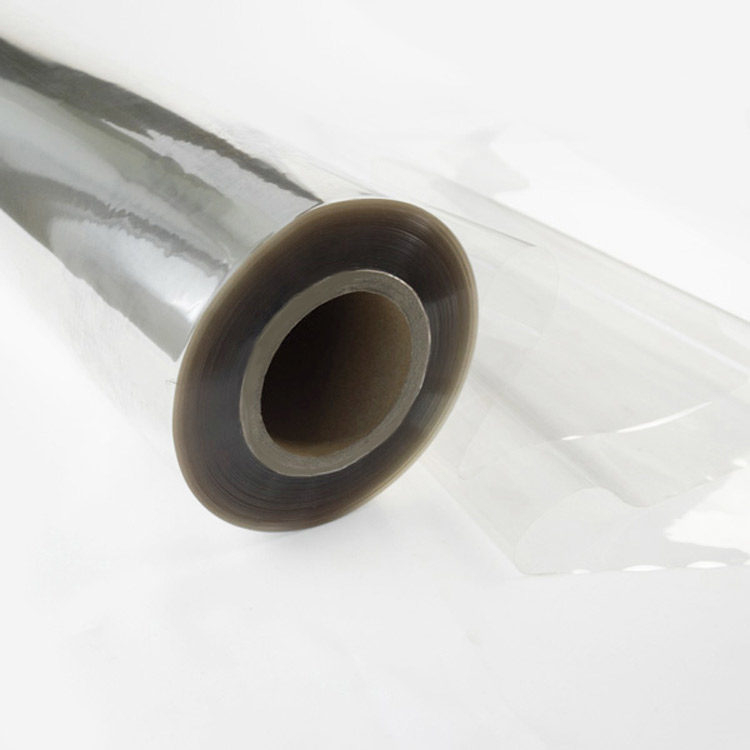

Are You Worried That the PET Plastic Sheet Rolls You Purchase Have Inconsistent Thickness or Uneven Surfaces?

In the fast-growing packaging industry, the quality and consistency of PET plastic sheet rolls can make or break your production efficiency. Many packaging manufacturers face the same frustrating challenges: inconsistent sheet thickness, uneven surface textures, and unstable material performance during thermoforming. These issues not only increase production waste but also compromise the visual appearance and structural strength of the final packaging.

That’s why choosing a reliable and professional PET plastic sheet rolls manufacturer is more important than ever.

The Common Challenges in PET Sheet ROlls Procurement

Many buyers have encountered similar situations:

- Received PET plastic rolls exhibit uneven thickness, resulting in poor molding quality.

- Undesirable ripples, dark spots, or impurities appear on the sheet surface.

- Material clarity and gloss are lower than expected, impacting the product’s shelf appeal.

- Inconsistent molding temperatures and performance across batches from the same supplier.

These quality issues can lead to machine downtime, increased scrap rates, and unnecessary material loss. For companies that rely on precision and consistency, an unreliable PET plastic sheet rolls supply can directly impact profitability and reputation.

The Solution: Partner with a Reliable PET Sheet Manufacturer

This is where Desu (PET-sheet.com) comes in.

As a leading manufacturer of PET plastic sheet rolls in China, Desu has built a solid reputation for precision, consistency, and reliability. With advanced production lines, strict quality control systems, and years of industry experience, Desu provides packaging manufacturers worldwide with high-quality, smooth, and consistent PET sheet rolls that perform exceptionally in blister packaging and thermoforming applications.

About Desu (PET-sheet)

Desu is a factory-qualified company specializing in manufacturing PET, HIPS, and PP plastic sheet rolls. The company operates modern production facilities in Shanghai and Hong Kong, equipped with advanced extrusion technology and automated monitoring systems.

By integrating R&D, production, and export services, Desu ensures that every roll of PET sheet roll meets international standards and customer expectations. The company’s mission is simple yet powerful:

“To provide high-quality, consistent, and sustainable plastic sheet materials for global packaging applications.”

Why Choose Desu(pet-sheet) PET Plastic Sheet Rolls?

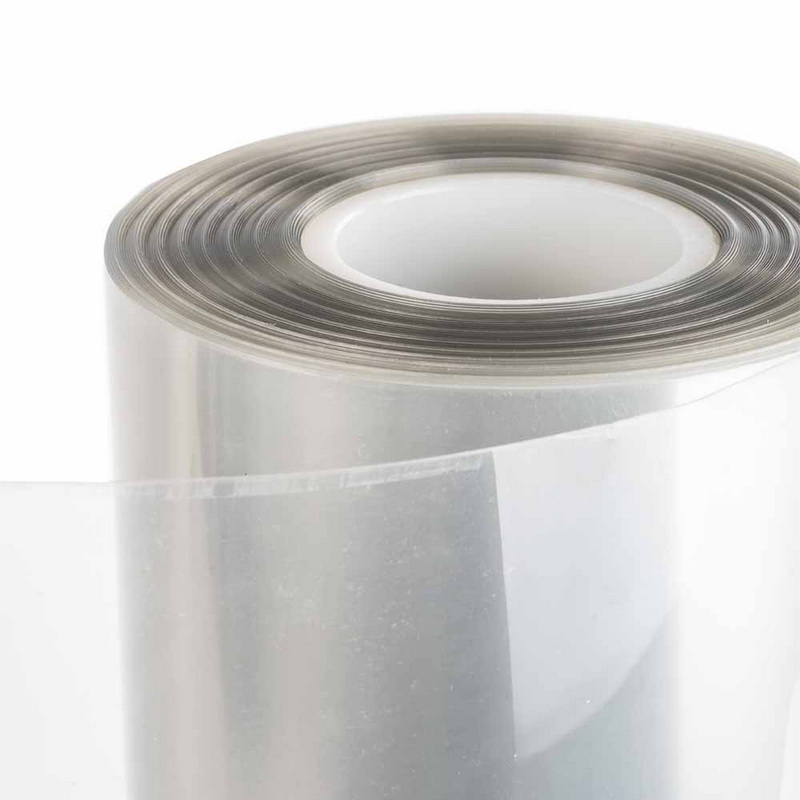

1. Superior Thickness Control

Desu(pet-sheet) uses advanced extrusion technology and precision gauges to maintain strict tolerance control across every roll. The thickness remains stable from beginning to end, ensuring smooth thermoforming without defects or waste.

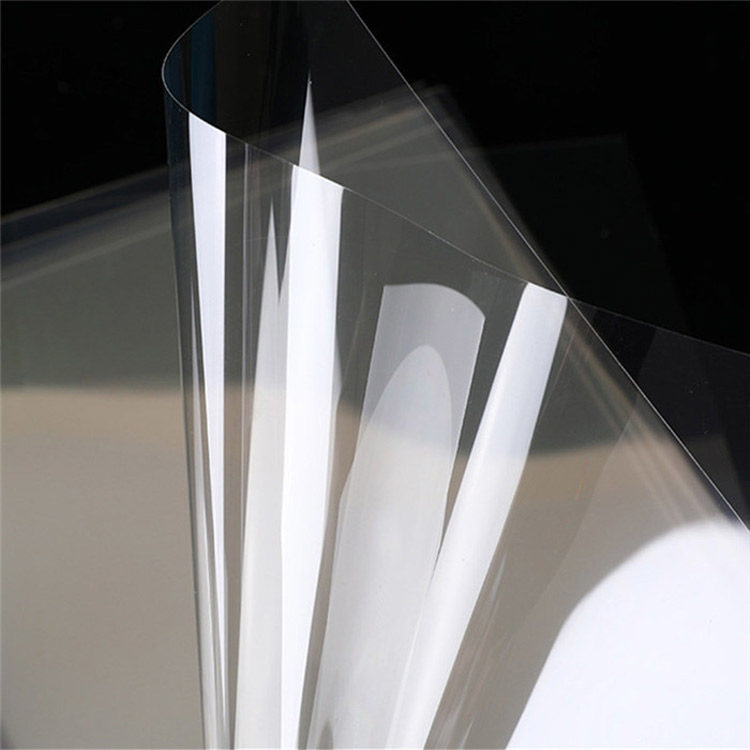

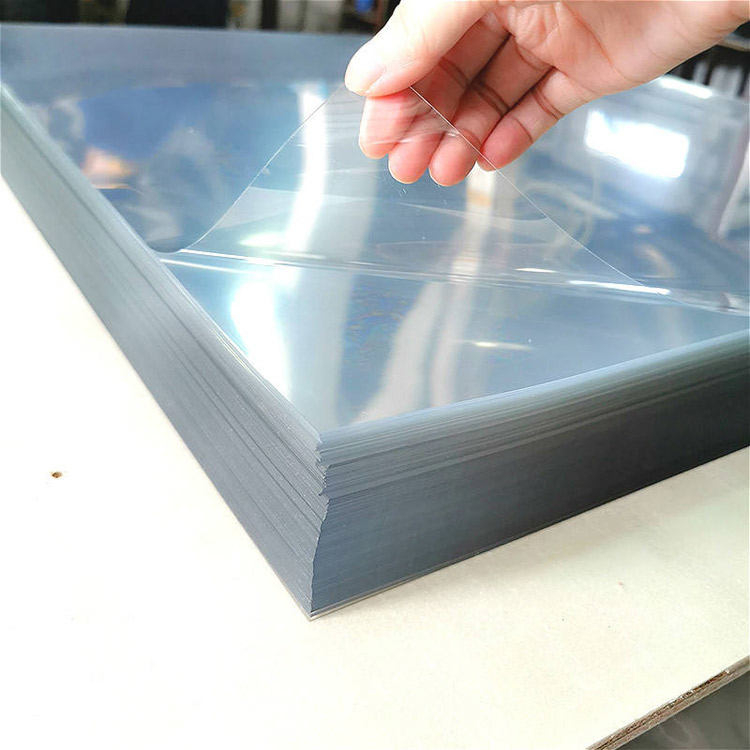

2. Excellent Surface Flatness and Transparency

Each PET roll features a flawless, glossy surface with high transparency, perfect for blister packaging and food trays that require an elegant, clear appearance.

3. 100% Virgin Raw Materials

Desu’s PET sheets are produced using only virgin-grade raw materials, ensuring consistent color, strength, and chemical stability. Recycled or mixed materials are never used for food-grade products.

4. Food-Grade and Eco-Friendly

Complying with FDA, RoHS, and REACH standards, Desu PET sheets are safe for direct food contact and 100% recyclable, supporting sustainable packaging goals.

5. Stable Supply and Fast Delivery

With multiple production lines and a professional logistics team, Desu ensures on-time delivery even during peak seasons. Customers can count on a stable and continuous material supply.

6. Customizable Specifications

Desu offers PET sheet rolls in a wide range of thicknesses (0.2mm–2.0mm), widths (up to 1300mm), and finishes (glossy, matte, anti-static). Custom color options are also available upon request.

Applications of Desu(pet-sheet) PET Plastic Rolls

Desu’s PET plastic sheet rolls are widely used for:

1. Blister Packaging: electronics, cosmetics, hardware tools, and consumer goods.

2. Food Packaging: fruit trays, bakery containers, beverage lids, and disposable food boxes.

3. Medical and Pharmaceutical Packaging: blister packs for tablets and sterile medical devices.

4. Industrial Applications: folding boxes, clamshell packaging, and vacuum forming components.

Regardless of the industry, Desu’s PET plastic rolls offer the clarity, strength, and consistency required to maintain product quality and enhance brand presentation.

Customer-Focused Service

Beyond production, Desu provides comprehensive customer support, including:

1. Technical guidance for thermoforming and product design.

2. Fast response to inquiries and customized order requirements.

3. Reliable export documentation and logistics coordination.

Desu believes that strong partnerships are built on trust, communication, and continuous improvement.If you are tired of receiving PET plastic sheet rolls with inconsistent thickness, uneven surfaces, or poor forming quality, it’s time to switch to a supplier who truly understands your needs.

Desu (pet-sheet.com) is your dependable partner for high-quality, precision-engineered PET sheet rolls. With professional manufacturing capabilities, strict quality management, and customer-oriented service, Desu helps global packaging companies achieve stable production, reduced waste, and superior packaging results.

to learn more or request a quotation today. Discover how Desu can help you achieve packaging excellence with reliability and precision.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM