Why Electronics Packaging Manufacturers Are Choosing ESD PET Plastic Rolls?

Introduction: Growing Challenges in Electronics Packaging

As electronic products become smaller, faster, and more sensitive, the risks associated with electrostatic discharge (ESD) have increased significantly. Components such as printed circuit boards (PCBs), integrated circuits (ICs), semiconductors, and sensors are highly vulnerable to static electricity during handling, transportation, and storage.

For electronics packaging manufacturers, protecting these sensitive components is no longer optional—it is a critical requirement. This growing demand for reliable anti-static packaging solutions has driven many manufacturers to choose ESD PET plastic sheet rolls as a preferred packaging material.

The Hidden Cost of Static Electricity in Electronic Products

Electrostatic discharge is often invisible, but its impact can be severe. Even a small static discharge can:

- Damage internal circuits without visible signs

- Reduce product lifespan

- Cause intermittent failures after installation

- Increase return rates and warranty claims

Traditional packaging materials such as ordinary PET, PS, or PVC sheets may offer mechanical protection, but they do little to control static electricity. As a result, electronics packaging manufacturers are under pressure to adopt materials that offer both physical protection and ESD safety.

What Is ESD PET Plastic Roll?

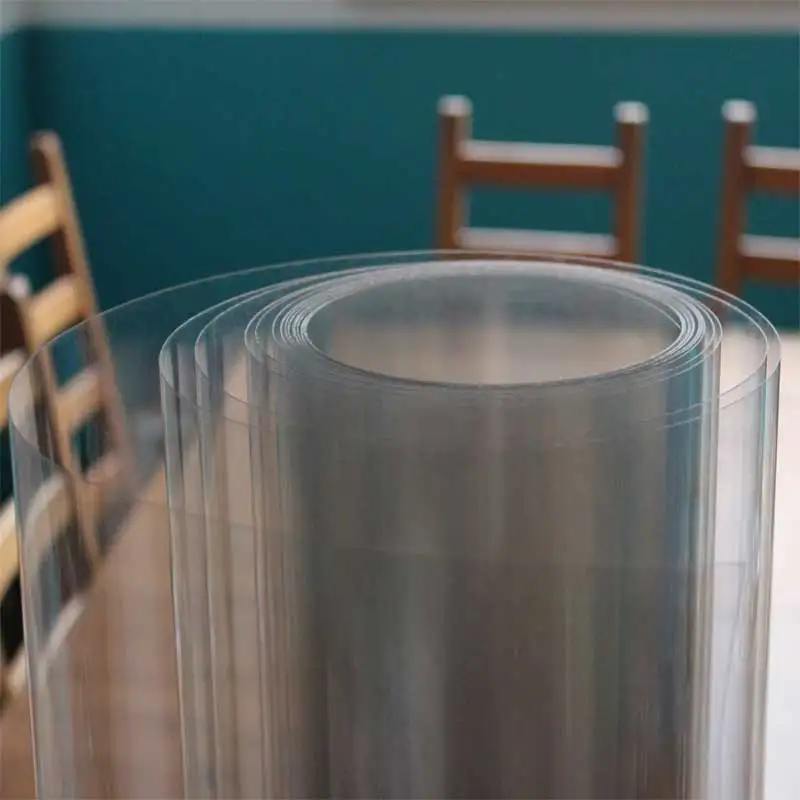

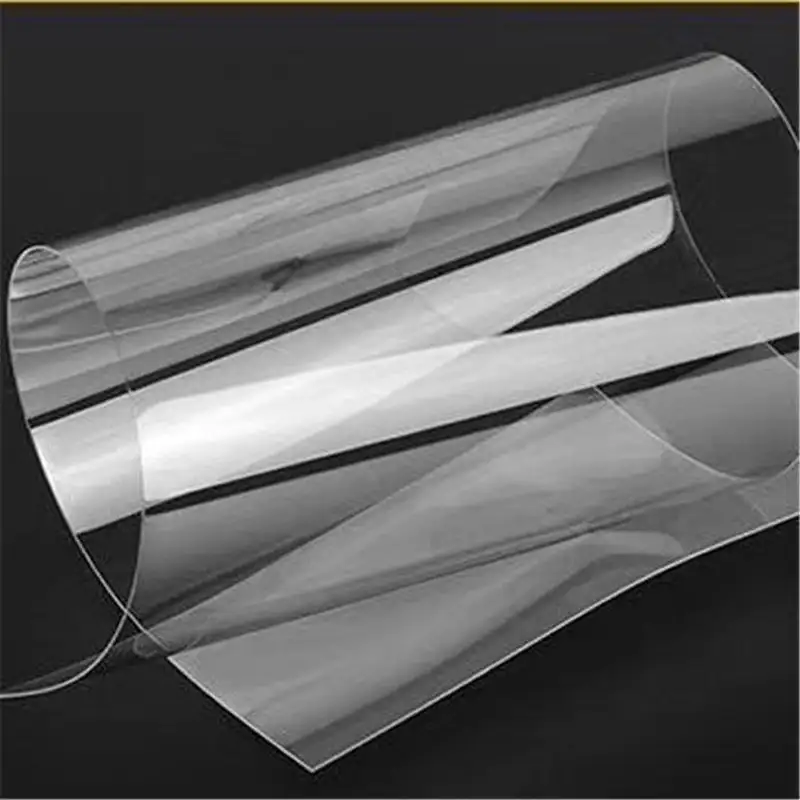

ESD PET Plastic Roll is an electrostatic discharge–controlled polyethylene terephthalate (PET) sheet supplied in roll form, specifically designed for packaging and thermoforming applications involving sensitive electronic components.

It combines the strength, clarity, and processability of standard PET with stable anti-static performance, typically featuring a controlled surface resistivity that safely dissipates static electricity.

ESD PET plastic rolls help protect PCBs, ICs, semiconductors, and electronic modules from ESD damage during handling, transportation, and storage, making them a reliable and widely used material in modern electronics packaging.

Reasons Why Electronics Packaging Manufacturers Choose ESD PET Plastic Rolls

1. Stable and Reliable ESD Protection

One of the main reasons electronics packaging manufacturers prefer ESD PET sheet rolls is their consistent anti-static performance. Unlike temporary anti-static coatings, ESD PET materials are designed to maintain their surface resistivity over time, even in varying humidity conditions.

This reliability is especially important for export packaging and long-distance transportation.

2. High Transparency for Product Visibility

ESD PET plastic rolls offer excellent transparency compared to traditional conductive materials, which are often black or opaque. Clear packaging allows:

- Easy visual inspection

- Faster quality control

- Improved automation and barcode scanning

This is particularly valuable for high-volume electronics manufacturing environments.

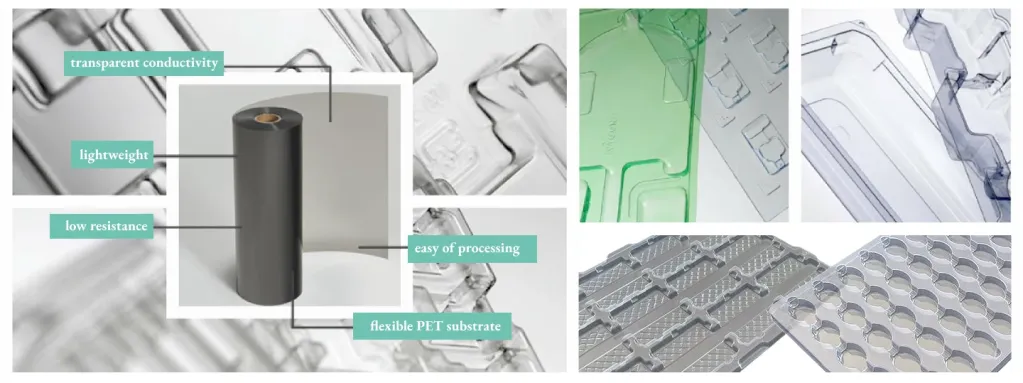

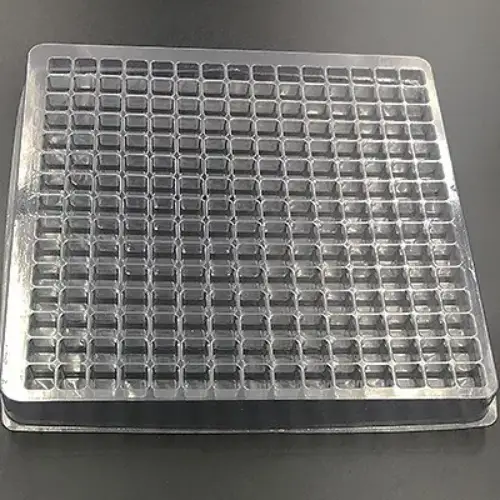

3. Excellent Thermoforming Performance

ESD PET sheet rolls are highly suitable for thermoforming processes, including:

- Vacuum forming

- Pressure forming

- Blister packaging

The material offers consistent heating behavior, precise forming details, and low scrap rates, helping packaging manufacturers improve production efficiency and reduce material waste.

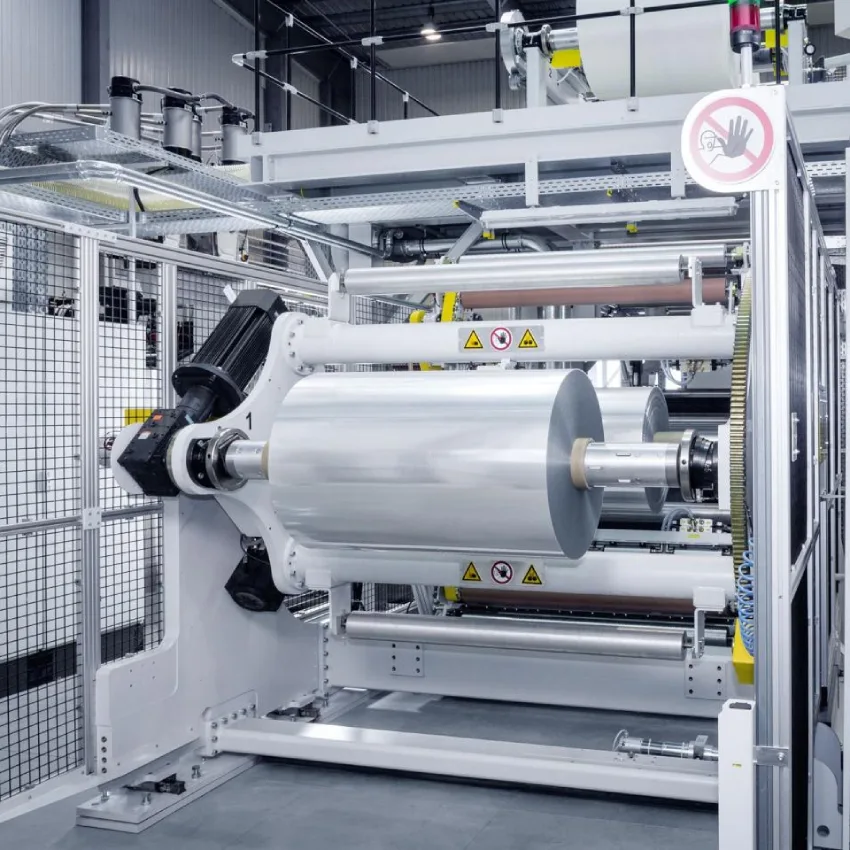

4. Compatibility with Automated Packaging Lines

Modern electronics packaging relies heavily on automation. ESD PET plastic sheets provide:

- Uniform thickness

- Smooth surface finish

- Stable dimensional tolerance

These characteristics ensure smooth operation on automated thermoforming and packaging equipment, reducing downtime and improving overall productivity.

5. Compliance with International Standards

ESD PET plastic sheet rolls are widely used in global electronics supply chains because they can meet key international requirements, including:

- ESD control standards (such as ANSI/ESD)

- RoHS compliance

- REACH environmental regulations

For packaging manufacturers serving multinational electronics brands, compliance is a decisive factor when selecting packaging materials.

Typical Applications in Electronics Packaging

ESD PET plastic sheet rolls are widely used across various electronics packaging applications, such as:

- PCB trays and carriers

- IC and semiconductor blister packaging

- Protective inner packaging for electronic modules

- Customized OEM and ODM electronics packaging solutions

Their versatility makes them suitable for both standard packaging designs and highly customized solutions.

Why Choose Desu(pet-sheet) ESD PET Plastic Rolls?

Electronics packaging manufacturers choose Desu (pet-sheet) ESD PET Plastic Rolls because of their proven reliability, consistent quality, and dependable long-term supply.

As a professional PET sheet manufacturer, Desu (pet-sheet) focuses on strict production control to ensure stable anti-static performance, uniform thickness, and excellent thermoforming behavior in every roll.

The controlled surface resistivity of Desu’s ESD PET helps protect sensitive electronic components from electrostatic discharge, reducing packaging risks and product failure rates.

In addition, Desu (pet-sheet) offers reliable batch-to-batch consistency, allowing packaging manufacturers to run automated production lines with confidence and minimal downtime.

With a strong manufacturing background, export experience, and commitment to quality assurance, Desu (pet-sheet) has become a trusted partner for electronics packaging manufacturers seeking a stable, long-term ESD PET plastic roll supplier.

Conclusion

ESD PET plastic roll is a professional packaging material that combines the advantages of electrostatic discharge control, transparency, strength, and processing stability.

As electronic products become more advanced and sophisticated, ESD PET plastic sheet rolls has become an essential solution for safe, efficient, and compliant packaging of electronic products. Please leave us a message for more information.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM