Why choose Food Grade PET Plastic Rolls as the raw material for food packaging?

Introduction

As global food safety regulations continue to tighten, food packaging manufacturers and brand owners are placing greater emphasis on the selection of safe, reliable, and sustainable raw materials. Among various plastic materials available on the market, Food Grade PET Plastic Rolls have become one of the most widely used and trusted choices for modern food packaging applications.

This article explains why food grade PET plastic rolls are preferred in food packaging and why professional manufacturers choose Desu (pet-sheet.com) as their long-term PET sheet supplier.

Growing Demand for Safe and Reliable Food Packaging Materials

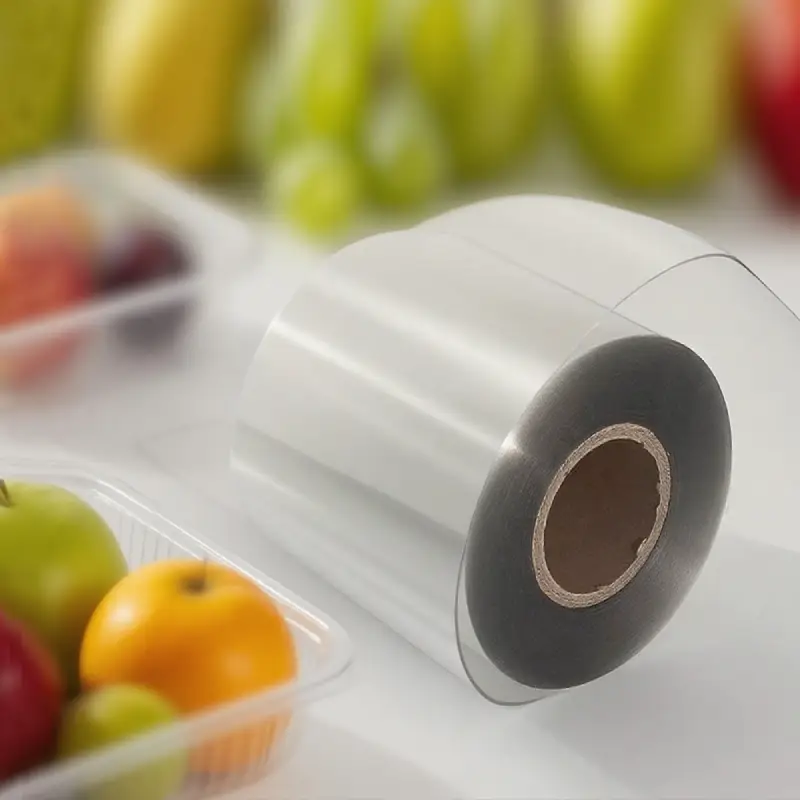

Food packaging plays a critical role in protecting products, extending shelf life, and ensuring consumer safety. Governments and regulatory bodies worldwide have introduced stricter food contact material standards, requiring packaging materials to be non-toxic, odorless, and compliant with international regulations.

As a result, food packaging manufacturers increasingly favor materials that combine food safety, performance stability, and environmental responsibility—making food grade PET plastic rolls a natural choice.

What Are Food Grade PET Plastic Rolls?

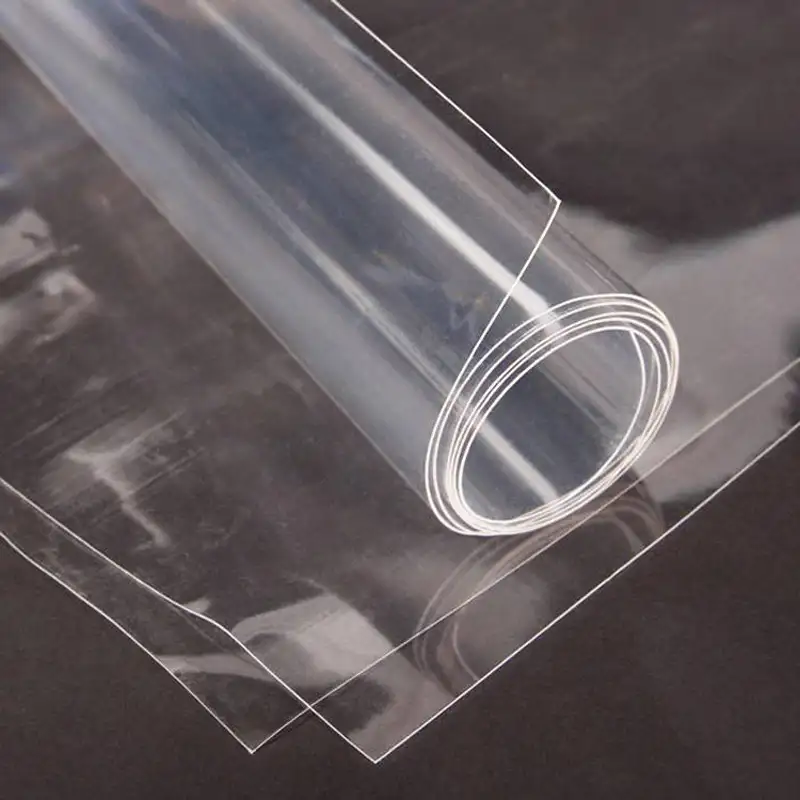

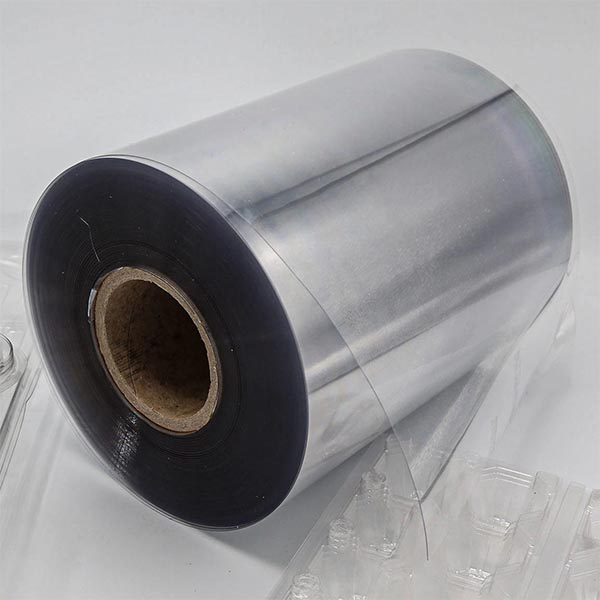

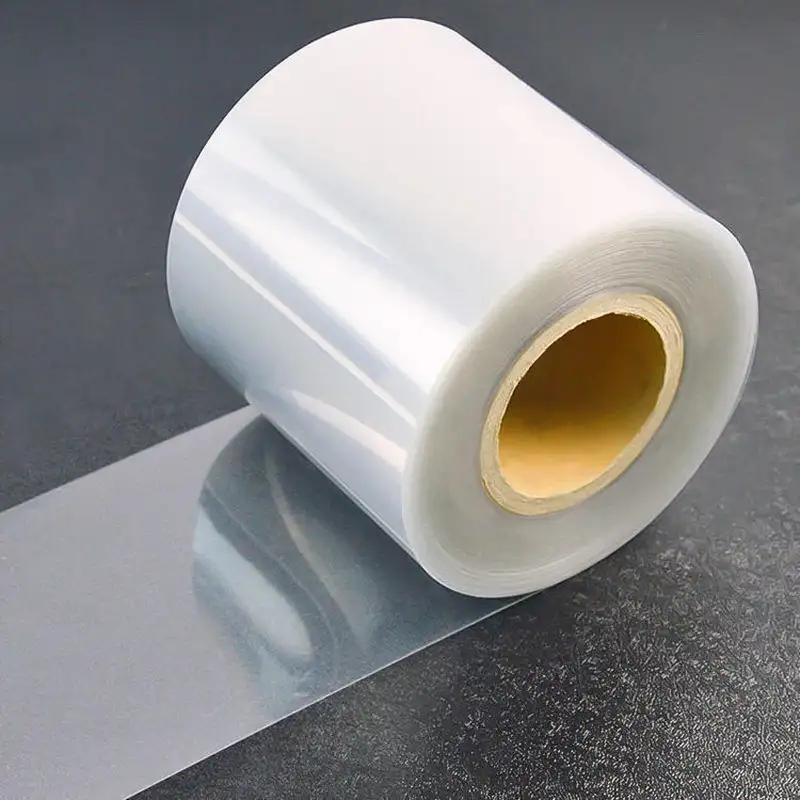

Food grade PET plastic rolls are plastic sheet materials manufactured from high-quality PET (Polyethylene Terephthalate) resin that meets food contact safety requirements. These materials are specifically designed for direct or indirect contact with food products.

Compared with general-purpose plastic sheets, food grade PET rolls offer:

- Certified food safety compliance

- Stable physical and chemical properties

- Consistent quality suitable for automated thermoforming lines

They are commonly used in thermoforming, blister packaging, and other food packaging processes.

Key Advantages of Food Grade PET Plastic Rolls for Food Packaging

1. Excellent Food Safety and Non-Toxic Properties

Food grade PET is free from harmful additives and does not release odors or contaminants during processing. It is safe for direct food contact and widely accepted in applications involving fresh food, bakery products, dairy items, and ready-to-eat meals.

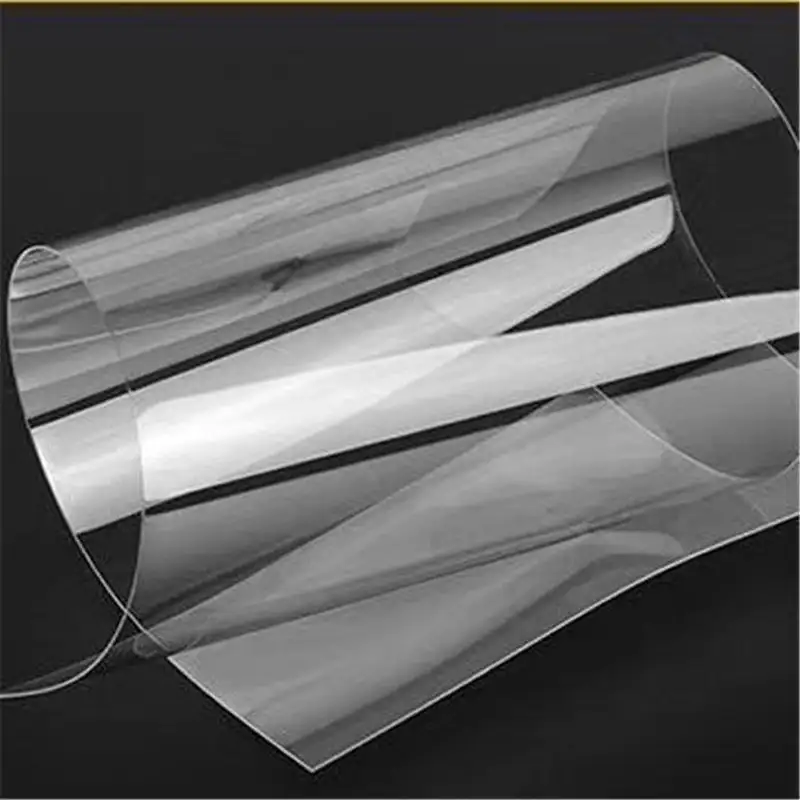

2. High Transparency and Premium Appearance

PET plastic rolls offer outstanding clarity and gloss, allowing food products to be clearly visible on store shelves. This transparency enhances product presentation, improves consumer trust, and supports premium brand positioning.

3. Outstanding Thermoforming Performance

For food packaging manufacturers, stable processing performance is essential. PET plastic rolls provide:

- Uniform thickness distribution

- Smooth forming behavior

- Reduced scrap rates during thermoforming

These advantages help improve production efficiency and lower overall manufacturing costs.

4. Strong Mechanical Strength and Impact Resistance

Food grade PET plastic rolls offer excellent mechanical strength and impact resistance, ensuring that packaging maintains its shape during transportation, storage, and handling. This durability makes PET suitable for trays, containers, cups, and lids used across various food categories.

5. Environmentally Friendly and Recyclable

Sustainability has become a key concern in food packaging. PET is a 100% recyclable material and is widely collected and recycled globally. Choosing PET plastic rolls supports environmentally responsible packaging strategies and aligns with sustainability goals set by food brands and regulators.

Why Food Packaging Manufacturers Choose PET Over Other Materials?

Compared with traditional materials such as PVC, PS, or some PP applications, PET offers a better balance of:

| Comparison Factor | PET (Food Grade) | PVC | PS | PP |

|---|---|---|---|---|

| Food Contact Safety | Excellent, widely approved for food contact applications | Limited acceptance, safety concerns in some markets | Acceptable but brittle | Acceptable, depends on formulation |

| Transparency & Appearance | High clarity and gloss, premium visual appeal | Good transparency but aging issues | Moderate, less premium look | Low to medium transparency |

| Thermoforming Performance | Excellent forming stability and thickness consistency | Good forming, but limited sustainability | Easy forming, but high breakage risk | Requires higher forming temperatures |

| Mechanical Strength & Impact Resistance | Strong and durable, crack-resistant | Moderate strength | Brittle, prone to cracking | Good toughness |

| Temperature Resistance | Suitable for cold and ambient food packaging | Limited temperature range | Poor heat resistance | Better heat resistance |

| Environmental Friendliness | 100% recyclable, widely recycled globally | Poor recyclability | Limited recyclability | Recyclable, but lower recovery rate |

Why Choose Desu (Pet-sheet) Food Grade PET Plastic Rolls?

1. Strict Raw Material Selection and Quality Control

Desu uses carefully selected PET raw materials and follows strict production standards to ensure every roll meets food grade requirements. Quality control is implemented throughout the production process to guarantee consistent performance.

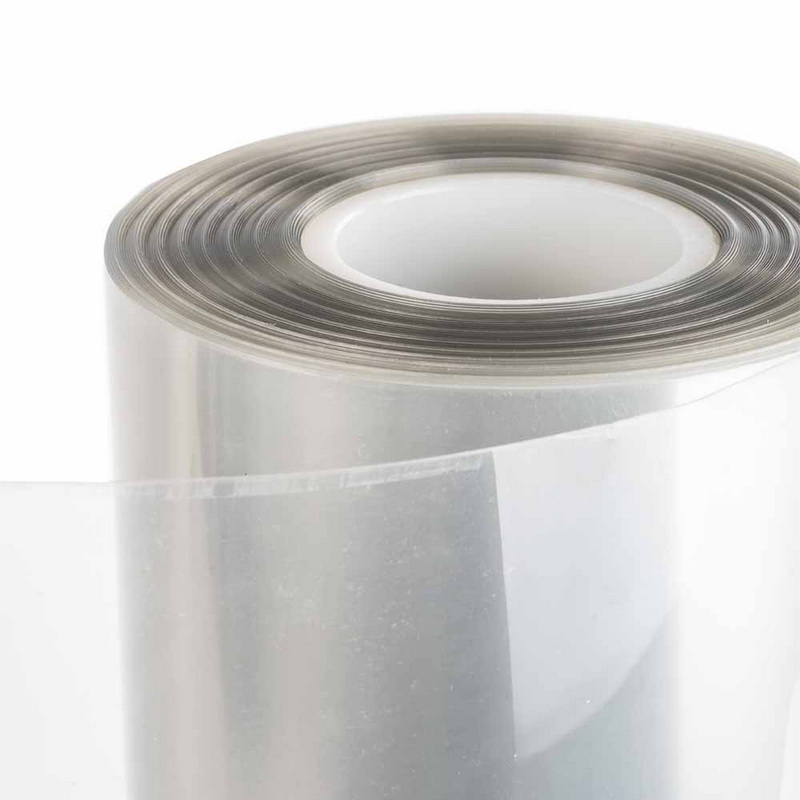

2. Stable Thickness, Width, and Surface Quality

Consistent sheet quality is critical for high-speed thermoforming lines. Desu food grade PET plastic rolls are known for their:

- Stable thickness tolerance

- Smooth surface finish

- Reliable roll structure

This stability helps customers achieve higher efficiency and lower production risk.

3. Customized Specifications for Food Packaging Applications

Different food packaging products require different material specifications. Desu provides customized PET plastic rolls, including:

- Thickness customization

- Width and roll diameter options

- Tailored solutions for various thermoforming designs

4. Reliable Supply and Professional Export Experience

With stable production capacity and extensive export experience, Desu supplies food grade PET plastic rolls to customers worldwide. The company supports long-term cooperation with food packaging manufacturers, distributors, and project-based buyers.

Typical Food Packaging Applications of PET Plastic Rolls

Food grade PET plastic rolls are widely used in:

- Thermoformed food trays

- Blister food packaging

- Disposable food containers and lids

- Fresh food and takeaway packaging

Conclusion: A Safe, Efficient, and Sustainable Choice for Food Packaging

Food grade PET plastic rolls offer an ideal combination of food safety, processing efficiency, durability, and sustainability, making them one of the most reliable raw materials for modern food packaging.

By choosing Desu (pet-sheet.com) as your PET plastic rolls supplier, food packaging manufacturers gain access to stable quality, professional manufacturing support, and a dependable long-term partner in the global packaging market.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM