How To Choose The Right Plastic For Your Thermoformed Packaging

Choosing the right plastic for thermoformed packaging is crucial to ensure the packaging meets the specific requirements of your product and application. Several factors should be considered in the selection process:

-

Type of Product:

-

Food Products: If the packaging is intended for food products, it’s essential to choose a plastic material that complies with food safety regulations. Common choices include PET, APET, or PP, which are FDA-approved and suitable for direct food contact.

-

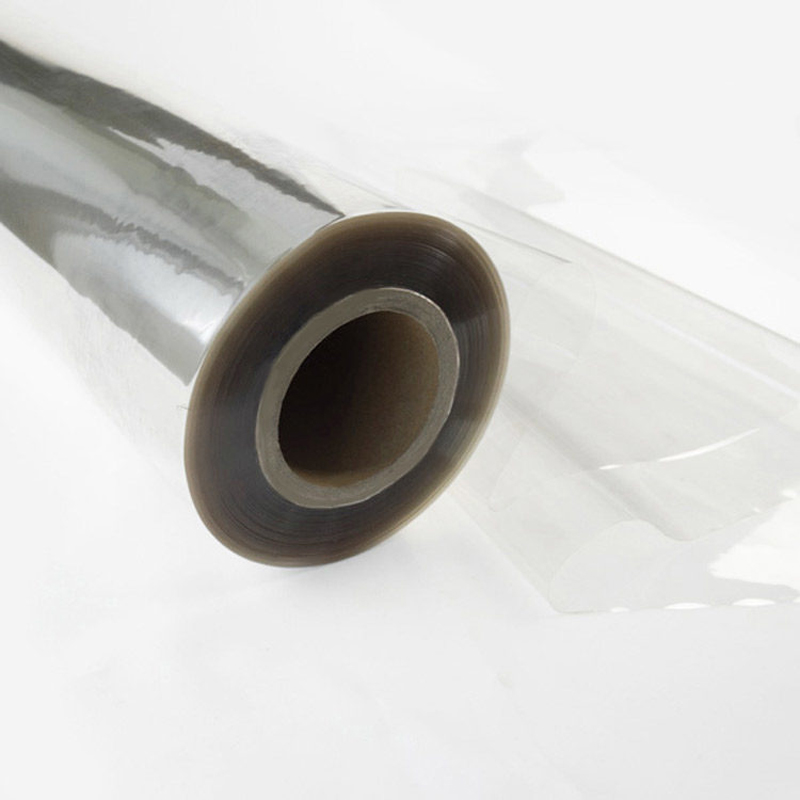

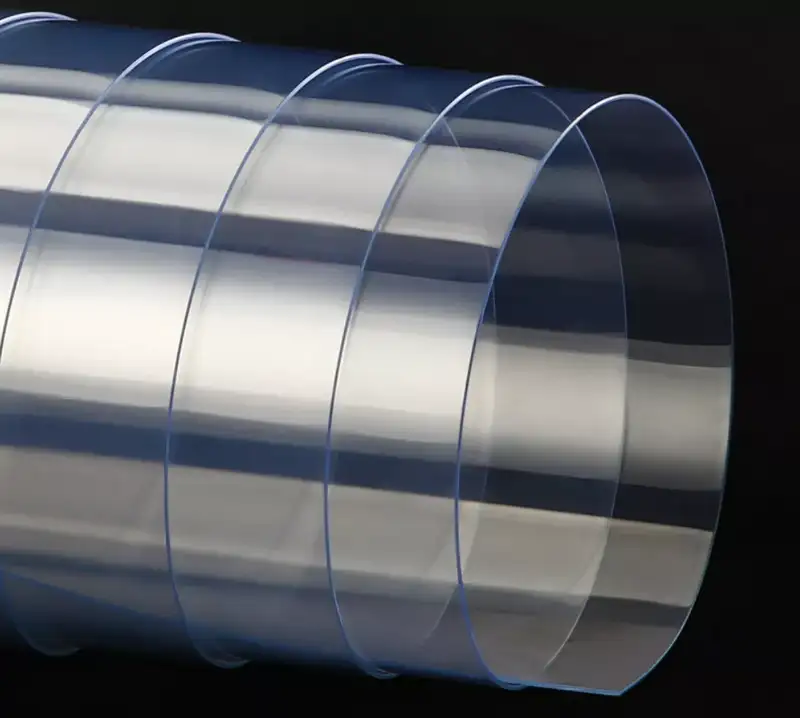

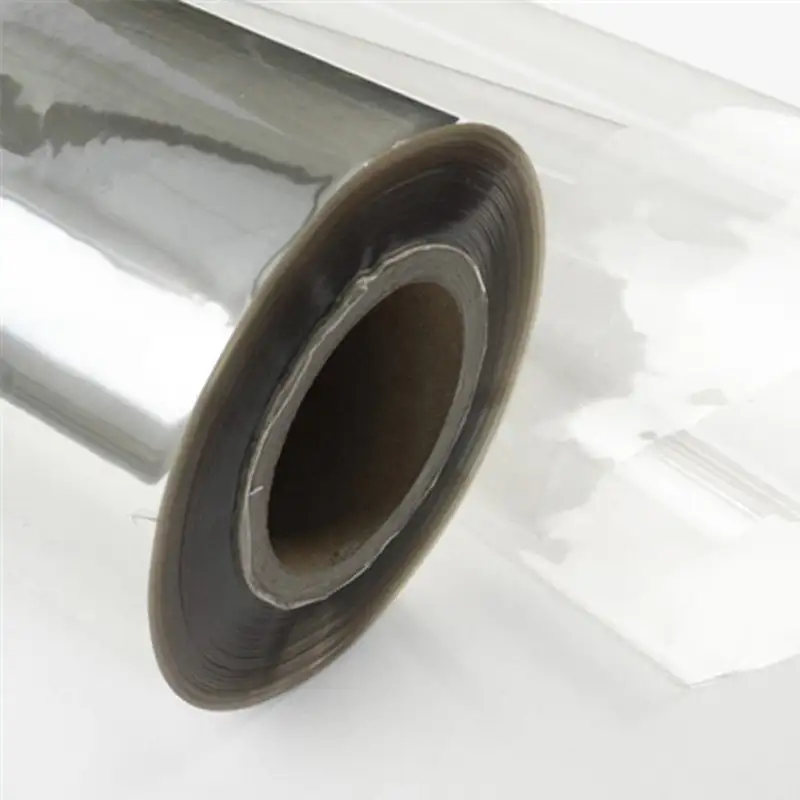

Non-Food Products: For non-food products, consider factors such as the weight, shape, and dimensions of the product. Some plastics, like PVC or PETG, offer good clarity for display purposes.

-

-

Barrier Properties:

-

Moisture Barrier: If your product is sensitive to moisture, choose a plastic with good moisture barrier properties. Materials like PET and PETG provide good moisture resistance.

-

Gas Barrier: Some products, especially those prone to oxidation, may require a plastic with good gas barrier properties. EVOH (Ethylene Vinyl Alcohol) can be added to certain plastics to enhance gas barrier characteristics.

-

-

Clarity and Appearance:

-

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.

-

- Main Category

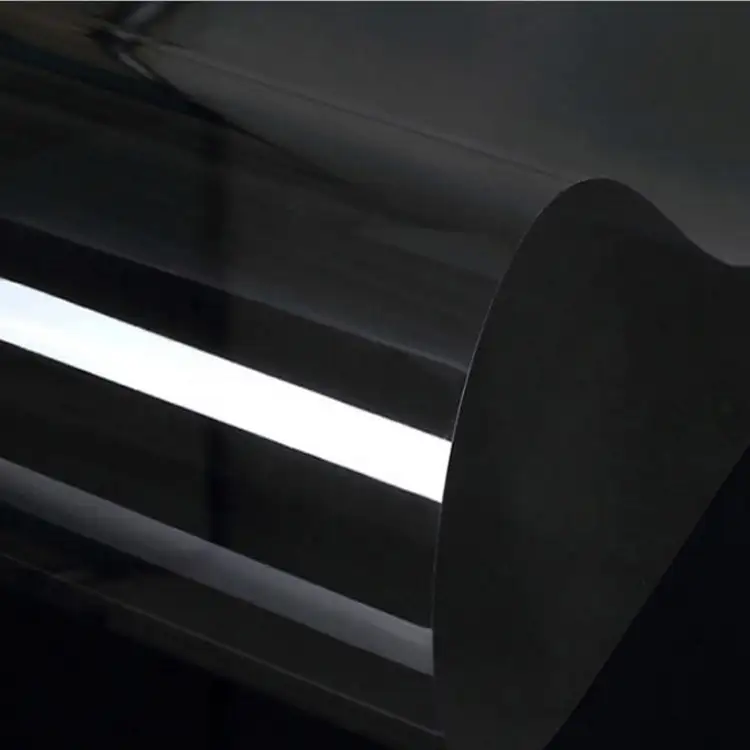

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM