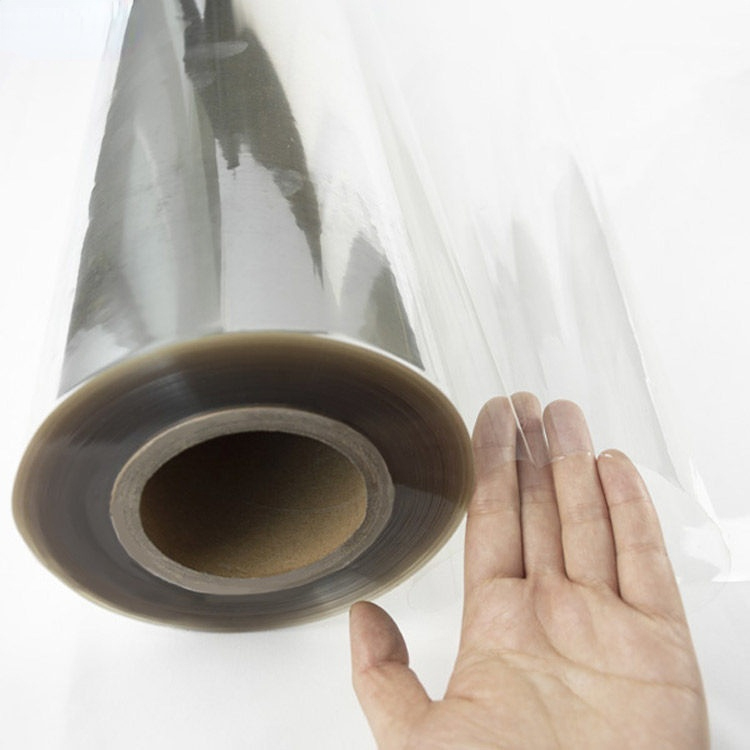

0.9mm PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "0.9mm PET Plastic Rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

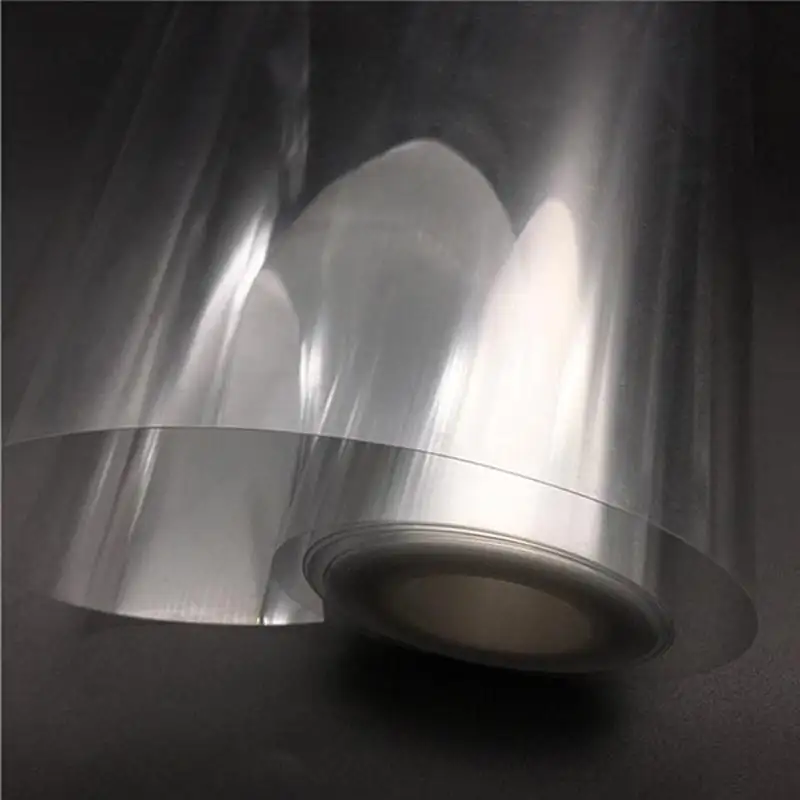

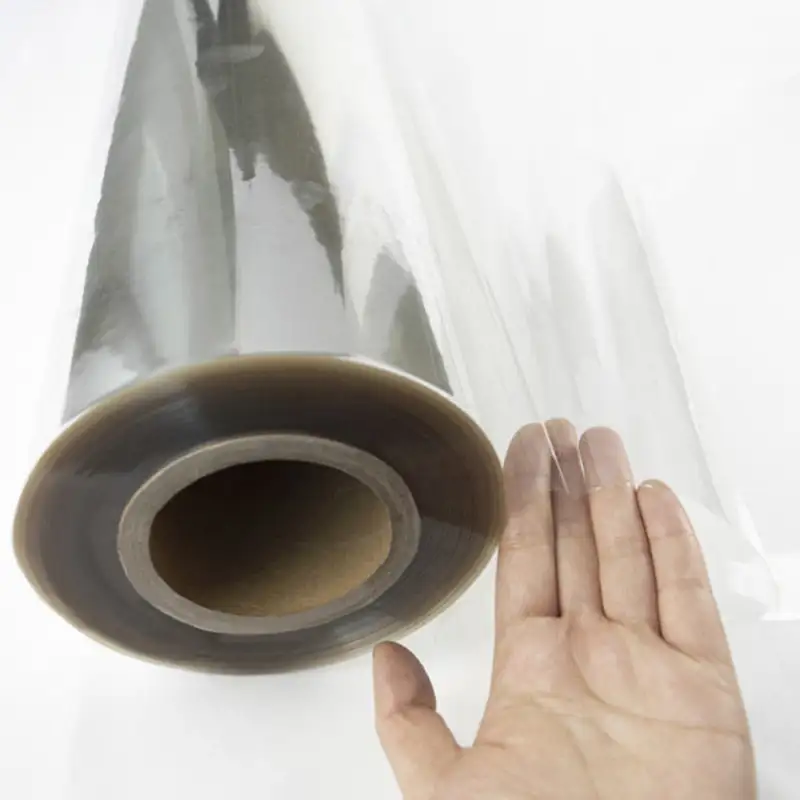

Product Introduction of 0.9mm PET Plastic Rolls

0.9mm PET (Polyethylene Terephthalate) Plastic Rolls are high-performance, eco-friendly thermoforming materials designed for a wide range of packaging applications. Manufactured using advanced extrusion technology, these rolls offer excellent clarity, strength, and stability, making them ideal for both food grade and industrial packaging.

Made from 100% virgin or recycled PET raw materials, our 0.9mm PET rolls are lightweight yet durable, ensuring optimal protection for the packaged products while maintaining transparency and visual appeal.

Product Advantages of 0.9mm PET Plastic Rolls

1. Optimal Thickness for Durability

The 0.9mm thickness provides excellent impact resistance and structural strength, making it ideal for medium to heavy-duty thermoforming applications.

2. High Clarity and Gloss

Offers superior transparency and a glossy finish, allowing for clear product visibility and attractive packaging presentation.

3. Food-Grade Safety

Non-toxic and compliant with food contact safety standards, suitable for direct food packaging.

4. Excellent Thermoformability

Ensures smooth and consistent forming with sharp detail definition, enhancing product protection and shelf appeal.

5. Superior Chemical Resistance

Resistant to oils, acids, and most chemicals, ensuring longer shelf life for packaged goods.

6. Eco-Friendly and Recyclable

100% recyclable material, supporting sustainable and environmentally responsible packaging solutions.

7. Good Barrier Properties

Offers good resistance to moisture and oxygen, helping maintain product freshness and integrity.

8. Smooth Surface for Printing and Laminating

Ideal for high quality printing, coating, and laminating processes to meet branding and labeling requirements.

Product Application of 0.9mm PET Plastic Rolls

0.9mm PET plastic rolls can be used for packaging a variety of products, including but not limited to:

1. Food Packaging: Trays, clamshells, containers, and lids for fresh produce, baked goods, or ready-to-eat meals.

2. Blister Packs: For pharmaceuticals, electronics, or small consumer goods.

3. Clamshell Packaging: Retail packaging for electronics, toys, hardware, or cosmetics.

4. Thermoformed Trays: Meat, poultry, seafood, or dairy product packaging.

5. Display Packaging: Point-of-sale (POS) displays or promotional packaging.

6. Industrial Packaging: Protective inserts or trays for machinery parts and components.

7. Medical Packaging: Sterile trays or containers for medical devices and instruments.

8. Consumer Goods Packaging: Clear or printed packaging for stationery, tools, and small household items.

Product Processing of 0.9mm PET Plastic Rolls

The production of 0.9mm PET (Polyethylene Terephthalate) plastic rolls involves several precise and controlled steps to ensure high clarity, durability, and consistent thickness.

1. Raw Material Preparation

High quality PET resin (virgin or recycled) is selected and dried to remove moisture. Proper drying is critical to avoid defects like bubbles or hazing during extrusion.

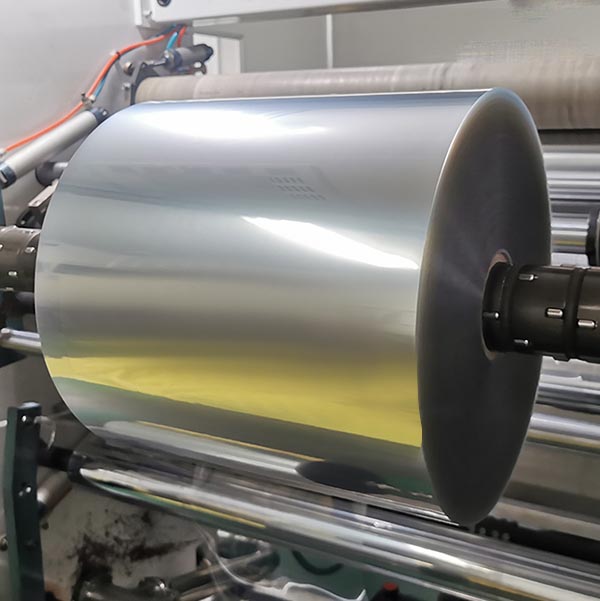

2. Extrusion

The dried PET pellets are fed into an extruder, where they are melted at high temperatures (typically 250°C to 280°C). The molten PET is then forced through a flat die to form a continuous sheet.

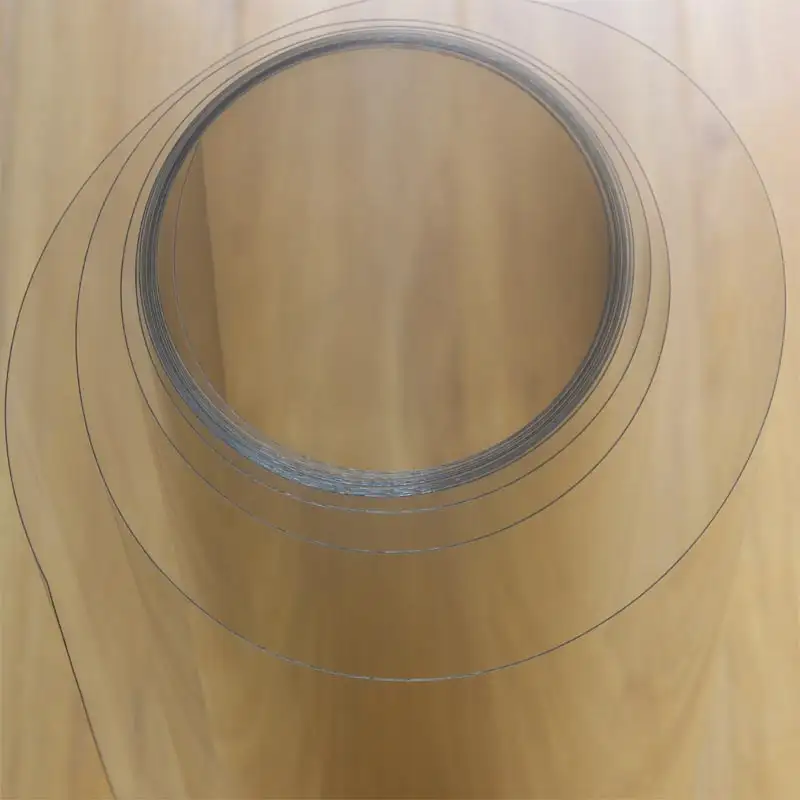

3. Calendering / Rolling

The extruded PET sheet passes through a series of precision rollers (calendering rolls) to:

- Control the thickness precisely to 0.9mm

- Achieve uniform surface smoothness

- Enhance mechanical properties

4. Cooling

The sheet is cooled using chilled rollers or a cooling system to solidify the material and maintain dimensional stability.

5. Surface Treatment (Optional)

Depending on the application, the surface may undergo treatments such as:

- Anti-fog coating

- Anti-static treatment

- Matte or glossy finishing

6. Trimming and Slitting

The edges of the sheet are trimmed, and the sheet is slit into desired roll widths to meet customer specifications.

7. Winding

The finished PET sheet is wound into rolls on a core. Tension is controlled to prevent wrinkling or deformation.

8. Inspection & Quality Control

Each roll undergoes strict quality control checks for:

- Thickness uniformity

- Clarity and transparency

- Surface defects

- Roll weight and width accuracy

9. Packaging

The rolls are wrapped in protective films and packed into pallets or cartons for secure transportation and storage.

Why choose Desu 0.9mm PET Plastic Rolls?

Choosing Desu 0.9mm PET Plastic Rolls means selecting quality, reliability, and performance. Here’s why manufacturers and packaging companies worldwide trust Desu:

1. Premium Material Quality

Desu uses high-purity virgin or food-grade recycled PET resin, ensuring excellent transparency, strength, and safety for various packaging applications.

2. Consistent Thickness & Flatness

With precision extrusion and calendering technology, Desu guarantees uniform 0.9mm thickness, excellent flatness, and minimal thickness deviation — ideal for thermoforming and high-speed production lines.

3. Superior Thermoforming Performance

Desu PET rolls offer excellent moldability, deep-draw capabilities, and stable shrinkage rates, making them ideal for forming trays, clamshells, and blister packs.

4. Food-Grade and Eco-Friendly

Compliant with FDA, EU, and SGS standards, Desu’s PET rolls are safe for direct food contact and 100% recyclable — contributing to your sustainability goals.

5. Smooth Surface Finish

Available in glossy, matte, or customized textures, Desu PET rolls provide a premium look and feel, enhancing product presentation.

6. Customization Options

Desu offers custom roll widths, colors (clear, colored, anti-UV), and surface treatments (anti-fog, anti-scratch, anti-static) to meet specific industry needs.

7. Advanced Production Facilities

With multiple modern factories and strict QC processes, Desu ensures high production capacity, fast delivery times, and stable supply, even for large-volume orders.

8. Trusted Manufacturer

Desu has a proven track record in PET sheet production, exporting globally to clients in food, electronics, cosmetics, and medical packaging sectors.

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Food Grade PET Plastic Rolls for Thermoforming Packaging

- Conductive PET plastic rolls

- PET Thermoforming Plastic Rolls

- Blister Packaging PET Plastic Rolls

- PET Plastic Rolls for Bread Trays

- PET sheet roll for Toy packaging

- PET Plastic Sheet Rolls for Packaging Solutions

- 0.8mm Polyethylene Terephthalate Plastic Sheet Rolls

- 0.6mm Polyethylene Terephthalate Plastic Sheet Rolls

- Premium PET Sheet Rolls for Food Tray

- 1.7mm PET Plastic Sheet Rolls

- PET plastic rolls for Toothbrush packaging

- 2.0mm PET Plastic Rolls

- PET Plastic Sheet Rolls for Coffee Cups

- 1.8mm Thermoforming PET Plastic Sheet Rolls

- 1.6mm Thermoforming PET Plastic Rolls

- 1.4mm PET Plastic Sheet Rolls

- 1.3 mm PET plastic rolls

- 1.0mm PET plastic sheet rolls

- 0.7mm PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM