What is PET plastic rolls used for?

Introduction of PET Plastic Rolls

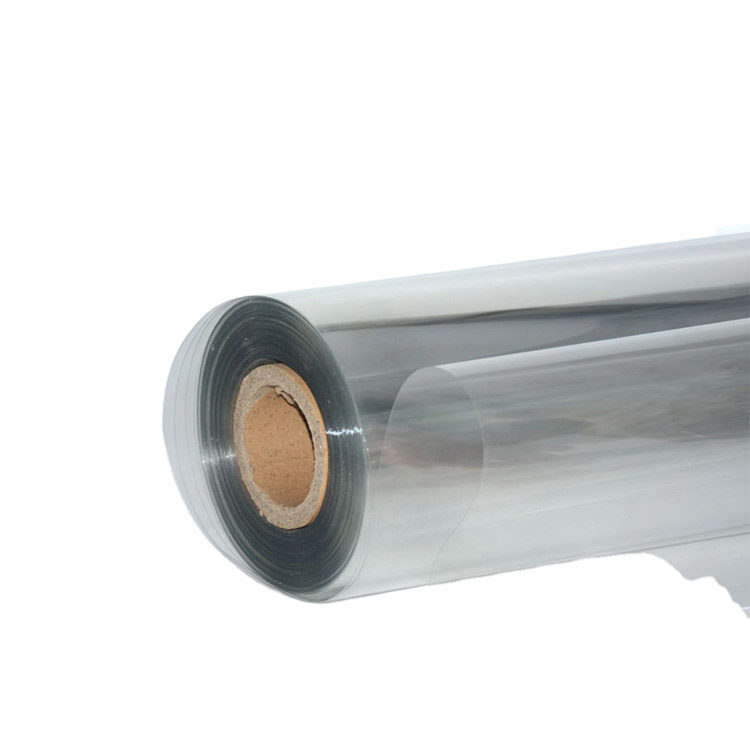

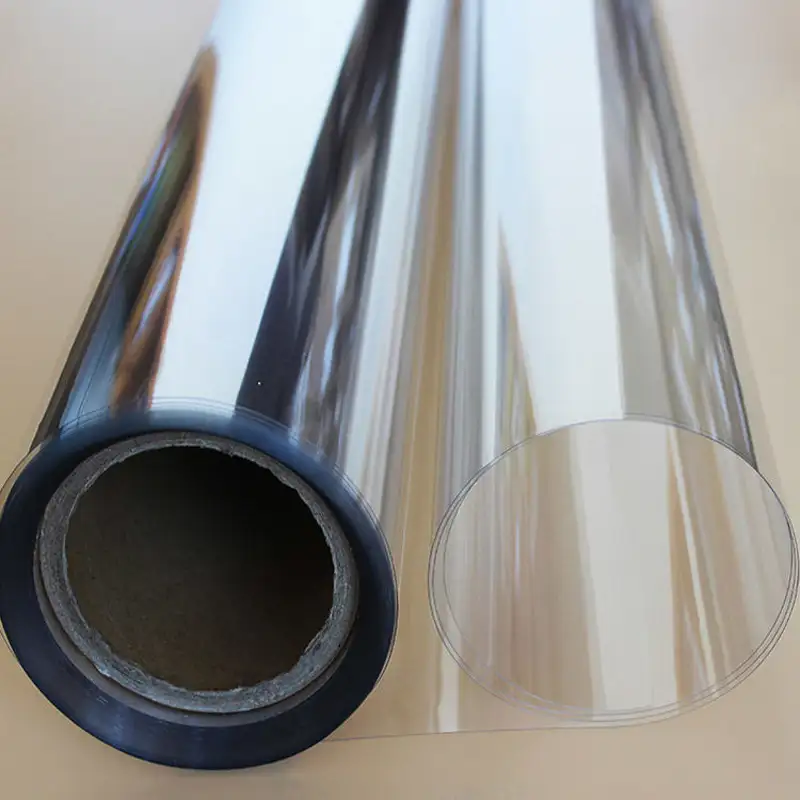

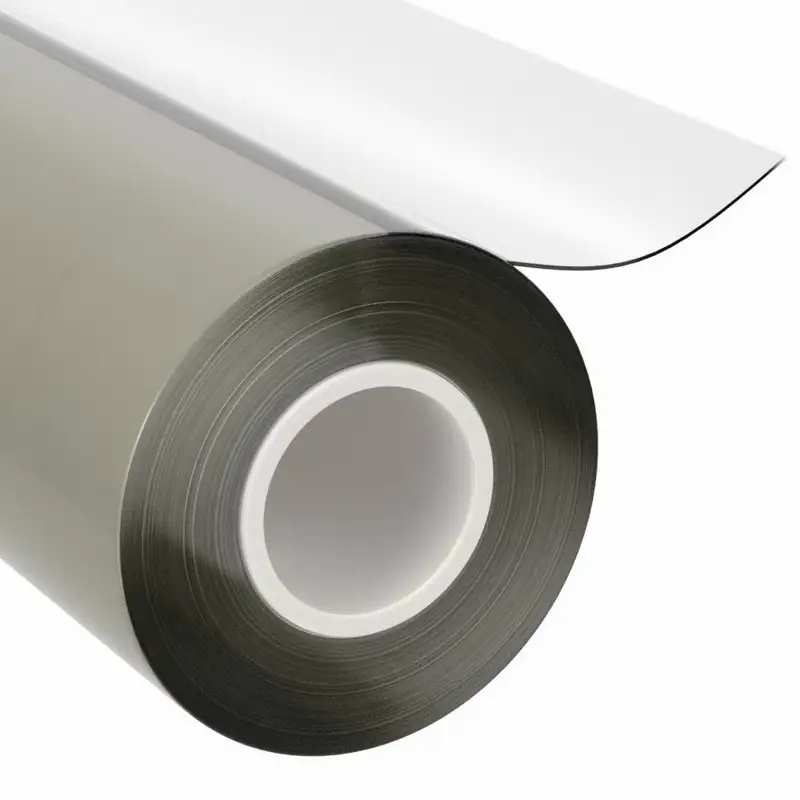

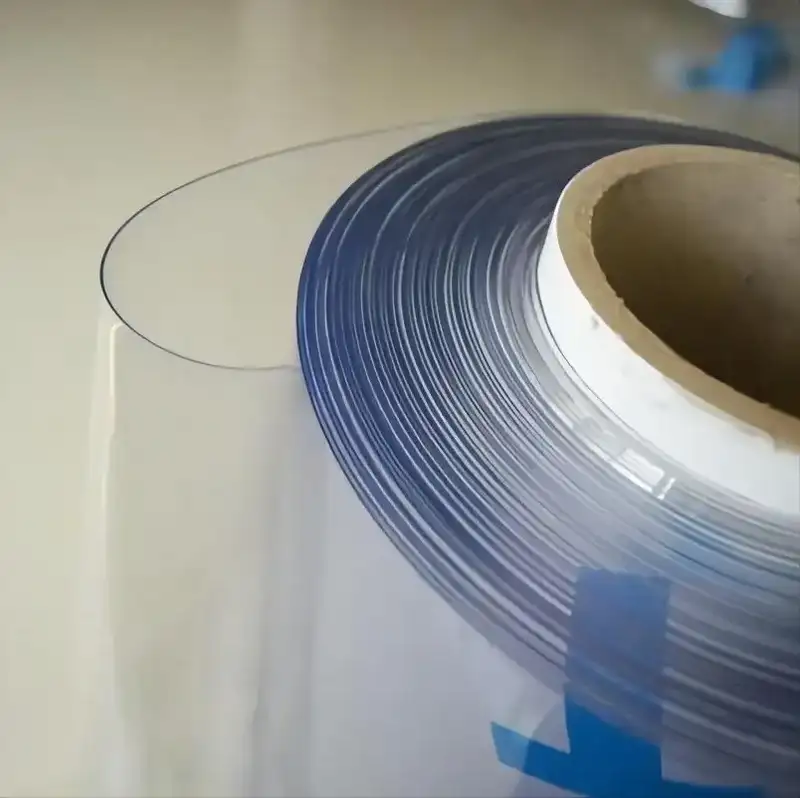

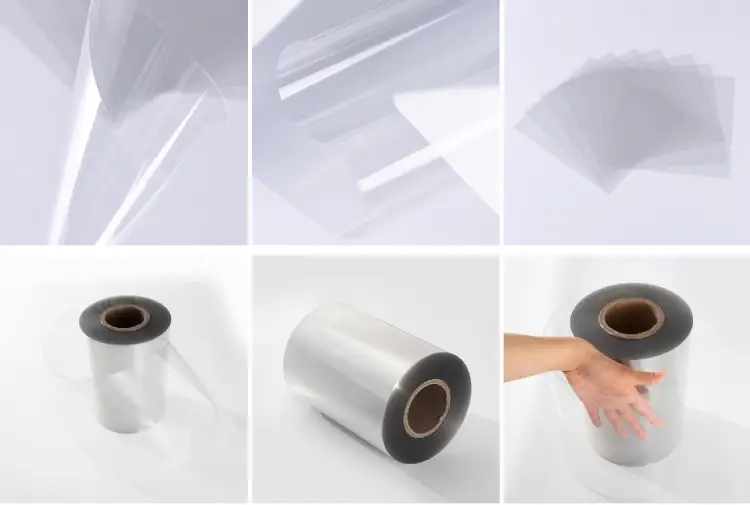

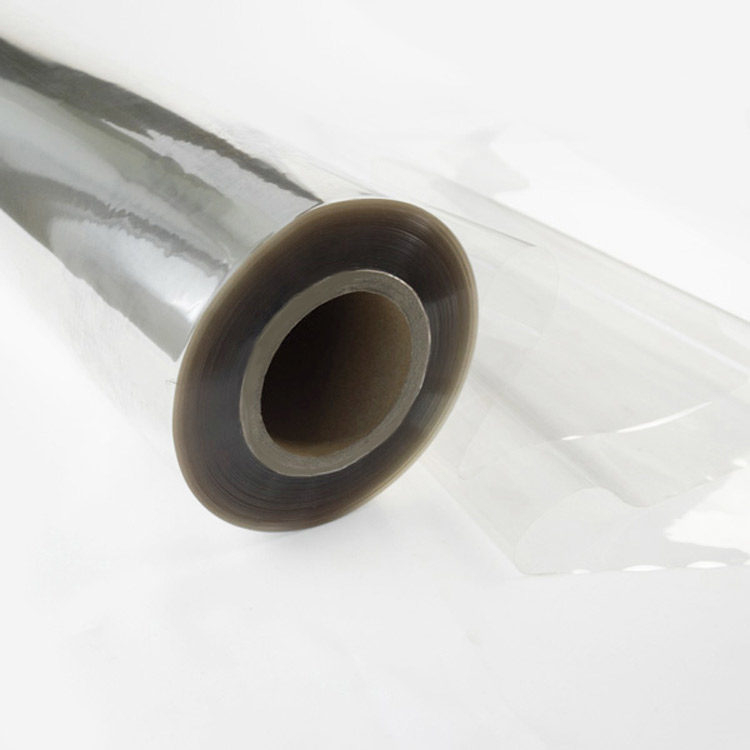

PET plastic rolls, short for Polyethylene Terephthalate sheet rolls, are a type of thermoplastic polyester film known for their high transparency, strong impact resistance, and excellent thermoforming performance. PET plastic rolls are widely used to produce packaging materials that require both clarity and durability.

These rolls are produced through extrusion and winding processes, forming continuous sheets that can later be thermoformed, vacuum-formed, or die-cut into various shapes for packaging or industrial applications. Depending on the production needs, PET plastic rolls can be clear, colored, anti-static, or coated to meet specific customer requirements.

Common Applications of PET Plastic Rolls

PET Plastic Rolls (Polyethylene Terephthalate) are widely used across multiple industries thanks to their high transparency, excellent strength, and easy thermoforming properties. Below are the main application areas:

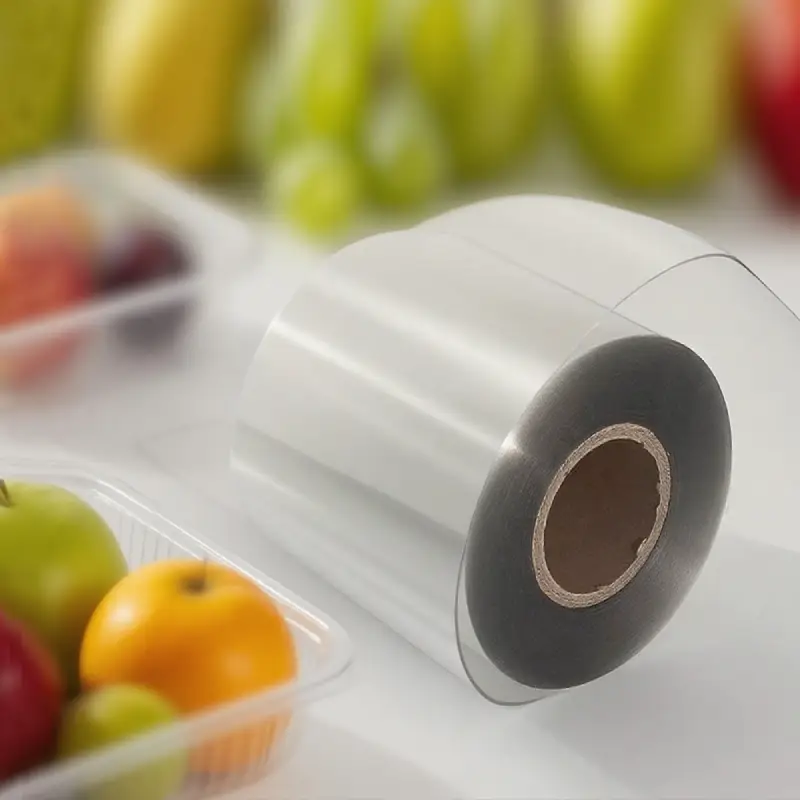

1. Food Packaging

PET rolls are one of the most popular materials in the food industry. They are used to produce:

Thermoformed trays, clamshells, lids, and blister packs for fruits, vegetables, bakery items, meat, and confectionery.

Sealable food containers that keep products fresh and protected from moisture and contamination.

Display packaging that highlights the product’s visual appeal on store shelves.

2. Medical and Pharmaceutical Packaging

Because PET is non-toxic, odorless, and hygienic, it’s ideal for healthcare use:

Medical blister packs, tablet trays, and sterile component packaging.

Protective covers for medical instruments and diagnostic kits.

3. Electronics and Industrial Packaging

PET rolls offer high impact resistance and stability, making them suitable for:

Anti-static trays for electronic components and precision devices.

Protective covers and inserts used during electronic assembly and transport.

Industrial forming sheets for tools, devices, and hardware packaging.

4. Cosmetic and Personal Care Packaging

PET rolls are often used in cosmetic blister packs, display boxes, and transparent covers that showcase products such as skincare bottles, perfumes, and makeup kits while providing strong protection.

5. Printing and Display Applications

PET sheets are also used for printing, signage, and display panels because of their smooth surface and excellent clarity. They can be easily printed, laminated, or die-cut for branding and promotional purposes.

6. Clamshell and Blister Packaging

PET is the preferred choice for thermoformed clamshells and blister packs due to its formability, rigidity, and recyclability — suitable for electronics, toys, stationery, and retail consumer goods.

Advantages of PET Plastic Rolls

PET plastic rolls offer a unique combination of aesthetic appeal, functionality, and environmental benefits, making them one of the most preferred materials in global packaging markets.

1. High Transparency: PET offers exceptional clarity that allows perfect product visibility, making it ideal for retail packaging.

2. Excellent Thermoforming Performance: It maintains uniform thickness and strength after forming, ensuring high production efficiency and consistent results.

3. Impact Resistance: PET is tougher and more durable than traditional plastics, providing excellent protection during transport and handling.

4. Chemical Resistance: It resists oils, greases, and chemicals, keeping products safe and clean.

5. Eco-Friendly & Recyclable: PET is a fully recyclable plastic, aligning with global sustainability trends and reducing environmental impact.

6. Food Safety Compliance: PET materials are approved for direct food contact by major international standards, including FDA and EU regulations.

7. Lightweight Yet Strong: PET offers excellent strength-to-weight ratio, reducing transportation costs and material usage.

Who Are PET Plastic Rolls Suitable For?

| Type of Manufacturer / Company | Typical Products or Uses | Pain Points (Challenges) | How PET Rolls Solve the Problem |

|---|---|---|---|

| Food Packaging Manufacturers | Trays, clamshells, blister packs, containers for fruits, bakery, meat | Poor transparency, uneven thickness, hygiene issues, material not food-safe | Crystal-clear clarity, uniform thickness, FDA-approved food safety |

| Thermoforming Factories | Thermoformed trays, lids, and blister shells | Unstable forming performance, cracking, inconsistent roll quality | Excellent thermoforming performance and consistent sheet thickness |

| Electronics Packaging Companies | Anti-static trays, protective covers, precision part packaging | Brittle materials, static buildup damaging components | Tough, optional anti-static treatment, shape stability |

| Cosmetics & Personal Care Packaging | Transparent covers, folding boxes, blister packs | Poor visual appeal, low transparency, deformation after forming | High gloss, superior transparency, stable shape retention |

| Medical & Pharmaceutical Packaging Companies | Blister packs, medical trays, sterile packaging | Safety and hygiene concerns, inconsistent material quality | Non-toxic, odorless, hygienic — suitable for medical-grade packaging |

| Printing & Display Product Manufacturers | Printed signage, labels, display boards | Surface not smooth enough for printing, poor color adhesion | Smooth surface and excellent ink adhesion for vibrant, durable prints |

| Industrial Product Packaging Companies | Hardware, tools, and component packaging | Weak materials, poor impact resistance during shipping | Impact-resistant and durable, offering reliable protection in transit |

| Retail Product Packaging Producers | Toys, stationery, small consumer goods packaging | Low clarity, unattractive packaging, low recycling rate | Enhances product visibility and is 100% recyclable for eco-branding |

Why Choose DESU (pet-sheet.com) as Your PET Plastic Roll Supplier?

When it comes to high-quality PET plastic sheet rolls, DESU (pet-sheet.com) is a trusted and factory-qualified manufacturer based in China, with years of experience in thermoforming and blister packaging materials. Here’s why customers around the world choose DESU:

1. Factory-Direct Manufacturing

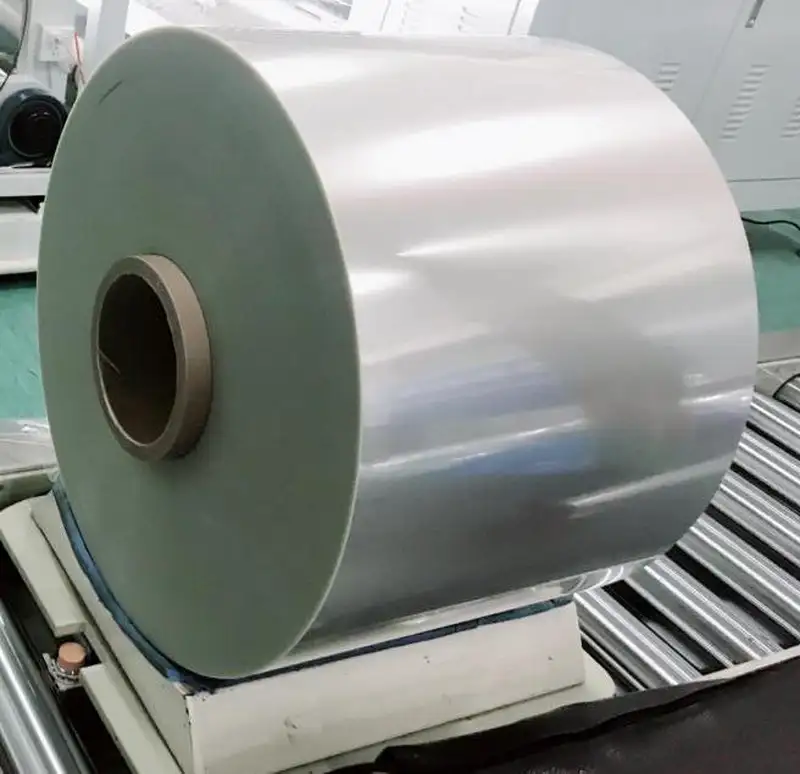

DESU owns modern production facilities equipped with advanced extrusion lines, ensuring consistent thickness, clarity, and mechanical properties. Every roll is produced under strict quality control to guarantee reliability and precision.

2. Customization Options

The company provides customized PET rolls in different thicknesses (from 0.2mm to 2mm), colors, surface finishes, and widths to meet diverse industrial needs. Anti-fog, anti-static, and UV-resistant types are also available.

3. Excellent Clarity and Smoothness

DESU’s PET rolls are known for their crystal-clear transparency, low haze, and smooth surface, which enhance the appearance and value of packaged products.

4. Stable Supply and Fast Delivery

With multiple production lines and large inventory capacity, DESU ensures steady supply, short lead times, and global shipping support, helping customers keep their projects on schedule.

5. Competitive Pricing and Global Service

By operating as a direct manufacturer with efficient cost control, DESU offers factory prices without compromising on quality. The company also provides professional English-speaking sales support to assist customers from inquiry to delivery.

6. Sustainable and Responsible Production

As sustainability becomes a global priority, DESU focuses on eco-friendly production using recyclable materials and energy-efficient processes. The company actively supports clients looking to switch from PVC to PET to reduce environmental impact.

The Future of PET Plastic Rolls

The demand for PET plastic rolls continues to grow as industries shift toward sustainable and high-performance materials. Whether in food packaging, healthcare, electronics, or consumer goods, PET remains a preferred solution due to its clarity, strength, and recyclability.

Manufacturers and brand owners seeking a dependable PET packaging supplier can rely on DESU (pet-sheet.com) to provide customized, high-quality, and cost-effective PET sheet rolls for global applications.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM