What Are the Advantages of Food Grade PET Plastic Rolls in Modern Food Packaging?

Introduction

In today’s highly competitive food packaging industry, manufacturers are increasingly focused on sourcing materials that ensure product safety, efficiency, and sustainability.

Among the various options available, food grade PET (Polyethylene Terephthalate) plastic rolls have emerged as a preferred choice for modern packaging applications.

Their unique combination of physical properties, regulatory compliance, and production flexibility makes them ideal for a wide range of food packaging requirements.

Understanding Food Grade PET Plastic Rolls

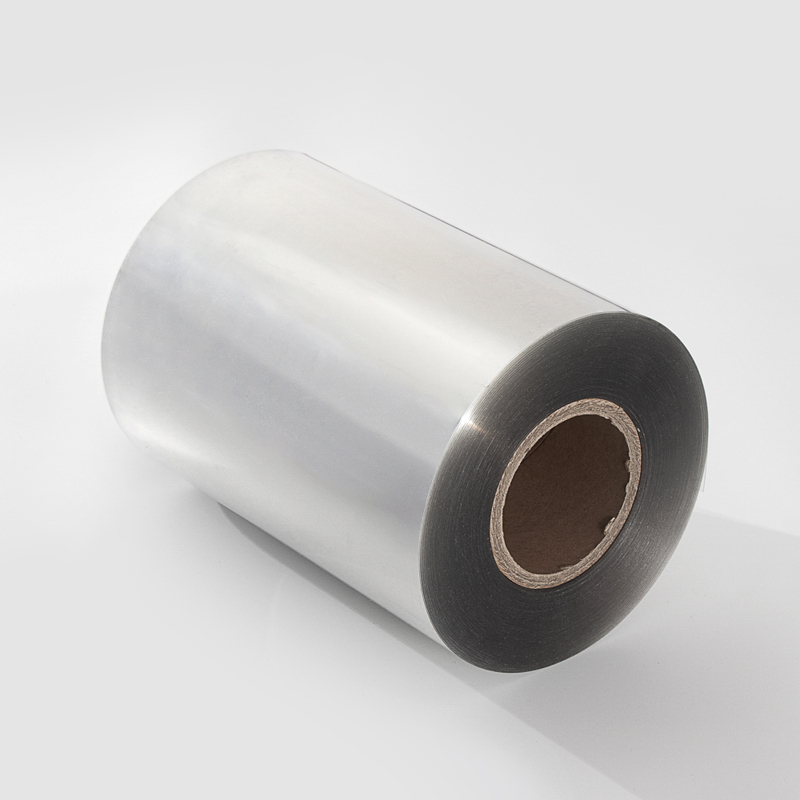

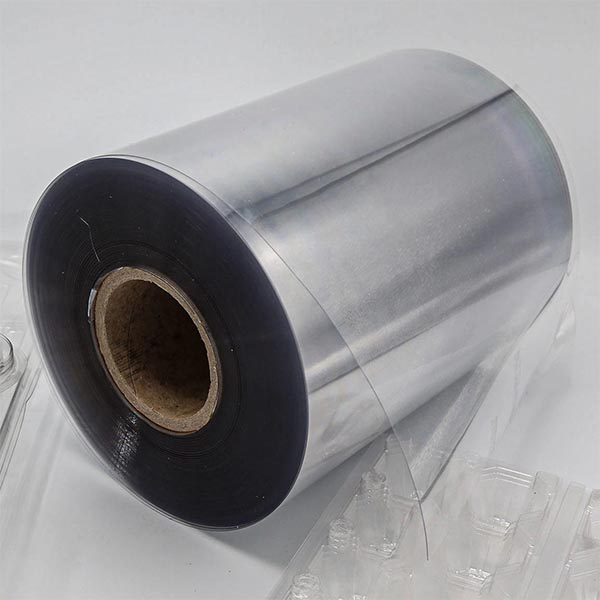

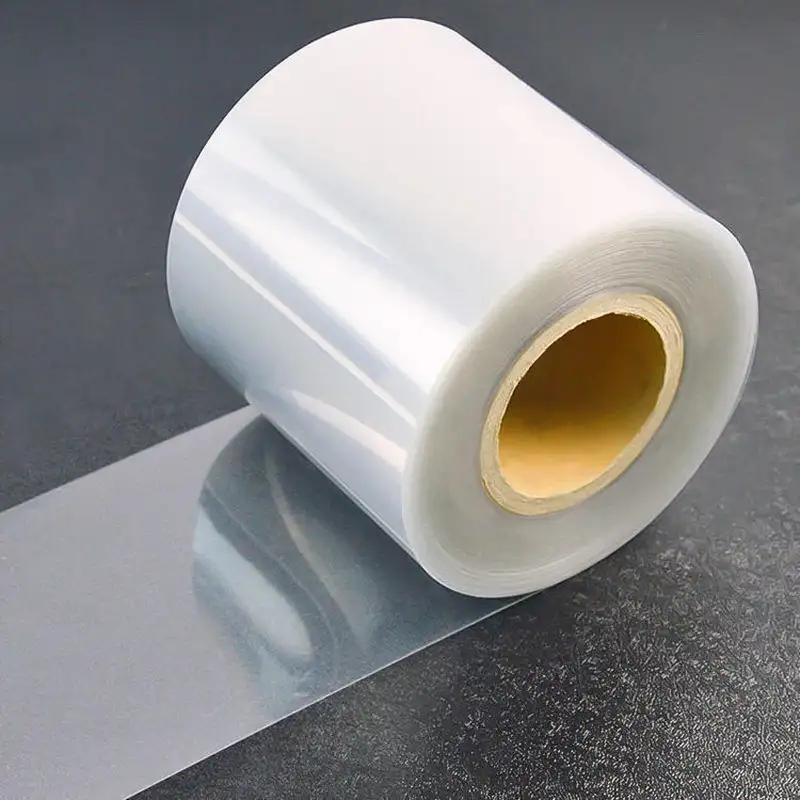

Food grade PET plastic rolls are specialized sheets manufactured from high-purity, virgin PET resin, designed to meet stringent food contact safety standards.

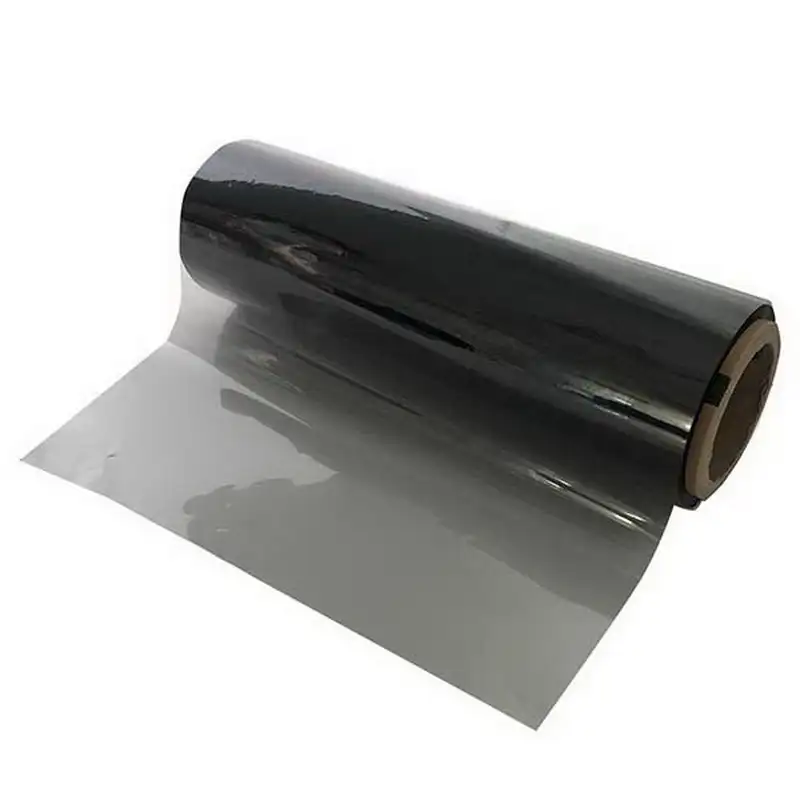

Unlike ordinary PET or other common packaging plastics such as PVC or PS, food grade PET rolls are engineered to prevent contamination, maintain chemical inertness, and preserve the freshness and appearance of food products.

These properties are particularly critical for applications like blister packs, clamshells, trays, and vacuum-formed packaging, where product visibility and hygiene are essential.

Core Advantages of Food Grade PET Plastic Rolls

1.Food Safety and Regulatory Compliance

Food packaging materials must comply with international food contact regulations, including FDA, EU, and other regional standards.

Food grade PET rolls are produced under strict quality control protocols, ensuring they are free from harmful additives or residues. This compliance reduces risk for manufacturers and reassures consumers about product safety.

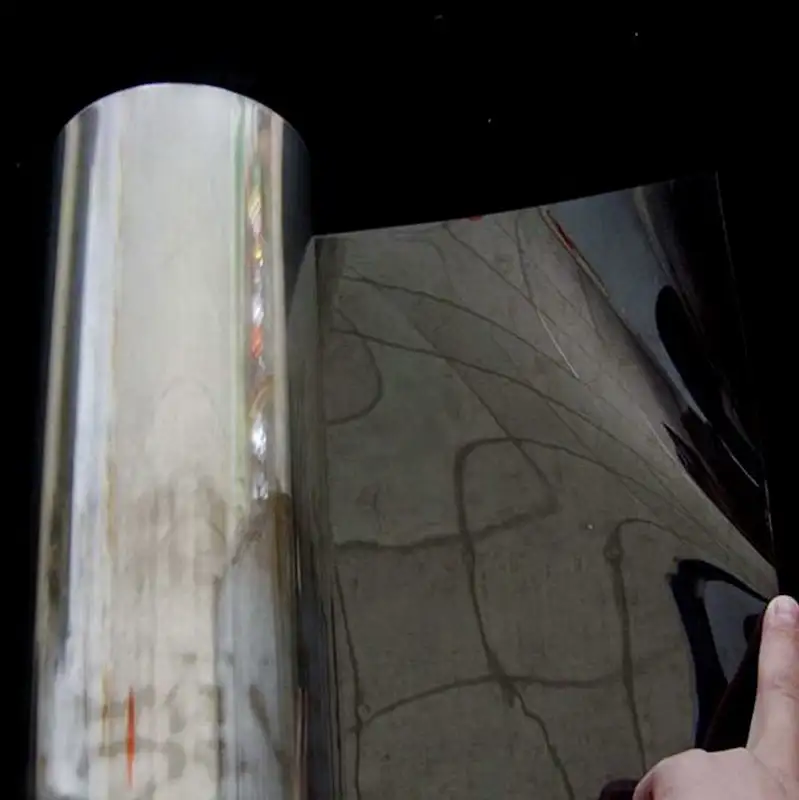

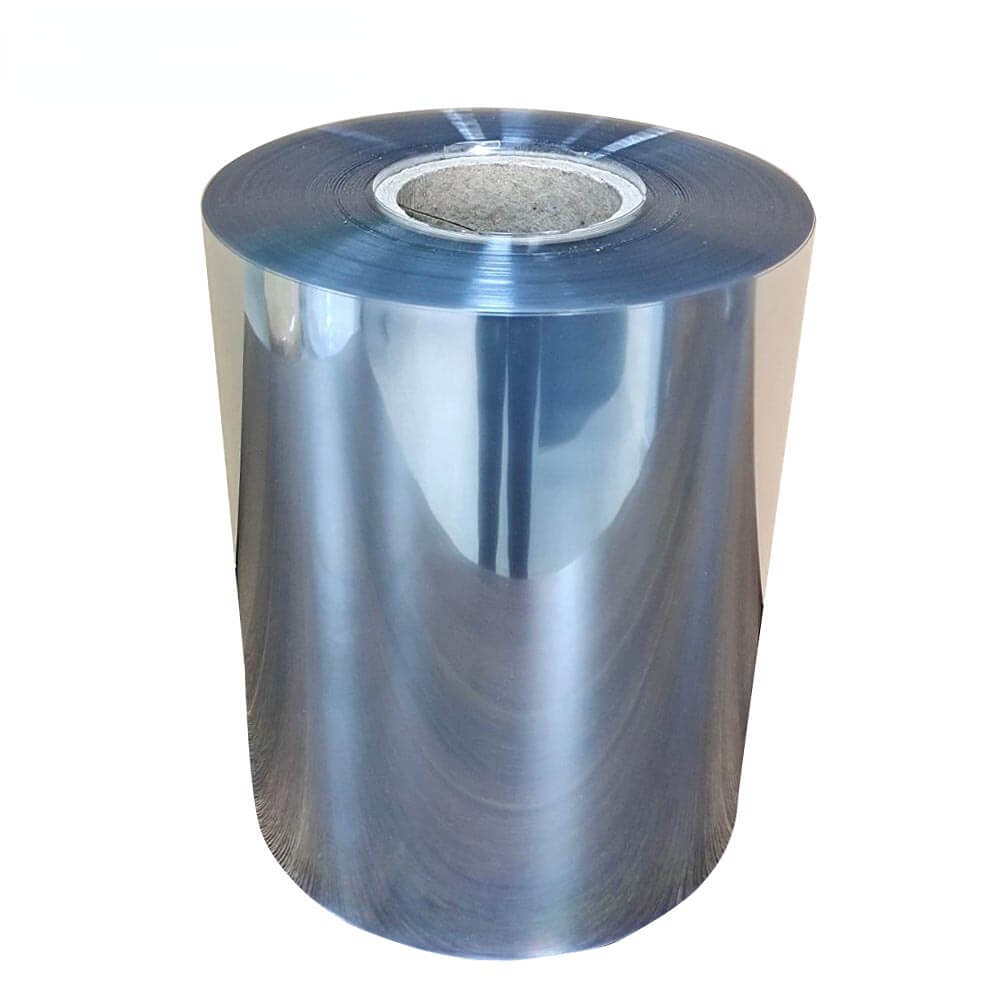

2. Transparency and Product Visibility

One of the most valued characteristics of PET plastic rolls is their excellent clarity.

Transparent packaging allows products to be showcased effectively on retail shelves, enhancing consumer trust and promoting sales.

PET plastic sheet rolls maintain clarity even after thermoforming, making them superior to alternatives like HIPS or opaque plastics.

3. Thermoforming Performance and Durability

PET rolls offer outstanding thermoforming capabilities, allowing food packaging manufacturers to produce complex shapes with consistent thickness and structural integrity.

Their durability ensures resistance to cracking or deformation, which is critical for automated packaging lines and high-volume production.

4. Lightweight and Cost-Efficient

PET is a lightweight material, which helps reduce overall packaging weight and lowers transportation costs.

Additionally, its strength-to-weight ratio allows manufacturers to use thinner sheets without compromising product protection, further improving cost efficiency.

5. Sustainability and Recyclability

With increasing environmental awareness, sustainable packaging solutions are becoming essential.

Food grade PET rolls are fully recyclable, compatible with existing recycling streams, and can support corporate sustainability initiatives.

Their use helps brands reduce environmental impact while maintaining high-quality packaging standards.

Why Food Packaging Factories Prefer PET Plastic Rolls?

From a procurement perspective, food packaging factories prioritize materials that combine consistent quality, production reliability, and regulatory compliance.

PET plastic rolls provide a stable supply of high-performance sheets, minimizing production disruptions and ensuring batch-to-batch consistency.

Additionally, their versatility allows integration with a variety of automated thermoforming machines, reducing downtime and operational costs.

Manufacturing Requirements for High-Quality PET Plastic Rolls

Producing reliable food grade PET rolls requires precise control over several factors:

- Thickness tolerance: Ensures uniform sheet performance in thermoforming.

- Surface cleanliness: Avoids contamination during packaging.

- 100% virgin raw material: Guarantees chemical safety and optical clarity.

- Batch consistency: Critical for large-scale production.

- In-house quality control: Enables monitoring from raw material sourcing to final roll inspection.

Meeting these manufacturing requirements is essential for suppliers who aim to support leading food packaging factories.

Why Leading Food Packaging Factories Choose Desu PET Plastic Rolls?

Desu (pet-sheet) has established itself as a trusted manufacturer of food grade PET plastic rolls, serving food packaging factories worldwide. Key advantages include:

- Specialized Expertise: Desu focuses exclusively on food-grade PET, ensuring in-depth knowledge of industry requirements and packaging applications.

- Strict Quality Control: Each roll undergoes rigorous testing for thickness tolerance, optical clarity, and regulatory compliance.

- Reliable Bulk Supply: With modern manufacturing facilities, Desu guarantees consistent delivery of large volumes to meet the demands of high-volume packaging lines.

- Customization Capabilities: Desu offers flexible options for roll width, thickness, and surface finish, enabling tailored solutions for different food packaging formats.

- Proven Track Record: Leading factories rely on Desu for their critical packaging needs, benefiting from reduced operational risk and improved production efficiency.

By aligning product quality with industry standards and factory requirements, Desu PET plastic rolls help manufacturers achieve reliable, safe, and visually appealing packaging solutions.

The Future of Food Grade PET Rolls in Packaging

As food safety regulations tighten and consumer demand for high-quality, sustainable packaging grows, the adoption of food grade PET rolls is expected to rise.

Their combination of clarity, thermoforming performance, and environmental compatibility positions them as an indispensable material for modern food packaging.

Manufacturers seeking to maintain competitive advantage increasingly turn to trusted suppliers like Desu, who can deliver both technical expertise and consistent production quality.

In conclusion, food grade PET plastic rolls are more than just packaging materials—they are a strategic component in ensuring food safety, operational efficiency, and consumer satisfaction.

With professional suppliers like Desu, food packaging factories can confidently meet the demands of today’s dynamic market while preparing for the sustainable packaging trends of the future.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM