How to Choose PET Plastic Rolls?

Introduction

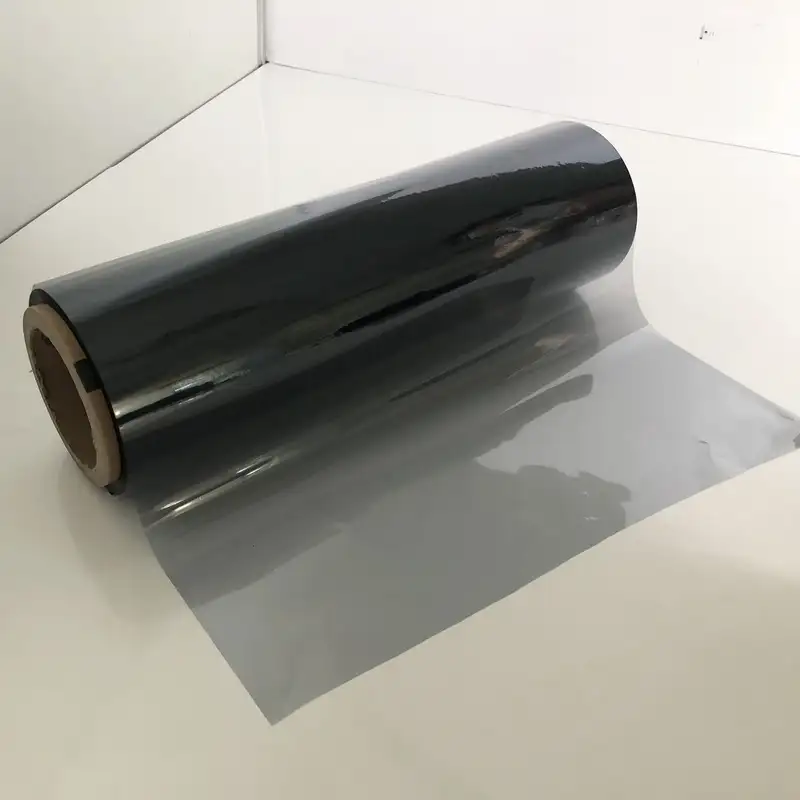

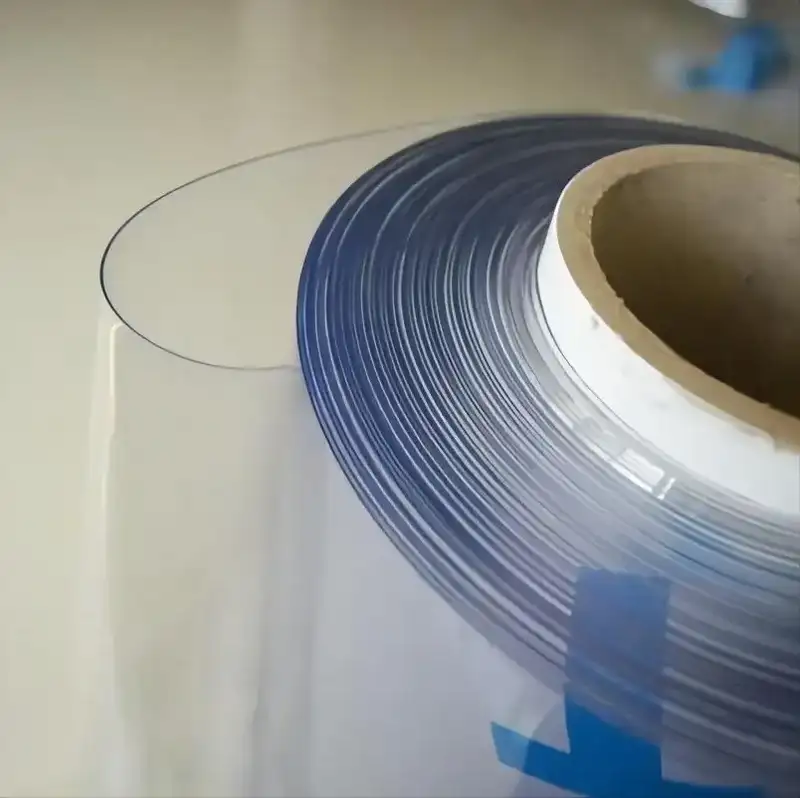

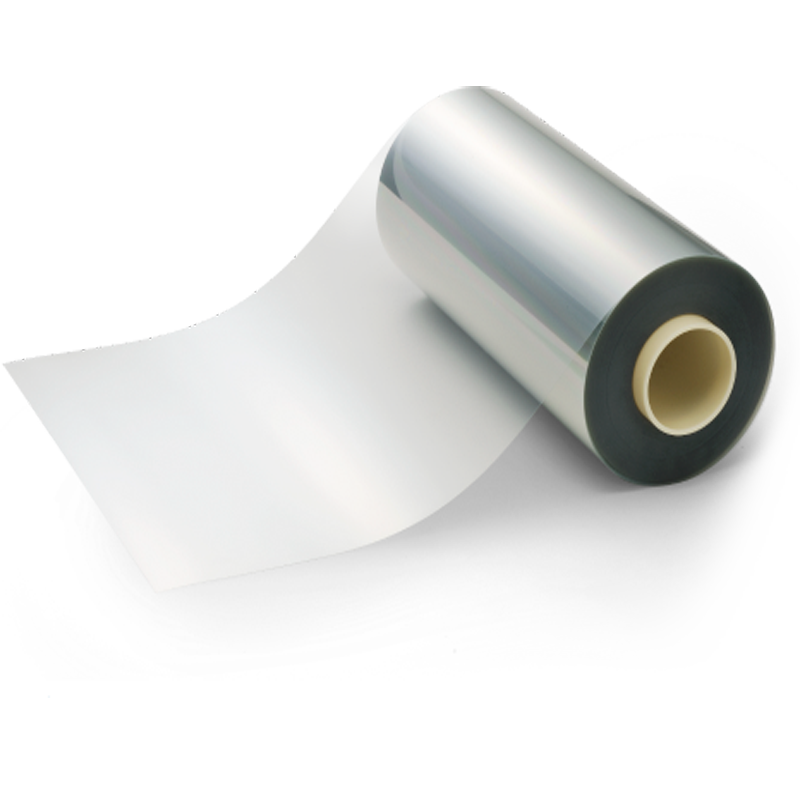

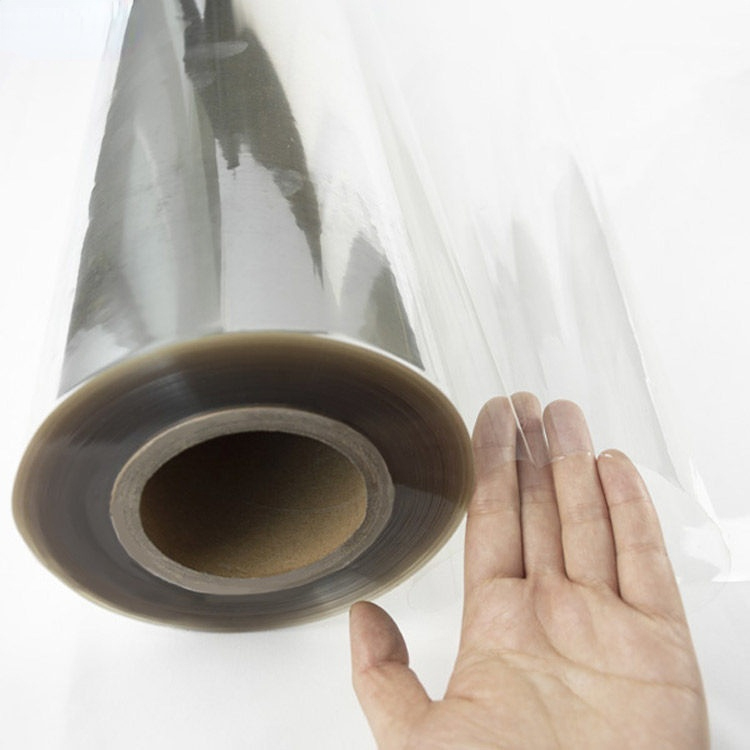

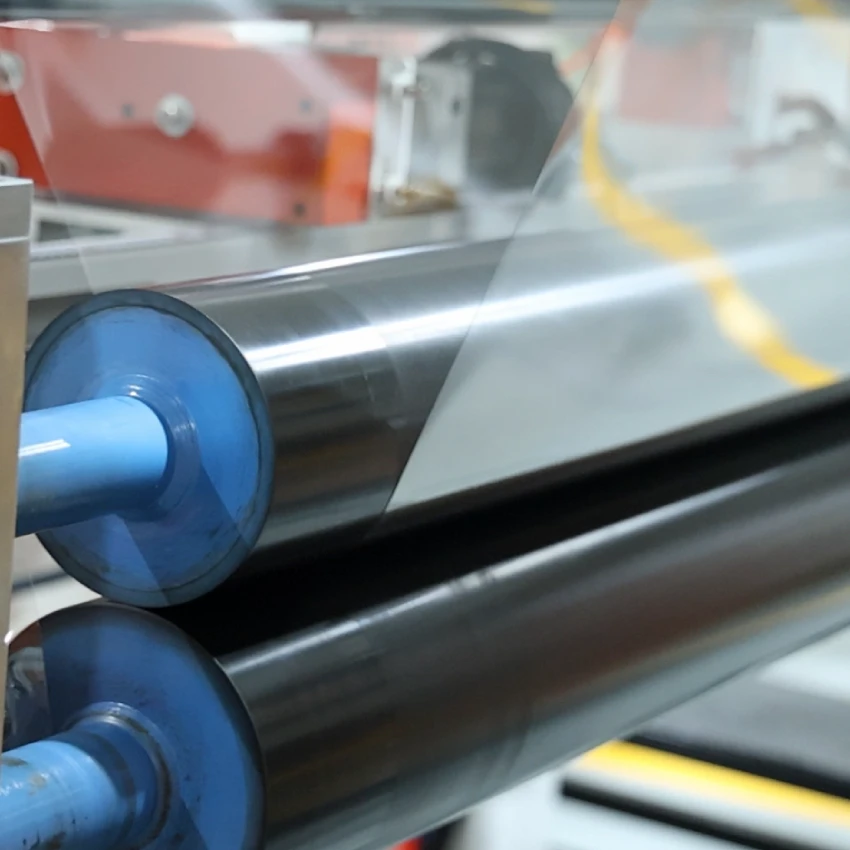

PET (Polyethylene Terephthalate) plastic rolls are widely used in industrial packaging, food trays, blister packaging, and thermoforming applications.

For B2B buyers such as food packaging manufacturers, distributors, and industrial product companies, selecting the right PET plastic rolls is critical for product quality, operational efficiency, and regulatory compliance.

This guide provides practical advice for B2B procurement teams on evaluating, sourcing, and purchasing PET plastic rolls.

Understanding PET Plastic Rolls

PET plastic rolls are available in various grades and specifications. Key characteristics to consider include:

1. Material Grade: Food-grade PET vs general industrial PET. Food-grade PET is certified for direct contact with food and meets FDA, EU, or local food safety standards.

2. Thickness: Common thicknesses include 0.2–2.0 mm. Thickness affects thermoforming performance, rigidity, and cost.

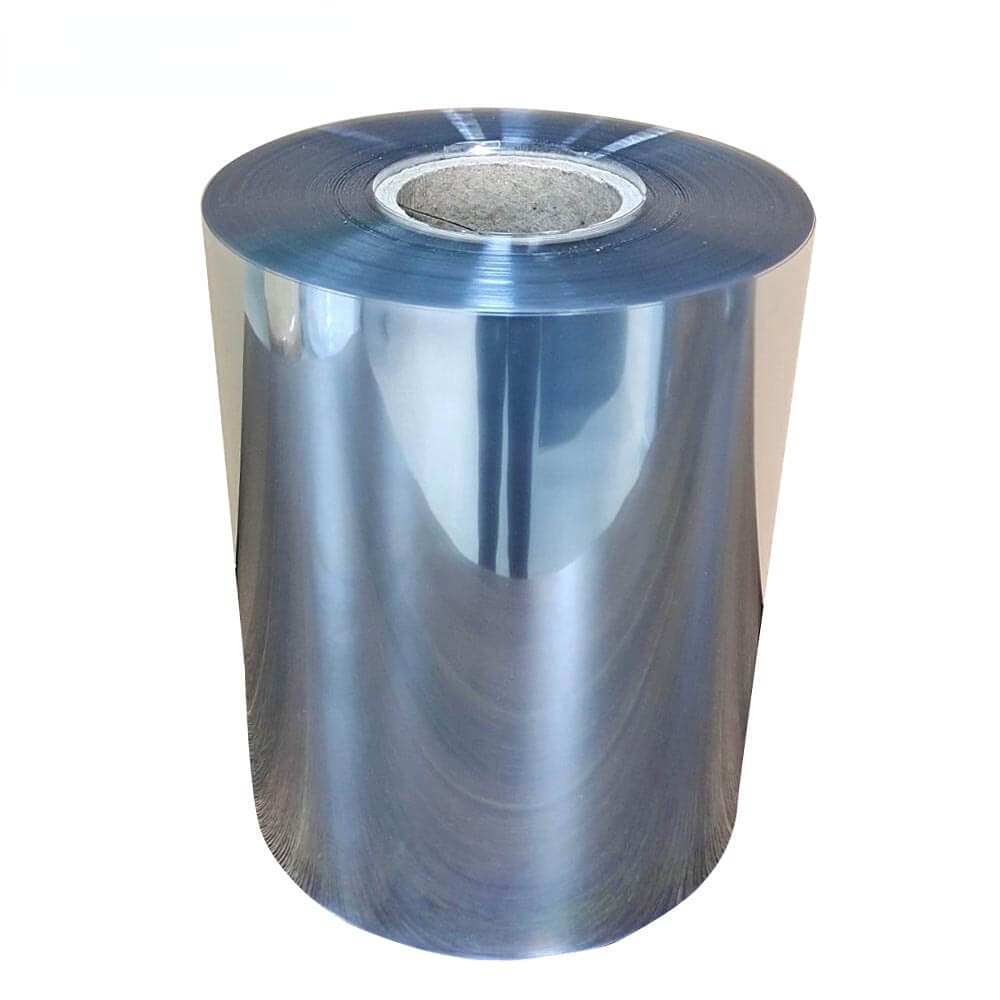

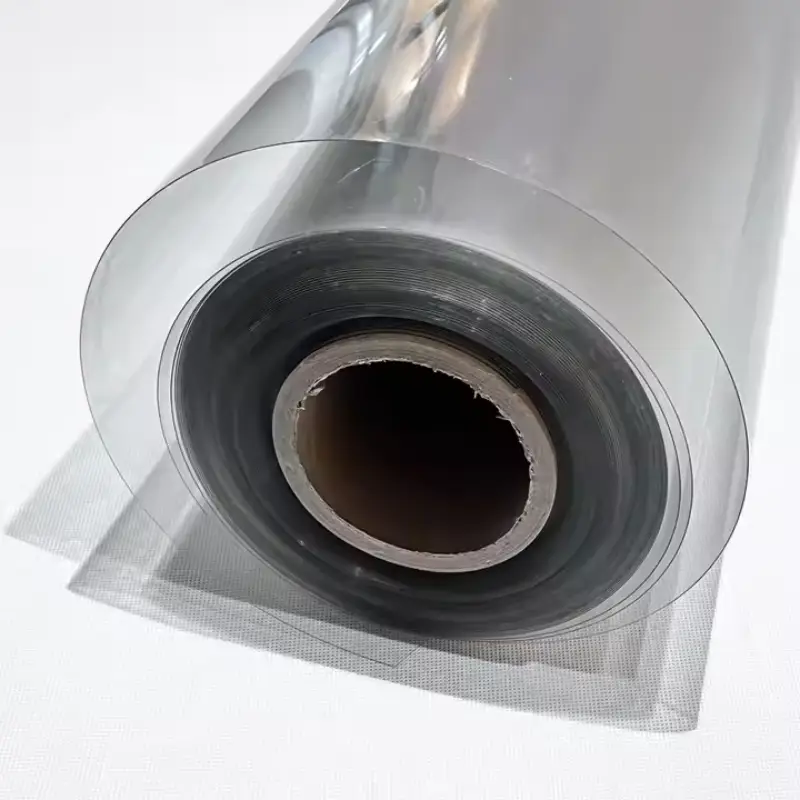

3. Transparency & Gloss: High clarity and gloss enhance product presentation, important for retail packaging.

4. Heat Resistance: PET with high heat resistance ensures stability during thermoforming and filling operations.

5. Width & Roll Length: Standard roll widths range from 300 mm to 1400mm; roll length is typically customized to match production lines.

Key Considerations for B2B Buyers

When selecting PET plastic rolls, B2B buyers should evaluate:

| Feature | What to Check |

|---|---|

| Material Source | 100% virgin PET is preferred for consistency and quality. |

| Thickness Tolerance | Tight tolerance ensures uniform thermoforming and reduces material waste. |

| Batch Consistency | Consistent rolls in color, clarity, and mechanical properties are critical for large-scale production. |

| Thermoforming Performance | Confirm the PET sheet performs well under your specific thermoforming process. |

| Certifications | FDA, EU, ISO 9001, ISO 22000, or local food contact certifications. |

| Moisture & Anti-static Properties | Important for maintaining product quality during processing and storage. |

Supplier Evaluation Checklist

Selecting a reliable supplier is as important as choosing the right material. Consider:

1. Production Capacity: Can the supplier handle large or repeated orders without supply delays?

2. Customization Capability: Can they provide custom thickness, width, and roll lengths to suit your production line?

3. Quality Assurance: Do they perform batch testing and provide certificates of analysis?

4. Experience with Industrial Clients: A supplier familiar with B2B applications understands your operational requirements.

5. Logistics & Delivery: Stable supply chain and timely delivery minimize production interruptions.

Cost & Value Considerations

While price is important, B2B buyers should focus on total cost of ownership:

1. Unit Price vs Quality: Low-cost rolls may cause defects or higher waste. Batch Consistency: Poor consistency increases machine downtime and labor costs.

2. Shipping & Storage: Rolls with improper packaging may incur transport damages or additional storage costs.

3. Long-Term Supplier Relationship: Reliable suppliers help reduce procurement risks and improve operational efficiency.

Application-Based Recommendations

Different applications require specific PET characteristics:

1. Food Packaging: High clarity, food-grade certification, heat resistance for hot filling.

2. Blister Packaging: Excellent thermoforming performance, rigidity for product protection.

3. Industrial Parts: Thick PET sheets with high mechanical strength.

4. Retail Displays: High gloss, transparency, and surface finish for visual appeal.

Practical B2B Procurement Tips

1. Request Samples: Always test sample rolls under your production conditions before bulk purchase.

2. Check Certifications: Verify food contact and safety certifications.

3. Inspect Rolls on Delivery: Ensure no scratches, contamination, or defects.

4. Maintain Supplier Communication: Establish long-term relationships for consistent quality and flexible supply.

5. Use a Procurement Checklist: Track key parameters such as thickness, width, batch number, certifications, and supplier contact info.

Test sample rolls before bulk purchase

Verify food contact & safety certifications

Ensure no scratches or defects

Build long-term supplier relationships

Track thickness, width, batch number, certifications

Why choose Desu(pet-sheet) PET Plastic Rolls?

Desu (pet-sheet) is a trusted manufacturer of high-quality PET plastic rolls. We offer:

1. 100% Virgin PET Material: Ensuring consistent quality and food-grade safety.

2. Precision Thickness & Width: Tight tolerances for reliable thermoforming.

3. Batch Consistency: Uniform color, clarity, and mechanical properties across large orders.

4. Custom Solutions: Flexible roll sizes, thickness, and lengths to meet your production needs.

5. Reliable Supply & Support: Stable production capacity and responsive customer service.

Desu PET plastic rolls help customers achieve efficiency, quality, and compliance in industrial and food packaging applications.

Contact Us

For more information, please contact us.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM