How to choose between internal conductive PET rolls and surface coated conductive PET rolls?

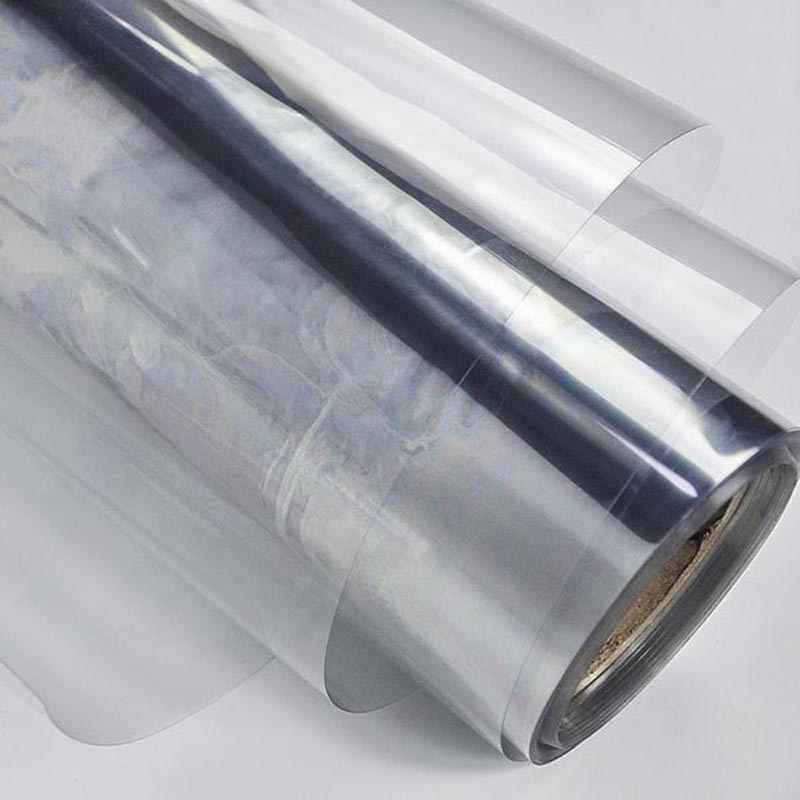

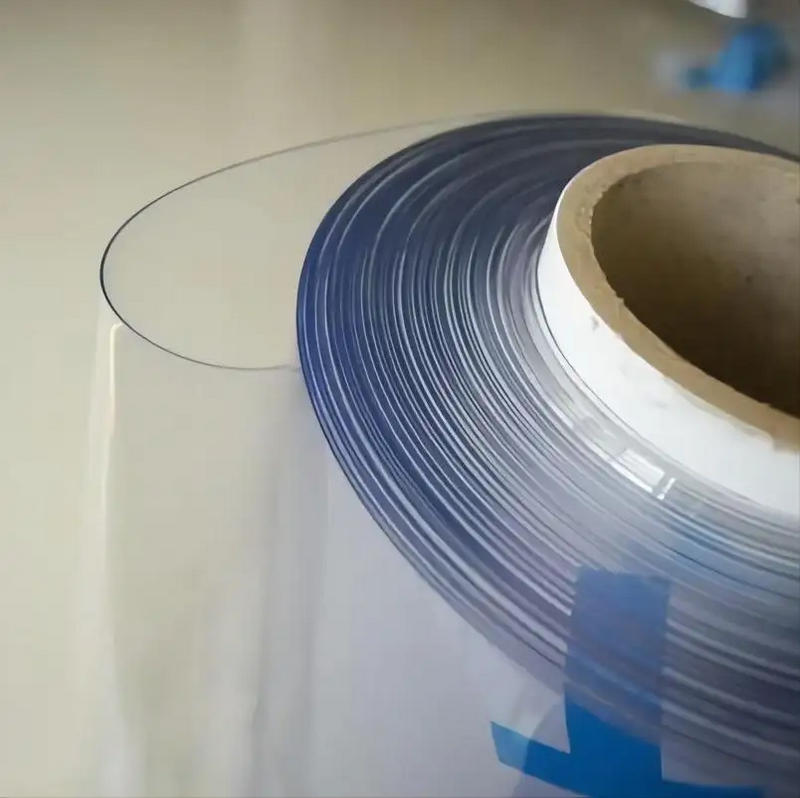

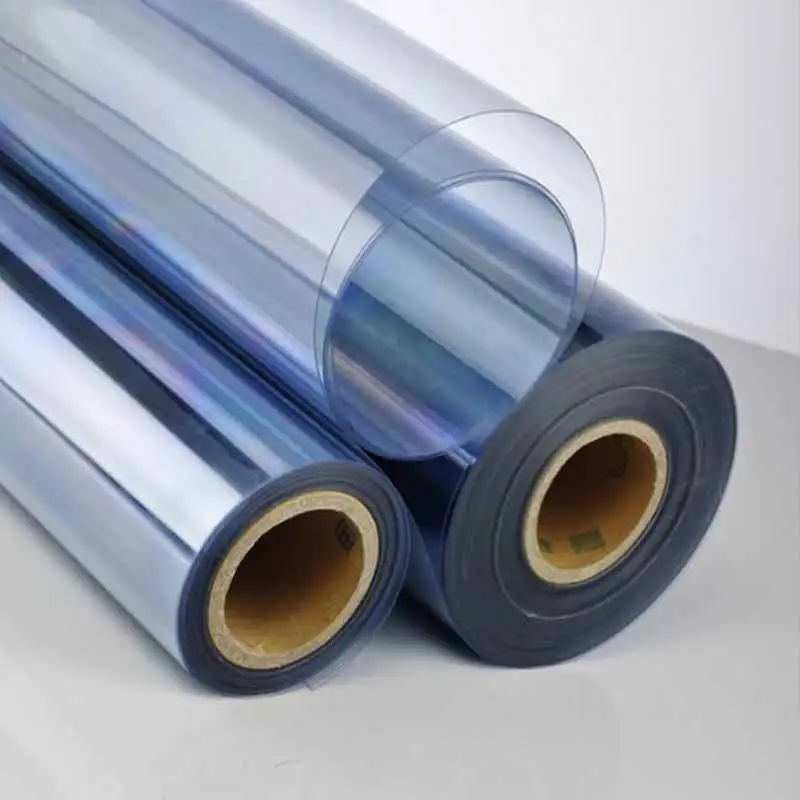

As the demand for high-performance materials increases across various industries, selecting the right type of conductive PET (Polyethylene Terephthalate) rolls has become a critical decision for manufacturers. The two primary options available are internal conductive PET rolls and surface-coated conductive PET rolls. Both types offer unique advantages, and the choice depends on the specific application and performance requirements.

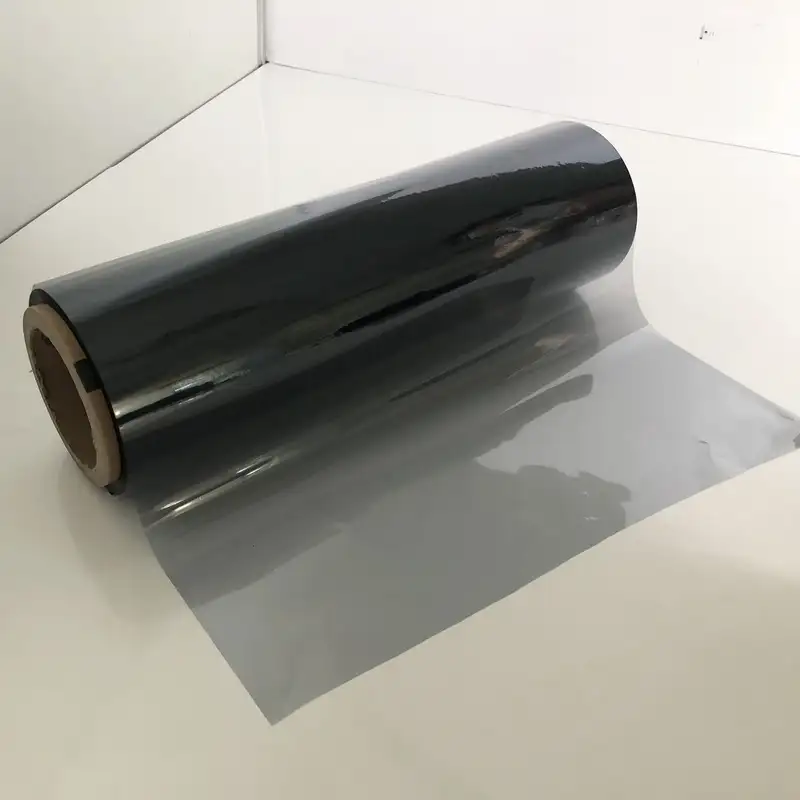

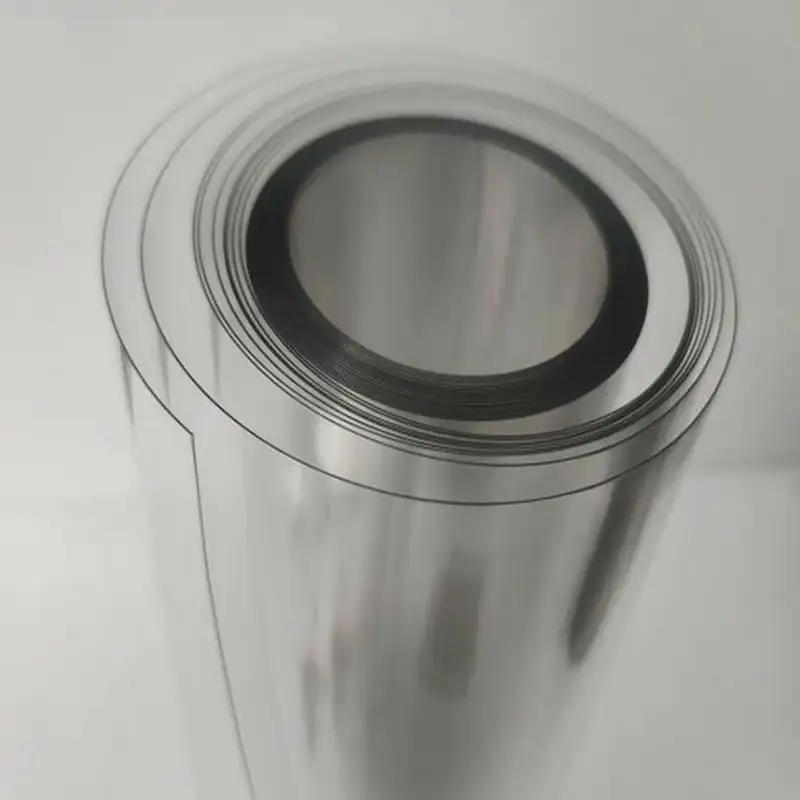

Internal Conductive PET Rolls: A Deeper Integration of Conductivity

Internal conductive PET rolls are manufactured with conductive materials embedded throughout the PET substrate, ensuring conductivity is maintained across the entire thickness of the material. This type of PET roll is ideal for applications requiring uniform conductivity throughout, such as in static-sensitive environments or certain types of shielding.

Key Benefits

- Consistent conductivity: Provides uniform electrical conductivity throughout the material, ideal for shielding and antistatic purposes.

- Durability: The conductivity is integrated into the PET structure, making it resistant to wear and environmental stress.

- Longevity: Since the conductivity is inherent to the material, there is no risk of it wearing off over time.

Applications

- Electronics packaging

- Static control in manufacturing processes packaging

- Sensitive equipment shielding packaging

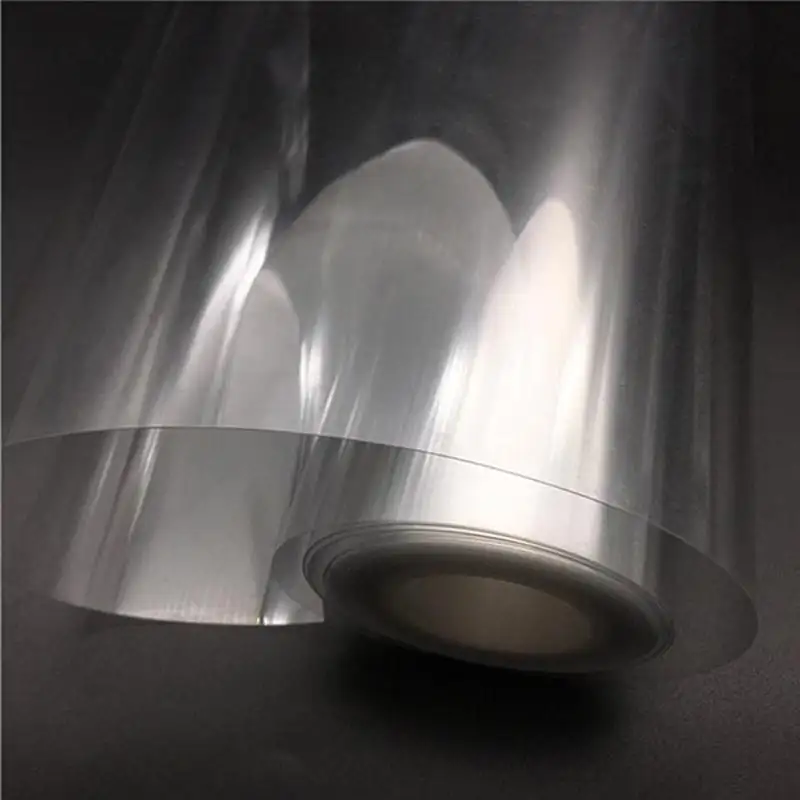

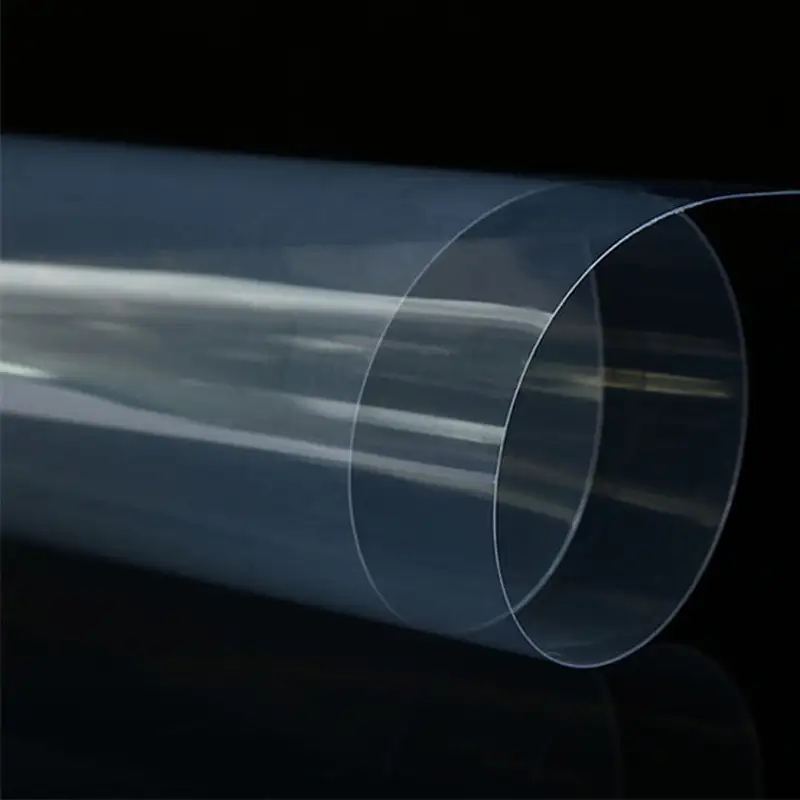

Surface Coated Conductive PET Rolls: Flexible and Cost-Effective

Surface-coated conductive PET rolls, on the other hand, feature a conductive layer applied to the surface of the PET substrate. This coating provides a conductive surface, which is often more cost-effective compared to internal conductive solutions.

Key Benefits

- Cost-effective: The surface coating process is less expensive, making it a more economical choice for applications with less stringent conductivity requirements.

- Customizable: The thickness and properties of the conductive coating can be adjusted based on specific needs.

- Flexibility: Ideal for applications where only the surface needs to be conductive.

Applications

- Temporary electrostatic discharge (ESD) protection packaging

- Display screens packaging

- Packaging materials for low-risk static environments

Making the Right Choice

When deciding between internal conductive PET rolls and surface-coated conductive PET rolls, it’s important to consider the following factors:

1. Performance Requirements: If you need long-term, reliable conductivity, internal conductive PET rolls are likely the better option. For less demanding applications, surface-coated rolls may suffice.

2. Cost Considerations: Surface-coated PET rolls are typically less expensive, but the additional longevity and durability of internal conductive PET rolls might justify the extra cost in certain applications.

3. Application-Specific Needs: The intended use (e.g., packaging, shielding, or ESD protection) plays a significant role in the decision. Understanding how the PET rolls will be used will help determine which product offers the best value.

Both internal conductive PET rolls and surface-coated conductive PET rolls have their own set of advantages. The key to making the right decision lies in understanding the specific needs of your application, including factors such as cost, durability, and performance. By carefully evaluating these aspects, you can select the conductive PET solution that best meets your requirements.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM