Why a Dutch Customer Reordered for the 6th Time?

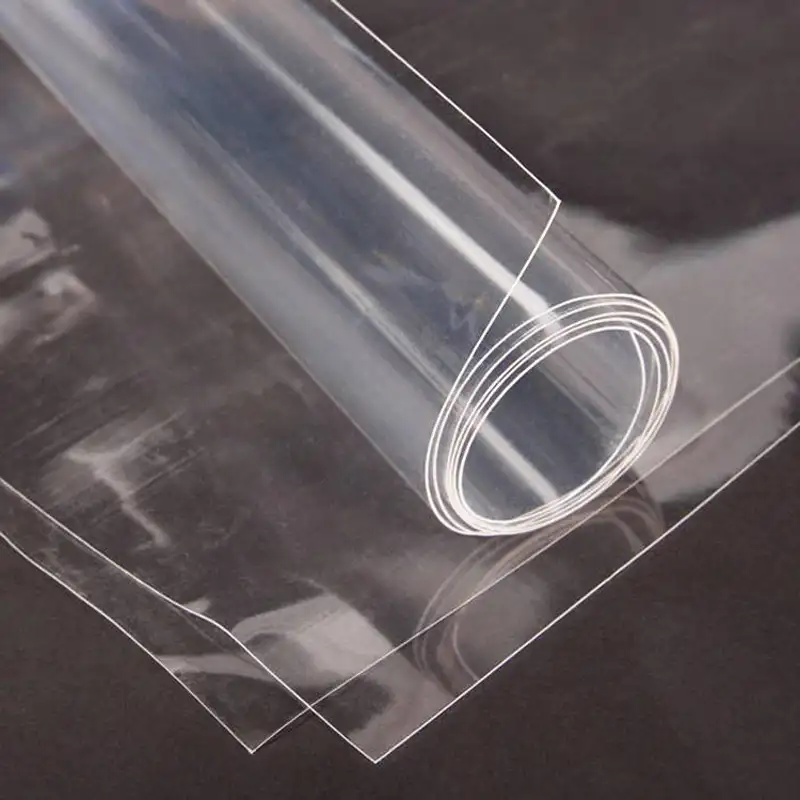

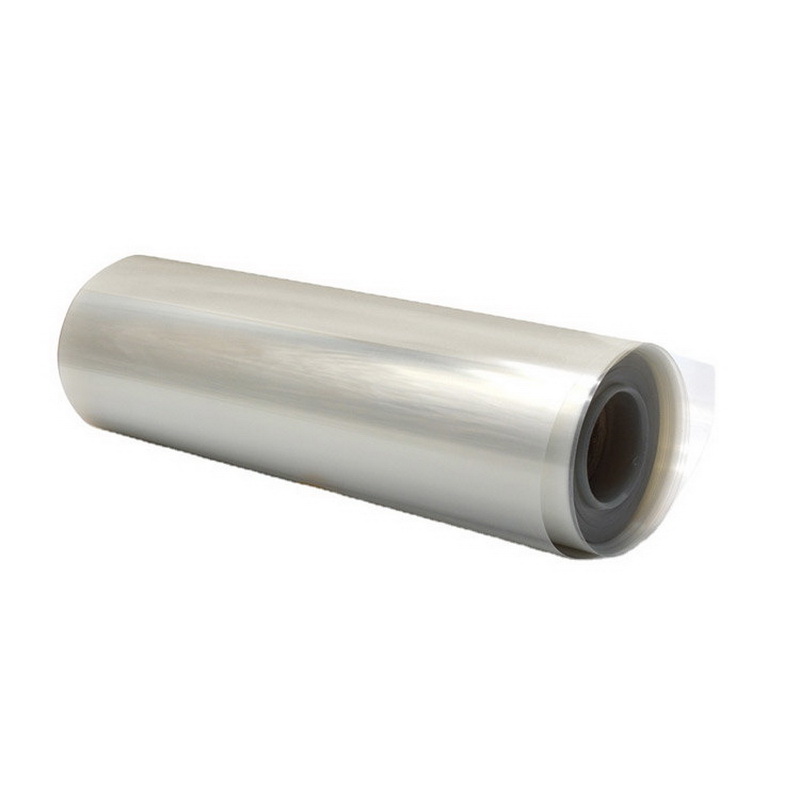

A 25-Ton Food-Grade PET Sheet Roll Shipment from DESU

In B2B packaging materials, one shipment does not prove reliability.

Repeat orders do.

Recently, DESU completed the shipment of 25 metric tons of food-grade PET sheet rolls to the Netherlands.

Specification: 0.6 mm × 650 mm, used for thermoformed food packaging.

This was the customer’s 6th repeat order.

This article is not about promotion.

It explains why a European food packaging buyer continues to choose the same PET sheet specification, the same supplier, and the same production logic—and how those decisions are made.

1. Repeat Orders Answer the Real Question: “Are You a One-Time Supplier?”

For overseas procurement teams, the first concern is rarely price.

It is risk.

- Will the material behave the same in production?

- Will the next batch match the last one?

- Will the supplier disappear after one container?

A 6th repeat order is not accidental.

It means the material has already passed multiple internal filters on the buyer’s side:

- production trials

- forming efficiency validation

- food-contact compliance review

- logistics performance

- cost stability over time

In practice, repeat orders happen only when switching costs are higher than staying.

For this Dutch customer, DESU became part of a stable supply system—not a transactional vendor.

2. Why 0.6 mm × 650 mm?

Specification Selection Is Not Arbitrary

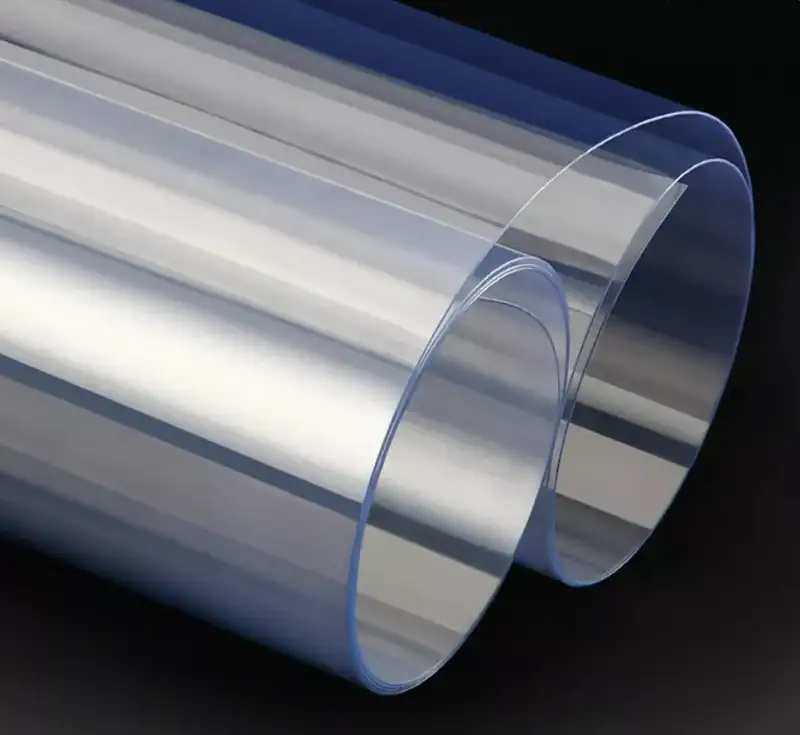

From the outside, 0.6 mm × 650 mm looks like a simple specification.

In reality, it reflects a long-term optimization process.

Thickness: Why 0.6 mm?

For food thermoforming, thickness selection balances four factors:

- Forming rigidity – tray stiffness after forming

- Material draw ratio – wall thickness uniformity

- Cycle time – heating and forming speed

- Cost per unit – resin consumption per tray

At 0.6 mm, this customer achieved:

- stable forming without excessive heating

- predictable thickness distribution in cavities

- sufficient rigidity for sealing and stacking

- lower material waste compared to thicker sheets

Thinner sheets reduced rigidity; thicker sheets increased cost without added benefit.

0.6 mm became the process sweet spot.

Width: Why 650 mm?

The width was matched precisely to:

- thermoformer clamping dimensions

- trimming layout

- downstream automation width

Changing width would mean tooling changes, trimming loss, and downtime.

Once validated, buyers rarely change it.

This is why long-term buyers care less about “available sizes” and more about repeatable custom dimensions.

3. How We Control Food-Grade Quality

From Production Reality, Not Certificates Alone

Food-grade PET is not just about compliance documents.

It is about process discipline.

In real production, food-grade control happens at three levels:

1) Raw Material Discipline

- Only approved virgin PET resin grades

- No regrind from non-food applications

- Clear segregation of food vs non-food production runs

2) Extrusion Process Control

- Dedicated production scheduling for food-grade orders

- Stable melt temperature to avoid degradation

- Continuous thickness and surface monitoring

- Controlled cooling to prevent internal stress

These are not marketing claims.

They are daily operational constraints that affect yield, scrap rate, and consistency.

3) Batch Consistency for Repeat Orders

For repeat customers, process parameters are locked, not reinvented.

- same resin supplier

- same extrusion line

- same target thickness profile

This is how the 6th shipment matches the 1st—not by chance.

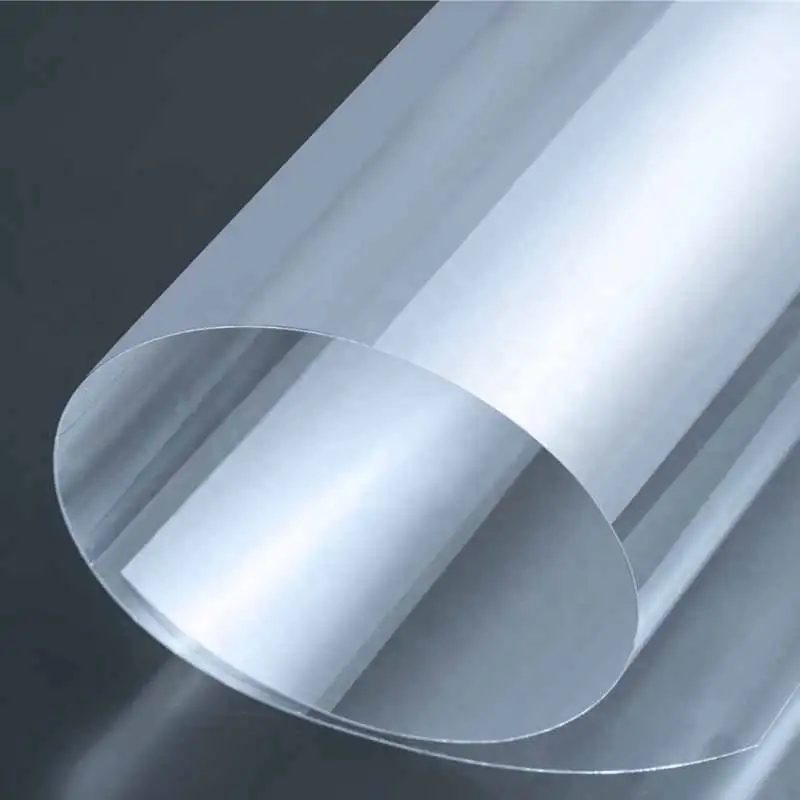

4. Thermoforming Performance Is the Real Proof

Ultimately, PET sheet quality is judged on the thermoforming machine, not in the warehouse.

For this customer’s application:

- sheets heat evenly

- forming window is stable

- no unexpected thinning at corners

- clean trimming without cracking

- stable sealing performance

Good forming behavior reduces:

- machine stoppages

- scrap during startup

- operator intervention

Over time, these savings outweigh small differences in material price.

This is why production teams often influence re-order decisions more than purchasing alone.

5. Logistics & Export: Solving the Buyer’s Hidden Anxiety

International buyers worry about more than material quality:

- Will the rolls arrive damaged?

- Will customs clearance delay production?

- Will packaging survive long transit?

For EU shipments like this one, attention was paid to:

- roll protection and edge integrity

- moisture control

- pallet stability

- clear documentation for EU import

25 tons of PET sheet is not “just another container.”

If one roll is damaged, production schedules are affected.

Reliability in export logistics is often invisible—until it fails.

Repeat buyers notice when it does not.

6. The 6th Reorder Was a Decision, Not a Habit

This was not an automatic reorder.

Like most professional buyers, the customer reviewed:

- internal consumption rate

- forming yield from previous batches

- inventory turnover

- cost trends

Continuing with the same supplier meant:

- no new material testing

- no process revalidation

- no risk to ongoing contracts

In procurement terms, stability became the value.

7. What “10+ Years of Experience” Means in Practice

Experience is not a slogan.

It shows up in specific capabilities:

- understanding how PET behaves under different forming conditions

- knowing when to adjust process—not just formulation

- delivering consistent results across multiple shipments

- communicating in production language, not sales language

After 10+ years, the focus shifts from “selling material” to supporting production systems.

8. Advice for Overseas PET Sheet Buyers

If you are sourcing food-grade PET sheet for thermoforming, consider:

- Evaluate repeatability, not first samples

- Choose specifications that fit your forming reality, not catalog sizes

- Ask how food-grade is controlled in production, not just certified

- Factor logistics reliability into total cost

- Value suppliers who understand your process, not just your PO

In packaging, the best supplier is often the one you don’t have to think about.

About DESU

DESU is a PET sheet manufacturer with over 10 years of experience, supplying food-grade PET sheet rolls for thermoforming packaging customers worldwide.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM