Why PET Plastic Sheet Rolls Are Transforming the Packaging Industry?

In recent years, the global packaging industry has undergone a remarkable transformation driven by sustainability goals, technological advancement, and consumer demand for high-quality and eco-friendly packaging. Among the materials leading this change, PET plastic sheet rolls (Polyethylene Terephthalate) have become one of the most preferred choices across industries—from food and beverage to electronics and pharmaceuticals. Their versatility, durability, and recyclability make them an essential solution for modern packaging challenges.

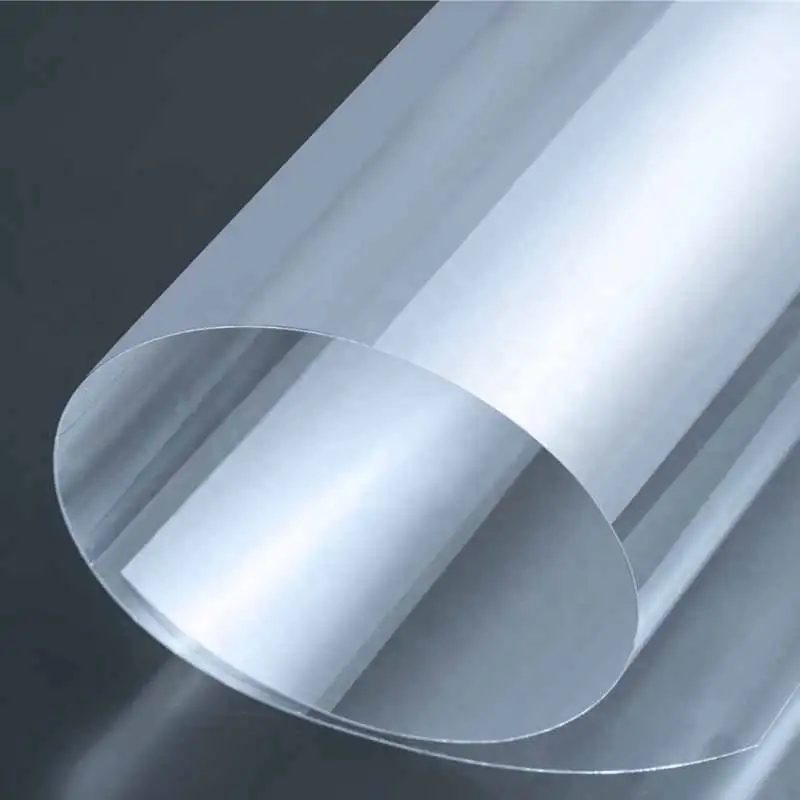

Understanding PET Plastic Sheet Rolls

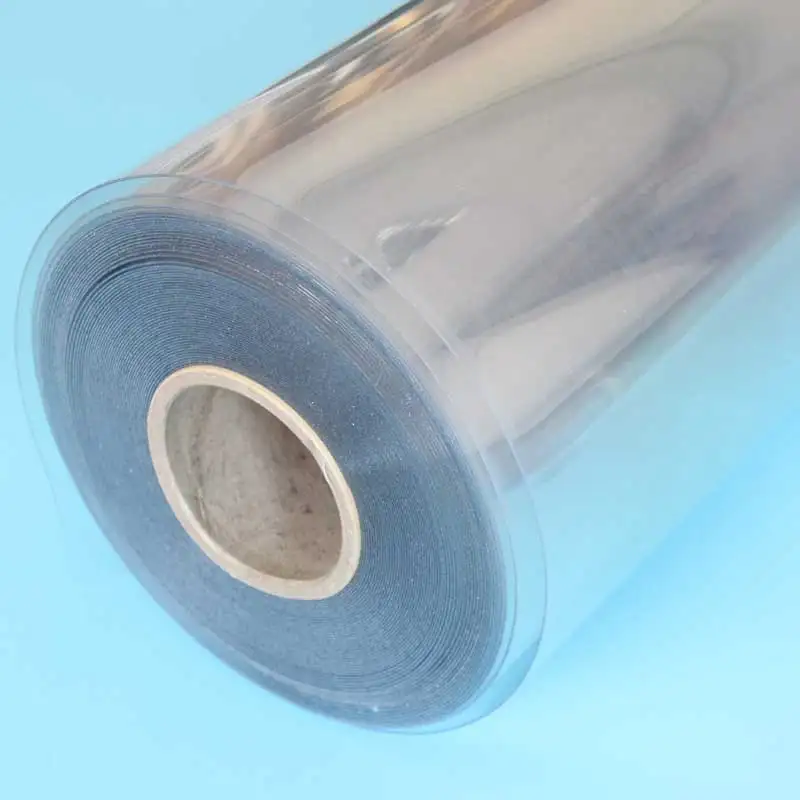

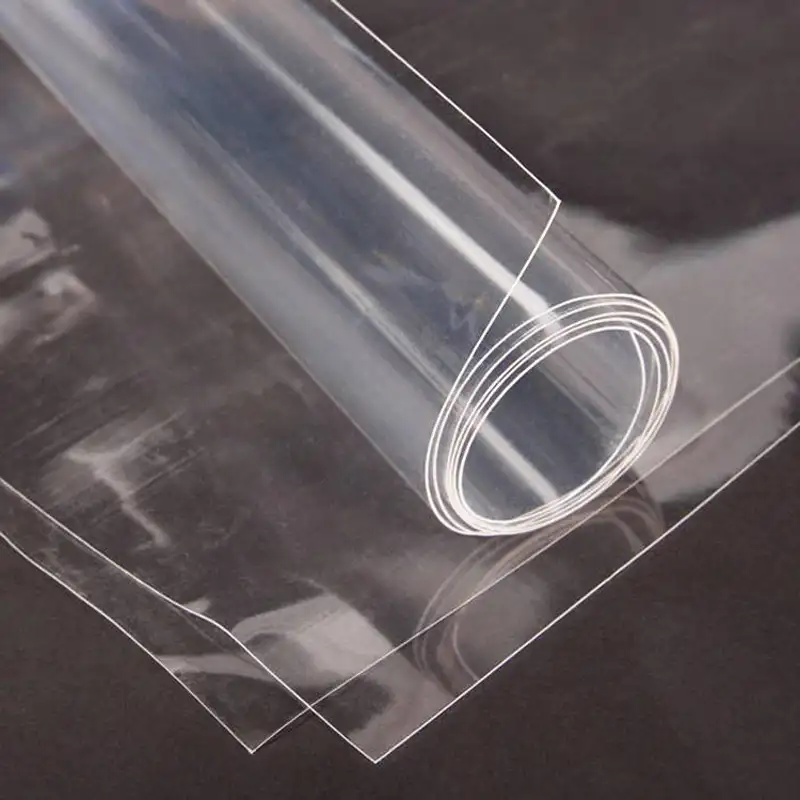

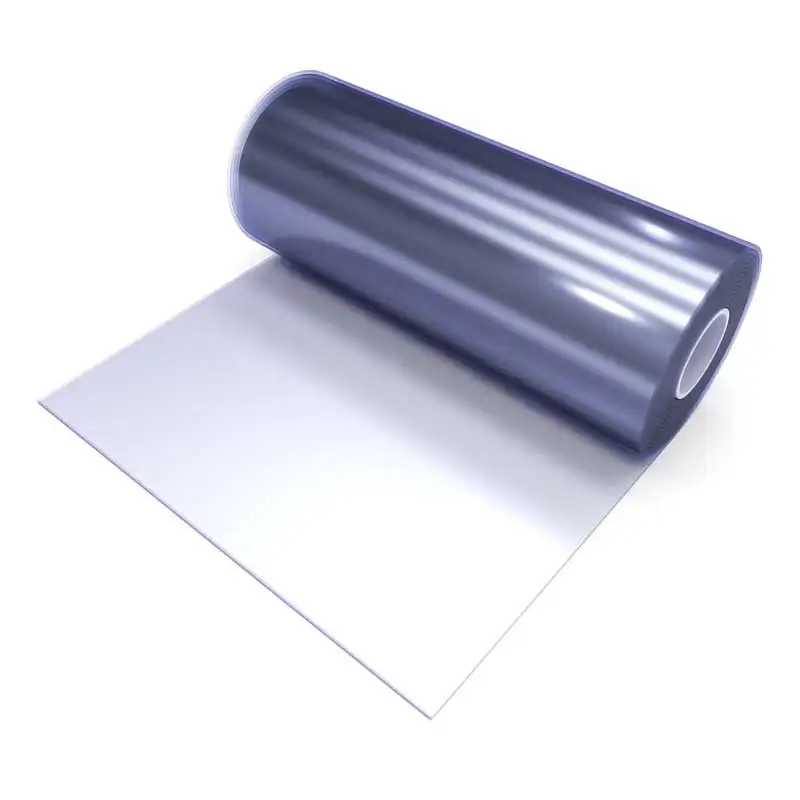

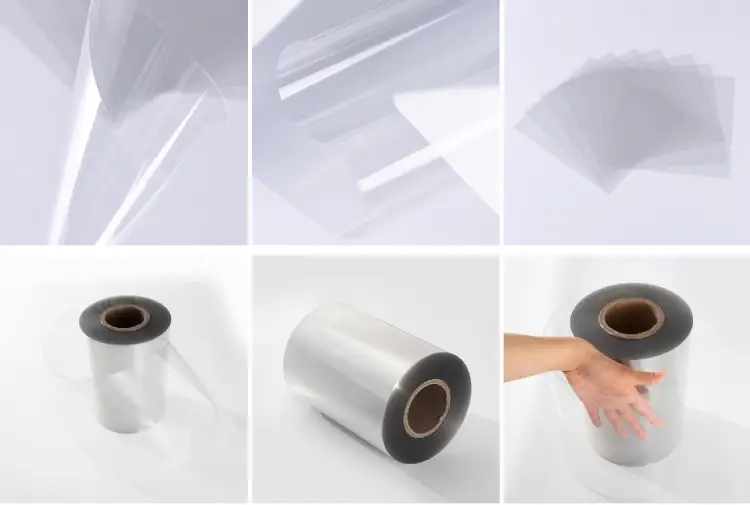

PET plastic sheet rolls are thermoplastic materials produced by extruding polyethylene terephthalate resin into thin, uniform sheets. These sheets are then rolled for easy transportation, storage, and processing. Manufacturers can thermoform, vacuum form, or cut PET sheets into customized shapes for various packaging applications. Compared to traditional plastics like PVC or PS, PET provides superior transparency, strength, and recyclability—key factors driving its popularity in sustainable packaging.

The Shift Toward Sustainable Packaging

One of the most significant reasons PET plastic sheet rolls are transforming the industry is their environmental advantage. PET is 100% recyclable and can be reprocessed multiple times without losing its clarity or strength. This aligns with the growing global focus on circular economy principles, where materials are reused and repurposed instead of discarded.

Packaging companies and brand owners increasingly choose PET over non-recyclable alternatives to reduce carbon emissions and meet government regulations on plastic waste reduction. As a result, PET sheet rolls have become the preferred choice for companies striving to balance functionality and sustainability.

Exceptional Performance and Versatility

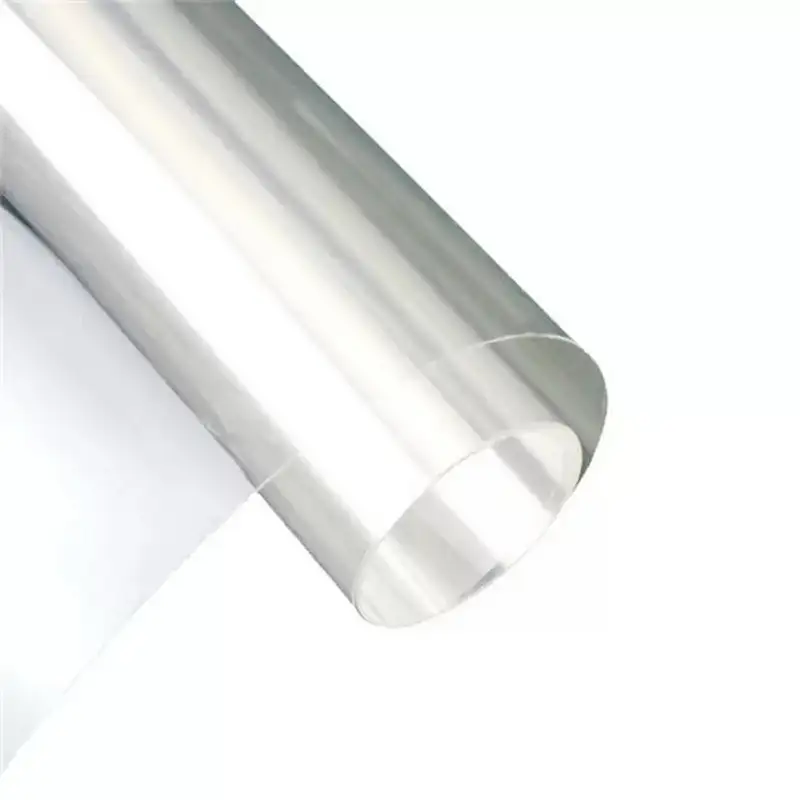

Beyond sustainability, PET plastic sheet rolls deliver exceptional physical and mechanical properties. They are lightweight yet strong, offering excellent impact resistance that protects products during shipping and handling. Their superior clarity enhances product visibility, making packaging more attractive on retail shelves.

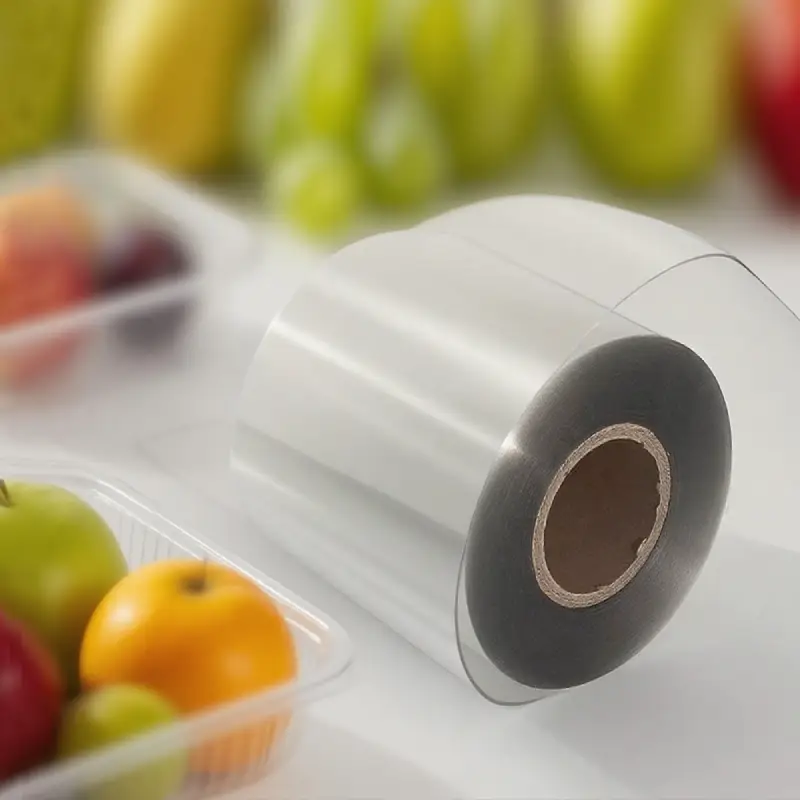

PET plastic sheets can withstand a wide range of temperatures, making them suitable for both hot and cold food packaging. Their excellent gas and moisture barrier properties also help extend the shelf life of perishable products. Whether used in food trays, blister packs, or clamshell containers, PET plastic sheet rolls provide reliable protection without compromising design flexibility.

Wide Range of Applications

The adaptability of PET plastic sheet rolls makes them suitable for diverse industries:

Food Packaging: PET plastic sheets are commonly used in disposable food trays, bakery containers, and fruit boxes. Their non-toxic nature and FDA compliance make them ideal for direct food contact.

Pharmaceutical and Cosmetic Packaging: PET offers excellent clarity and hygiene, helping brands showcase products while maintaining safety.

Electronics Packaging: Anti-static PET sheet rolls are widely used to protect sensitive components during shipping and storage.

Blister and Clamshell Packaging: The high formability of PET allows precise shaping for custom packaging solutions.

This broad application range ensures PET remains a dominant material in global packaging solutions.

Technological Advancements in PET Manufacturing

Modern PET sheet production has evolved with the adoption of advanced extrusion technologies. Manufacturers now use automated extrusion lines that ensure consistent thickness, smooth surfaces, and superior clarity. Additives can also be integrated to enhance properties—such as anti-fog, UV resistance, or anti-static—depending on customer requirements.

Leading factories maintain strict quality control systems, ensuring every roll meets international standards like ISO9001 and ISO22000. Such technological progress not only improves performance but also lowers production costs, allowing manufacturers to offer cost-effective yet high-quality packaging materials.

Meeting Global Market Demands

The demand for PET plastic sheet rolls continues to rise globally. According to market analyses, the packaging sector is expected to grow steadily due to increasing consumption of packaged foods, e-commerce expansion, and sustainability initiatives. PET’s recyclability, clarity, and efficiency perfectly align with these trends, making it a strategic material for long-term growth.

Packaging companies are also leveraging PET’s properties to design lightweight, transport-efficient packaging, which reduces overall logistics costs and carbon footprints. This makes PET not only a sustainable option but also a smart business choice.

The Role of Reliable Manufacturers

Behind the success of PET plastic sheet rolls are manufacturers committed to quality, innovation, and customer satisfaction. Reliable suppliers invest in advanced production equipment, strict testing systems, and continuous product development to meet diverse client needs. By offering customized thickness, color, width, and surface finishes, these manufacturers help businesses create packaging that stands out while meeting functional requirements.

Factories like DESU exemplify this commitment, producing a wide range of PET plastic sheet rolls for thermoforming, blister, and vacuum packaging. Our dedication to quality and sustainability ensures customers receive consistent, high-performance materials suitable for both domestic and international markets.

Why Choose DESU PET Plastic Sheet Rolls?

DESU is a factory-qualified PET plastic sheet roll manufacturer based in China, specializing in producing high-quality materials for food, electronics, and industrial packaging. With years of experience and advanced extrusion technology, DESU provides reliable, customizable solutions to meet global customer demands.

Reasons to Choose DESU:

Factory-Direct Quality: DESU operates multiple production facilities equipped with modern extrusion lines to ensure stable supply and consistent quality.

Customizable Specifications: Thickness from 0.2mm to 2.0mm, width up to 1220mm, and color options including transparent, white, black, and custom tones.

Sustainability Commitment: All PET sheet rolls are 100% recyclable and produced under eco-friendly manufacturing processes.

Fast Delivery and Export Support: DESU’s efficient logistics and experienced export team ensure on-time shipments and smooth international trade.

Comprehensive Applications: Whether for food packaging, electronic component trays, or blister packs, DESU’s PET sheets are designed to perform reliably in every use case.

By choosing DESU PET Plastic Sheet Rolls, customers gain access to durable, visually appealing, and environmentally responsible packaging materials backed by expert support and global service.

The Future of Packaging with PET

As the world continues to prioritize environmental protection and efficient production, the role of PET plastic sheet rolls will only expand. With ongoing innovation in material science and recycling technologies, PET will continue to replace less sustainable plastics, pushing the packaging industry toward a greener and more efficient future.

Companies adopting PET sheet solutions not only demonstrate environmental responsibility but also gain a competitive edge by meeting modern consumer expectations for clean, transparent, and sustainable packaging.

Conclusion

PET plastic sheet rolls are reshaping the global packaging industry through their combination of sustainability, versatility, and performance. From food to electronics packaging, they offer unmatched benefits in clarity, durability, and eco-friendliness. As more manufacturers and brands embrace environmentally responsible materials, PET plastic sheet rolls—especially those from DESU—stand out as the clear choice for packaging innovation and the future of sustainable manufacturing.

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Main Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Latest Products

PET-SHEET.COM

PET-SHEET.COM