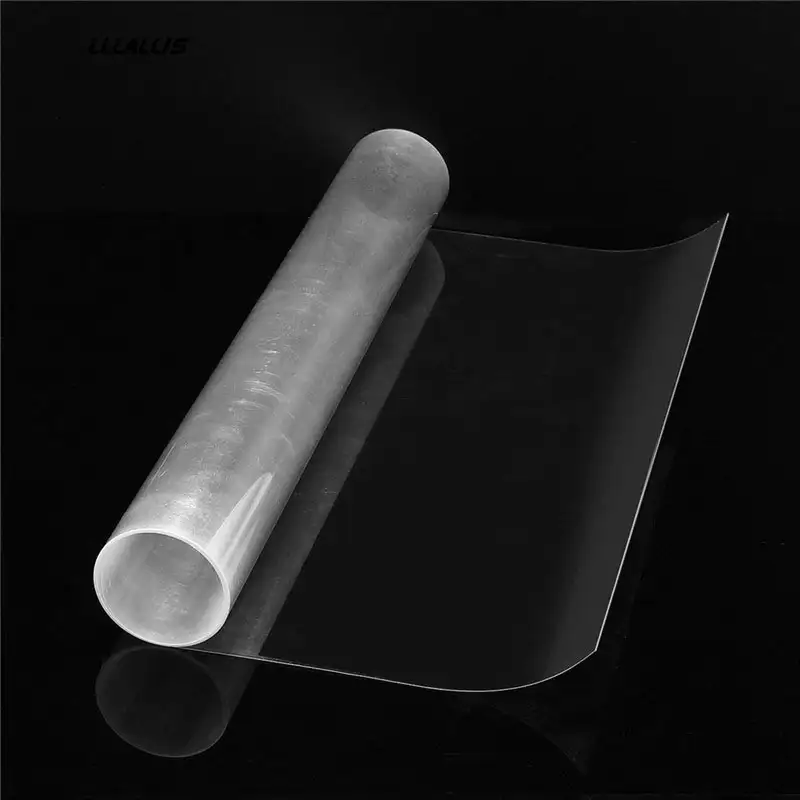

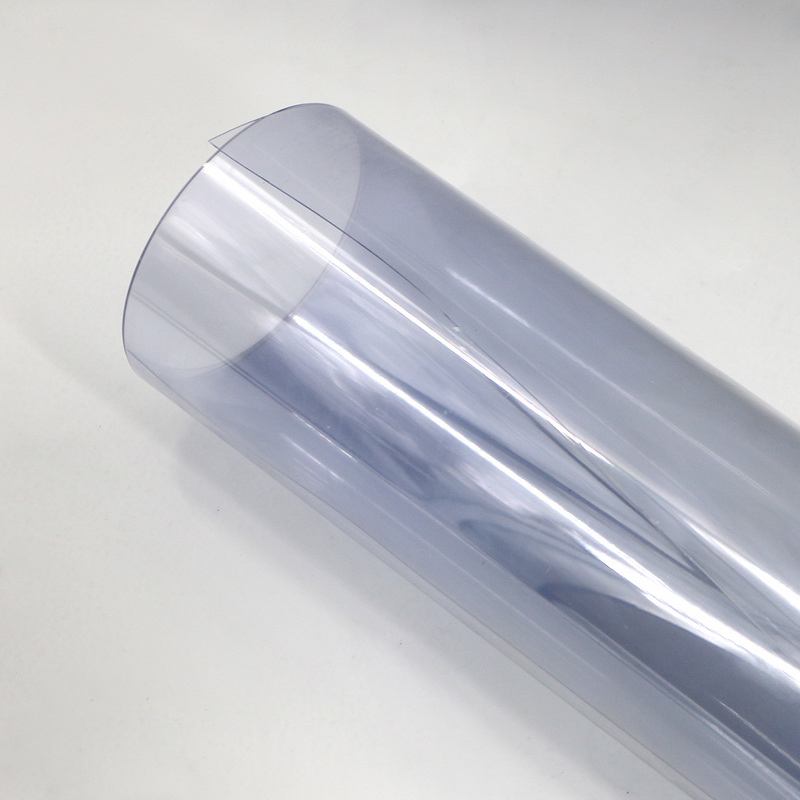

Are you looking for this? . pet-sheet.com belongs to pet-sheet.com, A factory focus on Manufacturer and Export rigid for thermoforming or blister packaging. As to "", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Why Choose pet-sheet.com

If you want to find Manufacturer, Factory & supplier who produce and wholesale . Come here to pet-sheet.com(Shanghai), the one-stop manufacturer wholesaler and exporter for you.

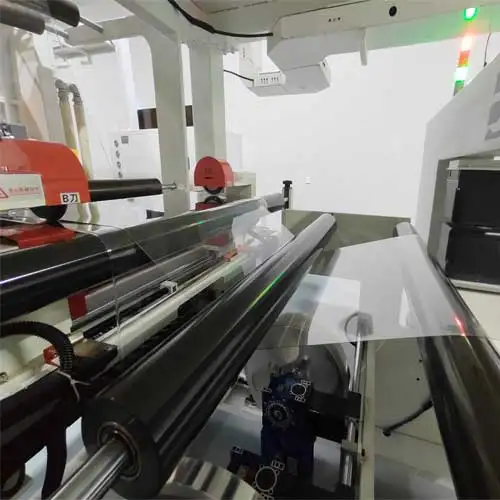

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- PETG Sheet Roll

- GAG Sheet Roll

- ESD Antistatic PET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

Warning: mysqli_fetch_assoc() expects parameter 1 to be mysqli_result, bool given in /home/wwwroot/es.pet-sheet.com/productdetail.php on line 371