70 Tons PET & PP Thermoforming Sheets Shipped to Mali | DESU

In January 2026, DESU successfully completed the shipment of 70 tons of PET and PP thermoforming plastic sheets to Mali.

These products will be primarily used for the large-scale production of food-grade thermoformed trays and blister packaging, marking the official launch of DESU’s first collaboration with a major packaging manufacturer in the West African market.

As the DESU product manager, I had the privilege of participating in this project from start to finish, from initial customer contact, technical evaluation, sample verification, and factory audit, to the final bulk contract signing and shipment execution. This is not just an order, but the beginning of a partnership based on professional capabilities, supply stability, and long-term trust.

Cooperation Background | The Decision-Making Path from On-Site Inspection to a 70-Ton Contract

Customer Background and Industry Positioning

The customer in this collaboration is a packaging manufacturer in Mali with mature processing capabilities. They have long provided thermoformed trays and transparent blister packaging solutions for food, daily chemical, and consumer goods brands, and have a stable customer base and continuously growing order demand in the regional market.

In the past few years, the customer has faced several key challenges:

- Insufficient batch consistency from existing sheet suppliers

- Need to deal with multiple suppliers for different materials (PET/PP)

- Difficulty in balancing delivery time and quality consistency for international orders

It was against this backdrop that the customer specifically visited the DESU factory in December 2025 for an on-site inspection.

Why did the customer ultimately choose DESU?

During the two-day factory audit and technical exchange, the customer focused on evaluating the following dimensions:

- Raw material system and formulation control capabilities

- Thermoforming performance (heating window, molding stability)

- Food-grade compliance and export experience

- Reliability of bulk order delivery

We fully demonstrated DESU’s core capabilities in the field of PET/PP thermoforming sheets to the customer, including:

- Years of experience in formula design focused on thermoforming applications

- Stable control of thickness, tolerance, and transparency between batches

- Mature packaging and container loading solutions for export markets

At the concluding meeting, the customer clearly stated:

“DESU is not just a sheet supplier, but a solution-oriented factory that understands our production scenarios.”

This was also the key factor that facilitated the rapid progress of cooperation between the two parties.

Product Solutions | Customized Material Combinations for Thermoformed Trays and Blister Packaging

Overview of the shipped products

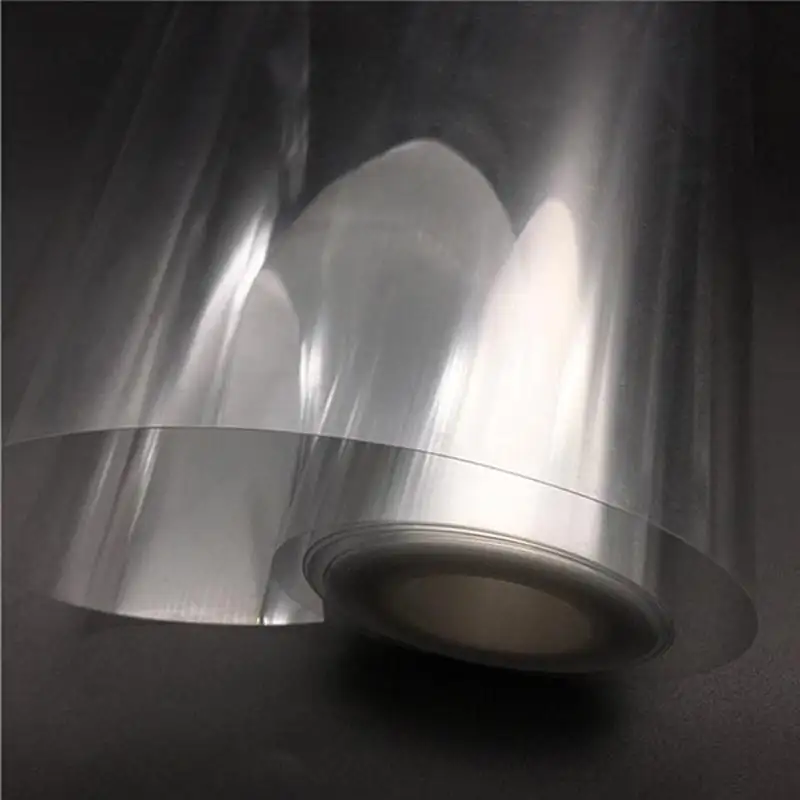

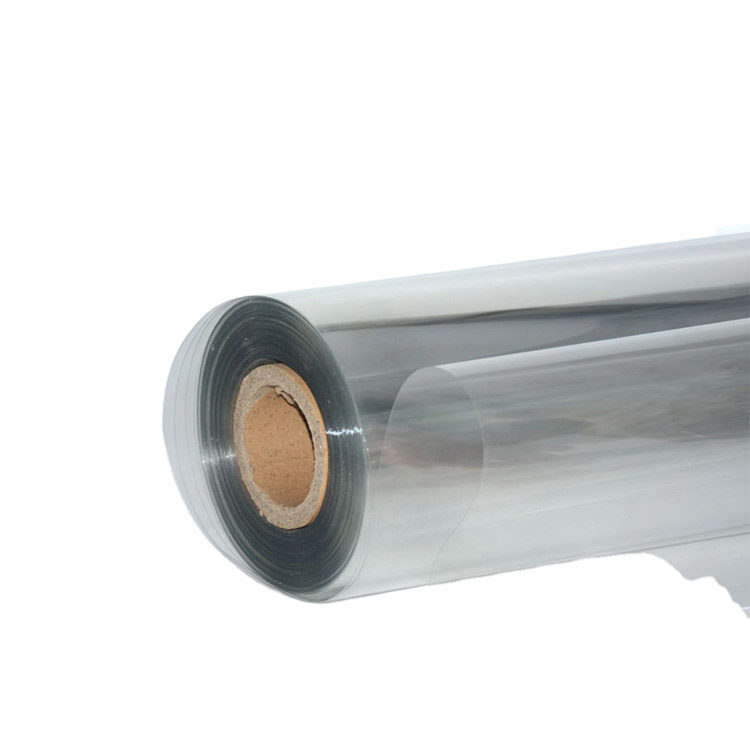

This shipment included a total of 70 tons of sheet rolls, comprising two major product systems:

- PET thermoforming sheet rolls

- PP thermoforming sheet rolls

Mainly used in:

- Food-contact grade thermoformed trays

- Blister packaging for pharmaceuticals and consumer goods

Highlights of the PET sheet solution

To meet the customer’s high requirements for transparency and molding stability, our PET solution features:

- High transparency and low haze, suitable for display packaging

- Wide processing window, adaptable to different heating zone settings

- Good vacuum and pressure molding response

- Supports adjustable rPET content, balancing compliance and cost

This solution demonstrated even corner molding, low rebound rate, and significantly reduced scrap rate during the customer’s trial molding process.

Highlights of the PP sheet solution

For the heat resistance and toughness requirements of food trays, our PP sheet solution offers:

- Stable crystallization control, good dimensional stability after molding

- Suitable for microwave/heat sealing applications

- Excellent stress crack resistance

- Supports continuous supply in multiple thickness ranges

The customer reported that smooth switching could be achieved with existing molds, without the need for additional equipment modifications.

Procurement Decision Perspective | Why This Was a “70-Ton Worthy” Collaboration

From a procurement decision perspective, this collaboration offered several clear value points:

Single Supplier, Covering Multiple Material Systems

DESU consistently supplies both PET and PP thermoforming sheets, helping customers:

- Simplify supply chain management

- Reduce quality risks across multiple suppliers

- Improve the efficiency of annual procurement negotiations

Clear Quality Responsibility Boundaries

At the beginning of the project, DESU confirmed with the customer:

- Molding performance evaluation standards

- Batch consistency indicators

- Division of responsibilities for export and arrival risks

This made it easier for the customer to obtain both technical and financial approval during internal procurement reviews.

Long-Term Supply Capacity Assessment

The customer was not just making a decision for a single order, but was incorporating DESU into their:

- Annual supplier reserve system

- Material cooperation list for future expansion projects

The 70-ton order was a beginning, and also a “testing and scaling up in parallel” milestone.

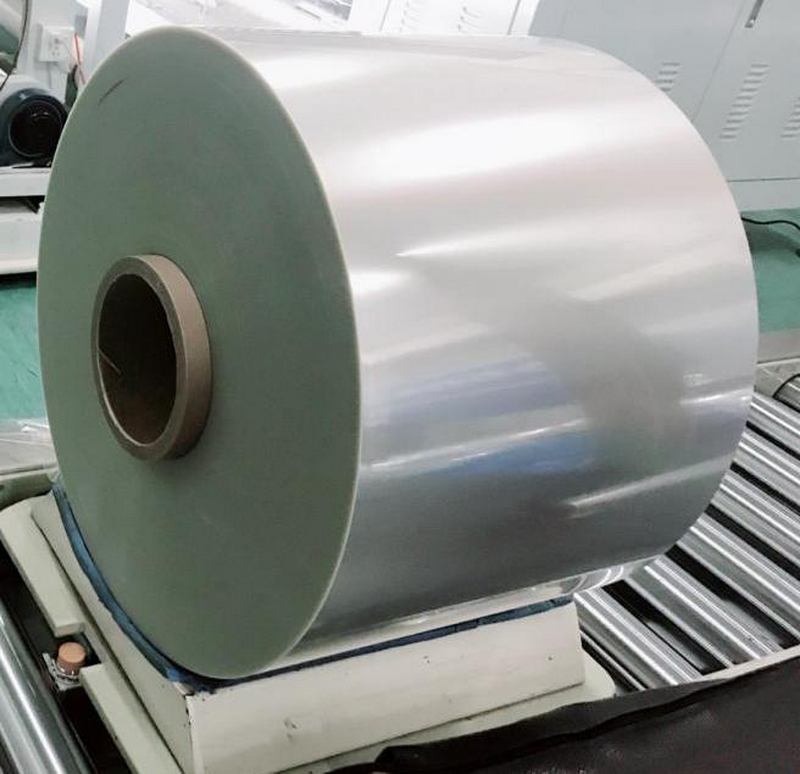

Shipment Execution | Stable Delivery from Production to the Port of Mali

During the production and shipment phase, the DESU team strictly followed export standards:

- Moisture-proof and pressure-resistant packaging for rolls

- Palletized loading, suitable for long-distance sea transport

- Clear batch identification for easy traceability at the factory

The entire shipment process was completed on schedule, with container loading and documentation passing inspection on the first attempt, laying the foundation for subsequent continuous orders.

Future Outlook | From First Collaboration to Long-Term Partnership

This 70-ton shipment of PET & PP sheets to Mali represents more than just a successful delivery; it also signifies:

- Further validation of DESU’s thermoforming sheet solutions in the African market

- The customer’s recognition of DESU’s factory capabilities and professionalism

- Broad opportunities for both parties in future annual framework cooperation, material upgrades, and rPET applications

We anticipate that in the next phase of cooperation, both parties will focus on:

- Higher proportion of environmentally friendly material solutions

- Material support for new molds and new packaging structures

- Stable monthly/quarterly supply plans

And engage in deeper collaboration.

Conclusion

At DESU, we always believe that:

Good thermoforming sheets are not just about meeting parameters, but about truly performing on the customer’s production lines.

This 70-ton order shipped to Mali is a testament to the quality of our products, our team, and our philosophy.

In the future, DESU will continue to provide global thermoforming packaging customers with scalable, repeatable, and long-term material solutions.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM