Is There A Difference Between PET APET PETG

August 1, 2024

News

there are differences between PET (Polyethylene Terephthalate), APET (Amorphous Polyethylene Terephthalate), and PETG (Polyethylene Terephthalate Glycol), which are variations of the same base polymer, PET. These differences arise from variations in the manufacturing processes and the specific modifications made to the base PET polymer. Here’s a breakdown of the distinctions:

-

PET (Polyethylene Terephthalate):

- General Characteristics: PET is a common thermoplastic polymer widely used for various applications, including packaging, textiles, and containers.

- Processing: It can be processed through injection molding, blow molding, and extrusion.

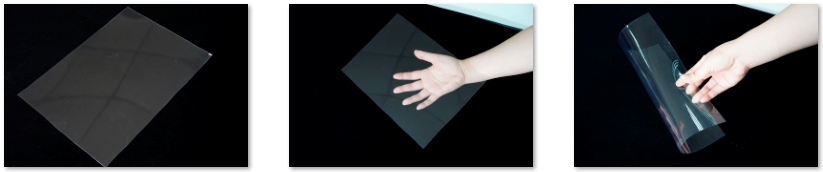

- Properties: PET is transparent, has good mechanical properties, and is widely recyclable.

- Applications: Commonly used in beverage bottles, food packaging, and fiber applications.

-

APET (Amorphous Polyethylene Terephthalate):

- Manufacturing Process: APET is a specific form of PET that undergoes an additional manufacturing process to enhance its transparency and reduce crystallinity, resulting in an amorphous structure.

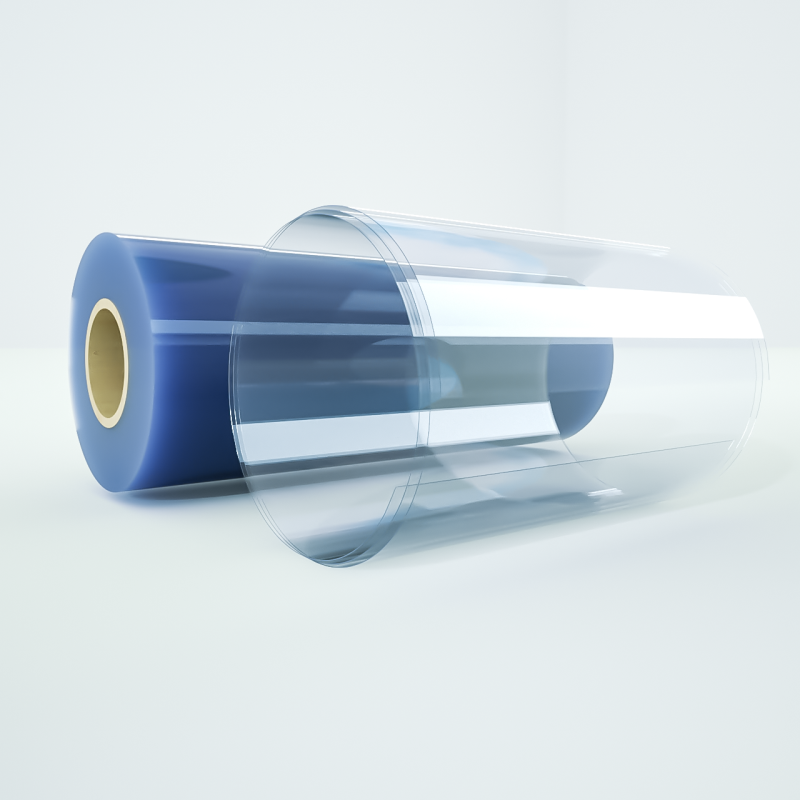

- Properties: APET is characterized by improved clarity and reduced haze compared to regular PET.

- Applications: Commonly used in clear packaging applications, such as thermoformed trays, blister packaging, and transparent containers.

-

PETG (Polyethylene Terephthalate Glycol):

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.

- Main Category

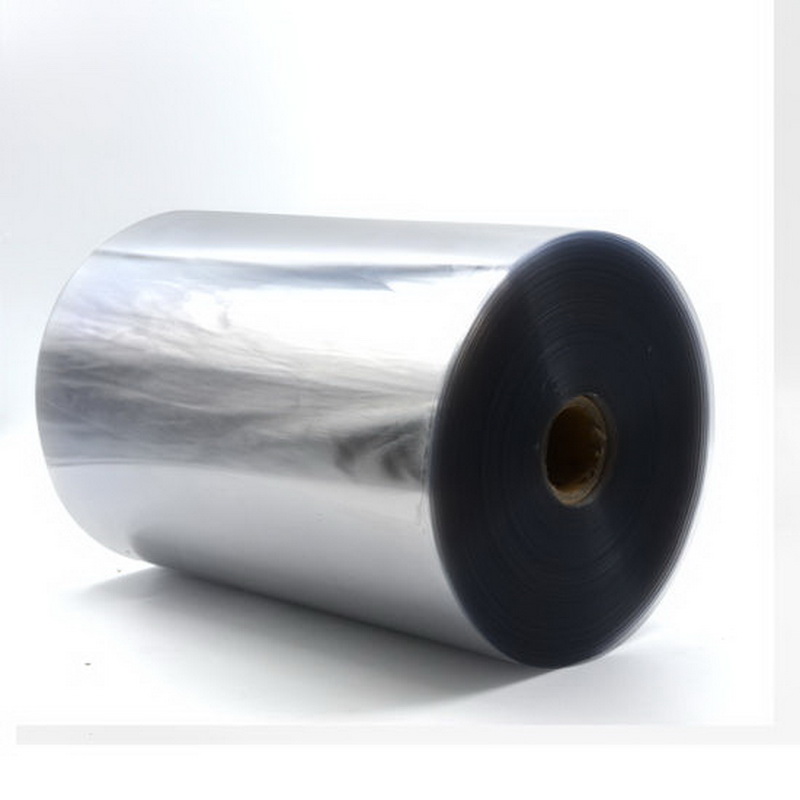

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM