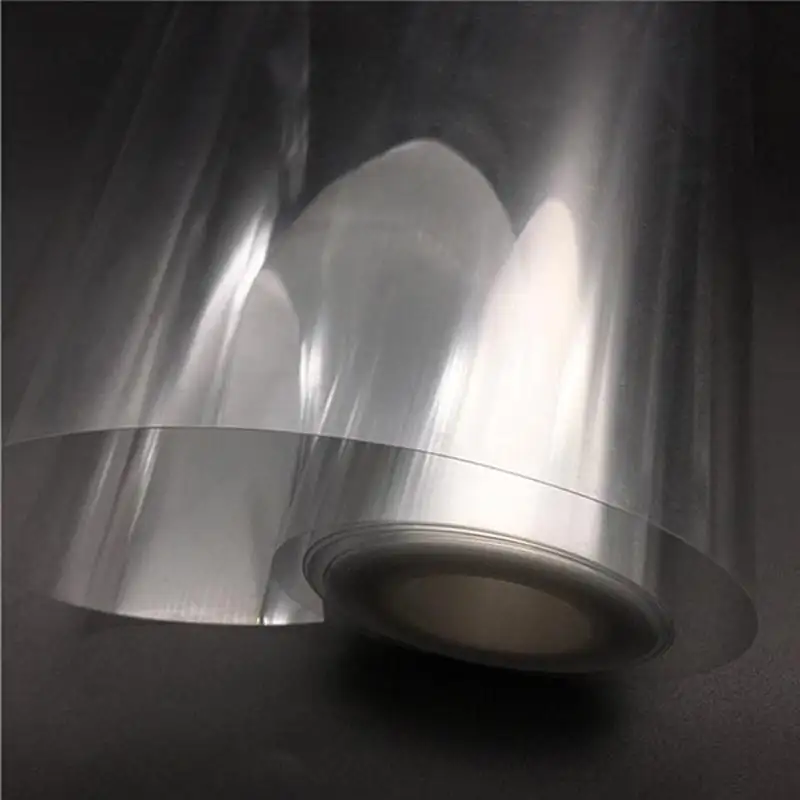

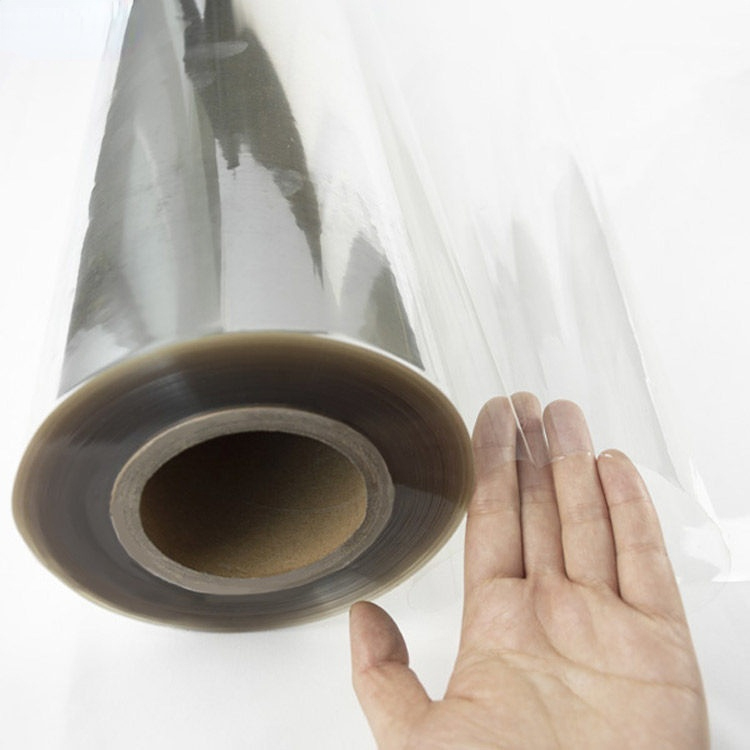

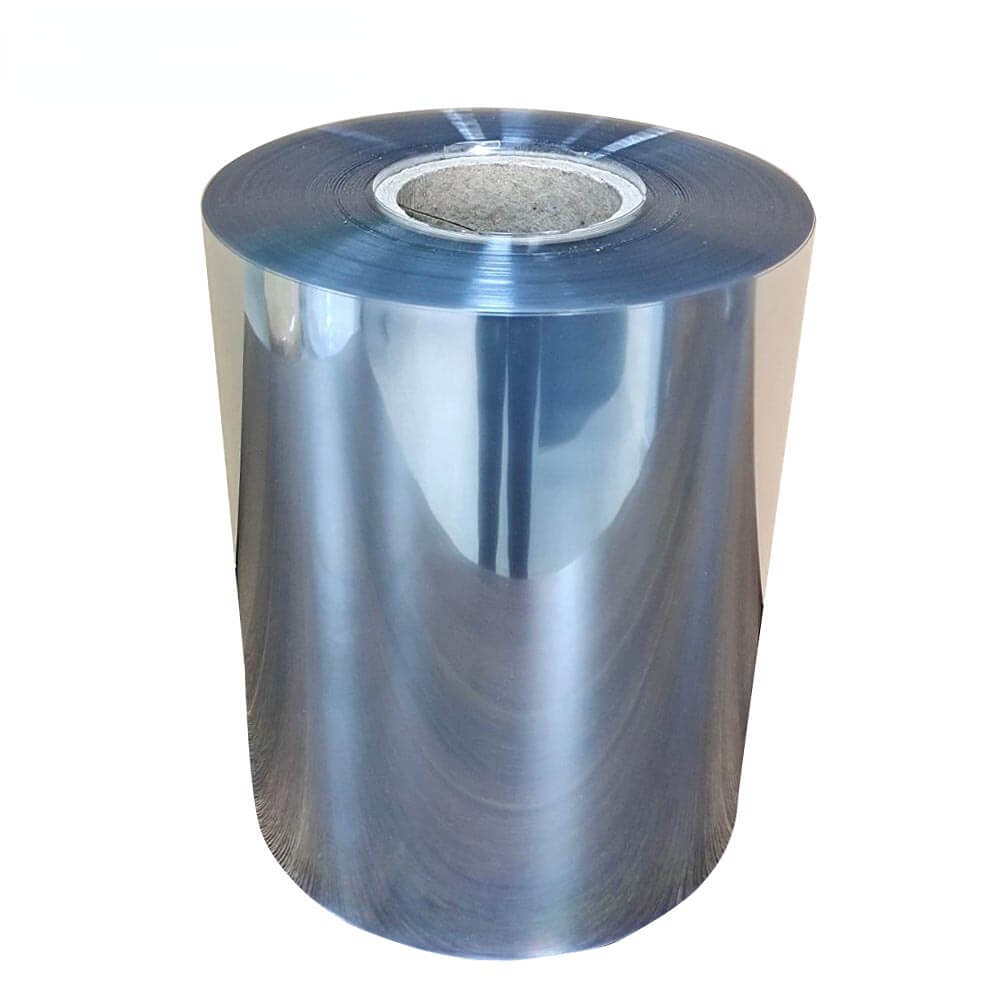

1mm Conductive Transparent PET Plastic Sheet Rolls

PET-SHEET.COM

PET-SHEET.COM

- Production Limits:

- Thickness Range: 0.18mm-1.8mm

- Width Range: 350mm-1300mm

- Color Range: Clear/Transparent/Black/White/Customize Color

- MOQ: 5 tons (free sample accepted )

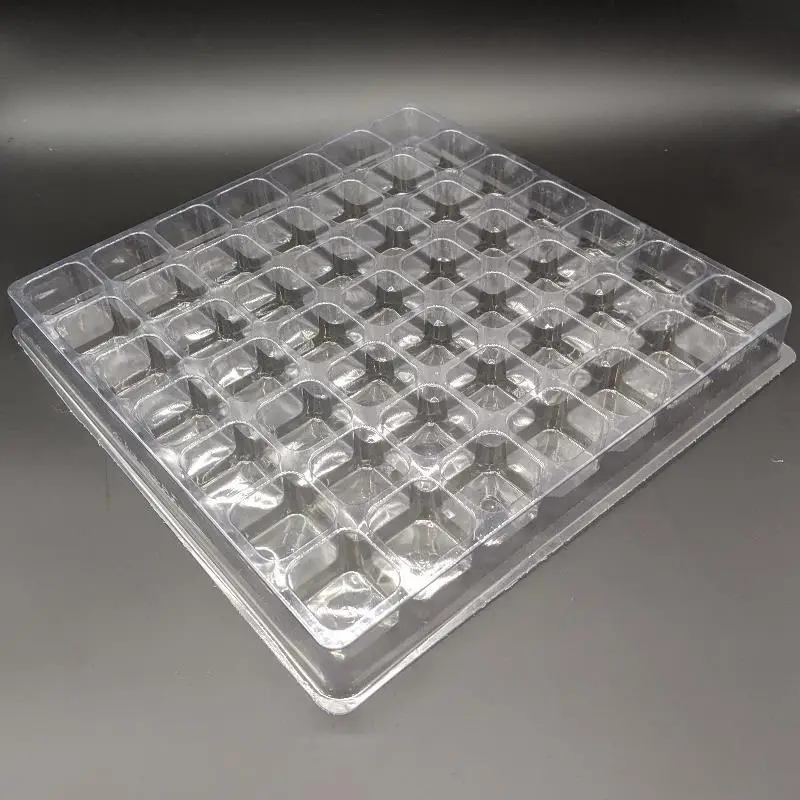

- Applications: Thermoforming Tray / Electronic Tray / Fresh Food Tray / Blister Packaging

Are you looking for this? Thermoforming PET Sheet Roll. pet-sheet.com is A factory focus on Manufacturer and Export rigid Thermoforming PET Sheet Roll for thermoforming or blister packaging. As to "1mm Conductive Transparent PET Plastic Sheet Rolls", if you leave us your requirement like PET plastic thickness, width and application, Our professional sales will quote your the best competitive price.

| PROPERTIES | METHOD | UNIT | SPEC |

|---|---|---|---|

| Coefficient of Kinetic Friction | GB/T 10006 | --- | ≦0.350 |

| Specific gravity | ASTM D-792 | g/cm3 | 1.345 |

| Meliting Temperature | ASTM D-3418 | ℃ | 250±5 |

| Glass Transition Temperature | ASTM D-3418 | ℃ | 65~75 |

| Haze | ASTM D-1003 | % | ≦3.0 |

| Tensile Elongation@Break | ASTM D-638 | % | ≧450 |

| Tensile Strength@Yield | ASTM D-638 | Kg/cm2 | ≧550 |

Product Introduction of 1mm Conductive Transparent PET Plastic Sheet Rolls

Our 1mm Conductive Transparent PET Plastic Sheet Rolls combine the durability and clarity of polyethylene terephthalate (PET) with surface conductivity, making them ideal for high-performance electronic packaging and EMI shielding applications.

Key Features

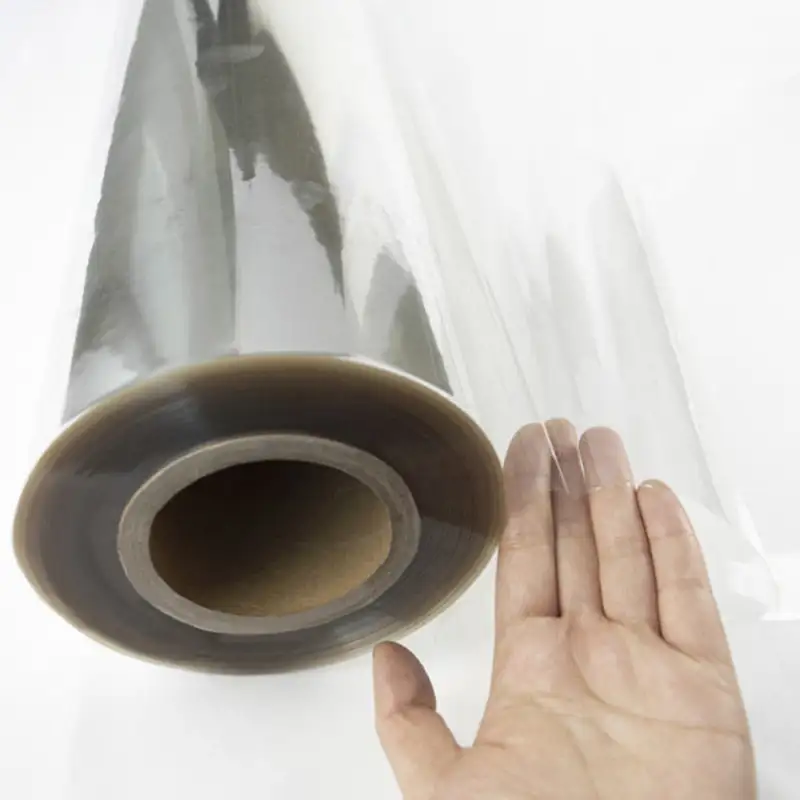

Thickness: 1mm

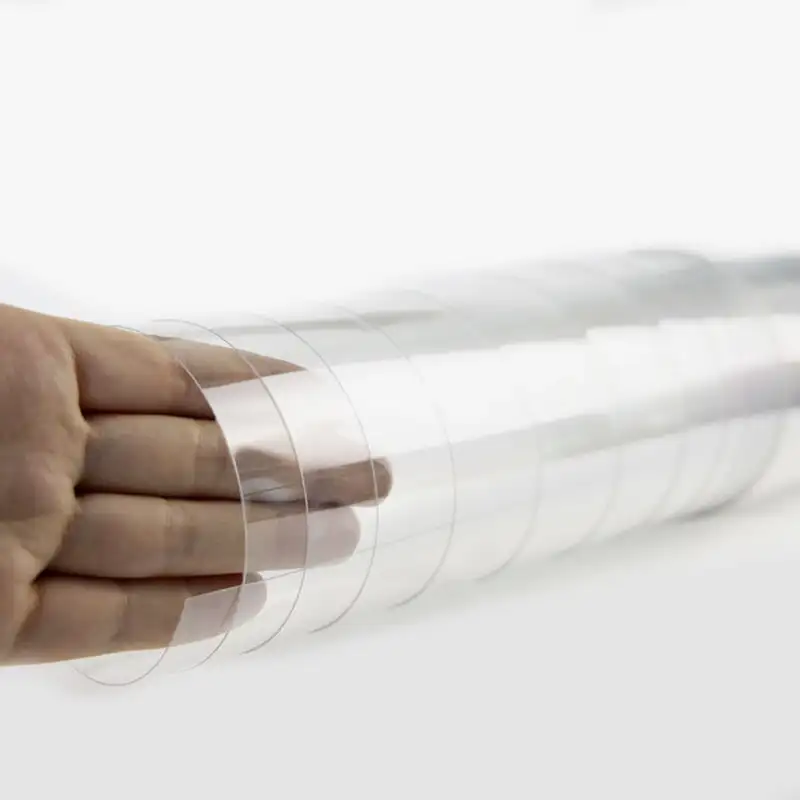

Transparency: High optical clarity

Conductivity: Surface resistance ≤ 10⁶ Ω/sq

Material: Modified PET with conductive coating

Surface Finish: Smooth, anti-static, dust-resistant

Width & Roll Length: Customizable to meet your specifications

Performance Advantages of 1mm Conductive Transparent PET Plastic Sheet Rolls

1. Excellent Surface Conductivity

Effective in dissipating static electricity, suitable for ESD-sensitive components.

2. Superior Transparency

Maintains visibility for display windows, screen covers, and sensor applications.

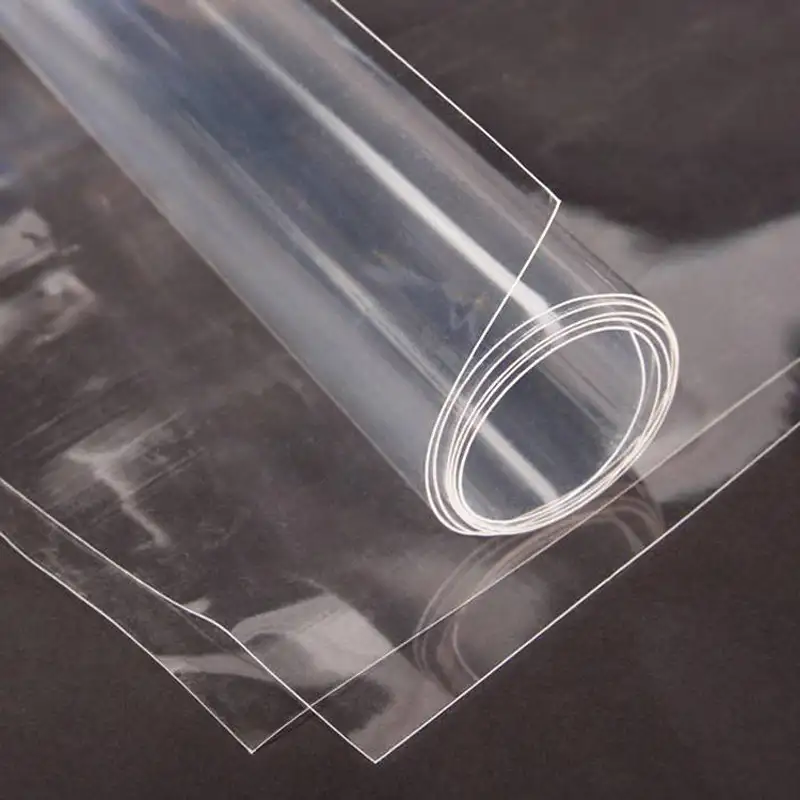

3. Thermoformable

Easy to mold, punch, and cut for blister packaging, tray manufacturing, and electronic enclosures.

4. Chemical Resistance

Withstands exposure to oils, alcohols, and mild acids.

5. Eco-Friendly

Recyclable material with low environmental impact.

Application of 1mm Conductive Transparent PET Plastic Sheet Rolls

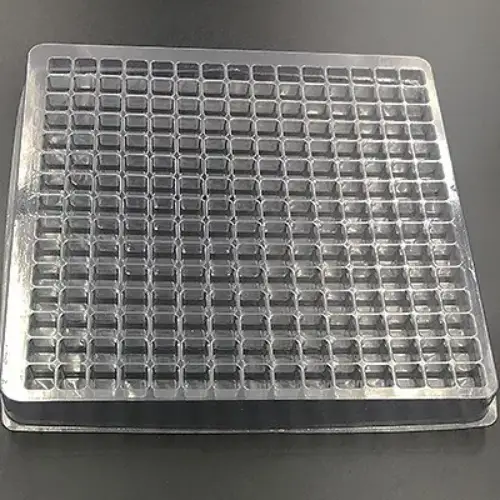

1. Semiconductor Chip Packaging

Used for packaging IC chips, wafers, diodes, transistors, etc., to prevent electrostatic damage.

2. Electronic Components Trays

Ideal for anti-static trays or blister trays used with capacitors, resistors, connectors, relays, and other electronic parts.

3. Mobile Phone and Tablet Component Packaging

Used for screen modules, camera modules, and batteries during production and shipping.

4. LCD/LED Display Screen Protection Packaging

Transparent conductive layers help prevent static buildup while providing clear visibility.

5. Hard Drive, Motherboard & PCB Packaging

Protects sensitive components from static discharge during transportation or assembly.

6. Optoelectronic Devices & Sensor Packaging

Perfect for static-sensitive parts such as IR modules, laser devices, and image sensors.

7. Medical Electronic Device Packaging

Suitable for dust-free and anti-static packaging of high-precision medical electronic components.

Parameter of 1mm Conductive Transparent PET Plastic Sheet Rolls

| Product name | PET Sheet, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

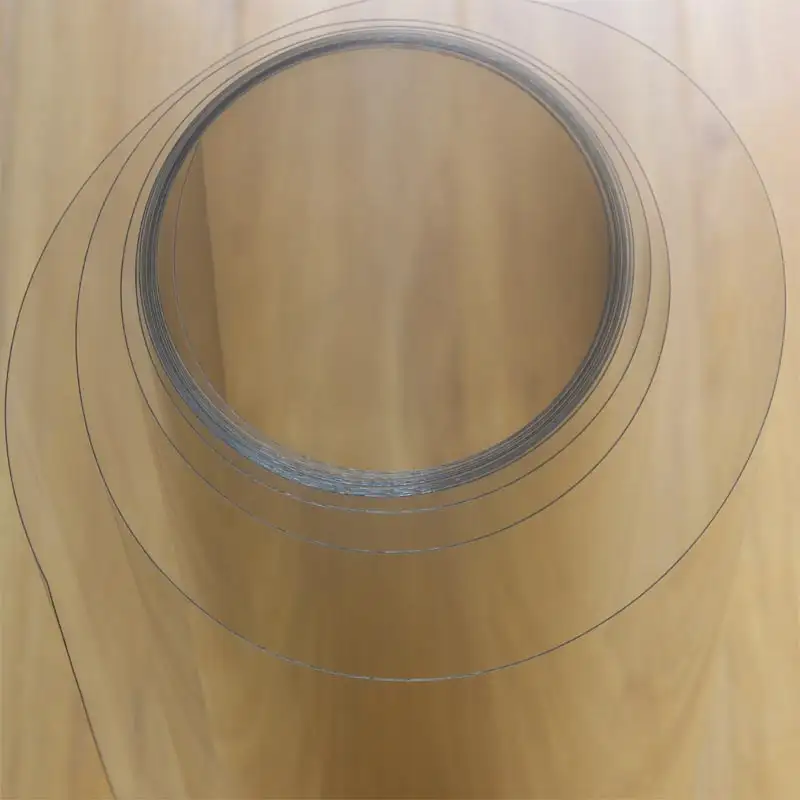

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

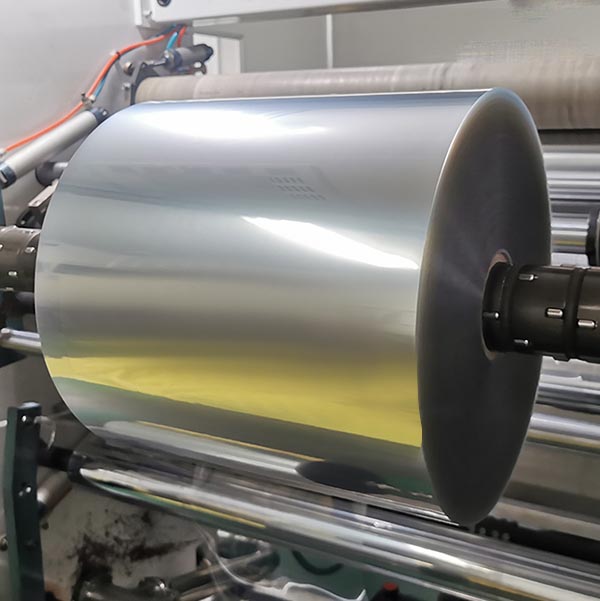

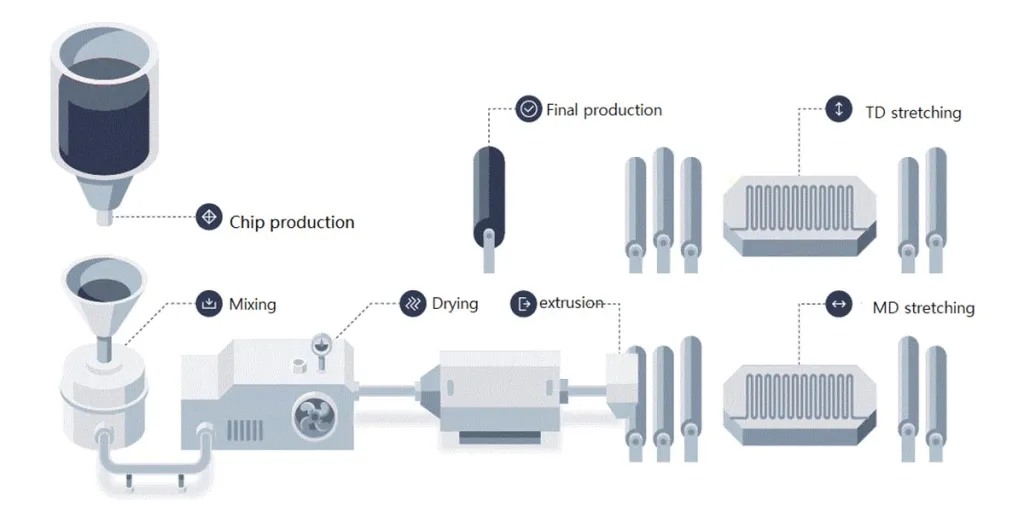

Production Process of 1mm Conductive Transparent PET Plastic Sheet Rolls

1. Raw Material Preparation

- Selection of high-viscosity PET resin (virgin or recycled grade depending on requirements)

- Addition of conductive additives or preparation for surface coating (e.g., ITO, conductive carbon, or polymer layers)

2. Drying

- PET raw material is dried in a dehumidifying dryer at 160–180°C to remove moisture and prevent hydrolysis during extrusion.

3. Extrusion & Sheet Forming

- The dried PET resin is melted in a twin-screw extruder.

- Melt passes through a T-die to form a flat sheet with controlled thickness (1mm).

- Optionally co-extruded with other layers if multilayer structure is required.

4. Quenching & Cooling

- The molten sheet is cooled rapidly on a chill roll to preserve transparency and control crystallization.

5. Conductive Coating (if applicable)

- A thin, transparent conductive layer (e.g., ITO or conductive polymer) is applied via:

- Roll-to-roll vacuum sputtering (for ITO)

- Spray coating or dip coating

- Gravure or slot-die coating

- Followed by drying and curing (UV or thermal).

6. Surface Treatment

- Anti-static treatment or hard coating for scratch resistance (optional).

- Corona treatment or primer coating if adhesion improvement is needed.

7. Thickness & Surface Quality Inspection

- Online thickness gauge (laser or beta-ray) ensures uniformity.

- Visual inspection for optical clarity, bubbles, streaks, or contamination.

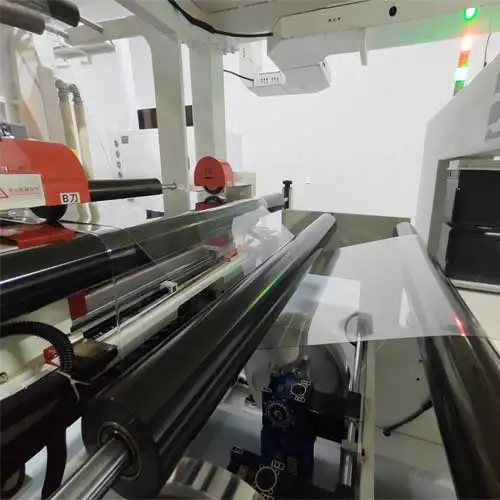

8. Slitting & Rewinding

- The wide sheet is slit into required roll widths and rewound into customer-specified roll lengths.

9. Packaging

- Rolls are packed in anti-static PE film and placed in ESD-safe cartons or pallets.

10. Quality Control

- Final inspection includes surface resistivity testing, haze & light transmittance measurement, and mechanical property checks.

Why Choose pet-sheet.com

Co-extrusion Production

Co-extrusion Production

Quality Inspection

Quality Inspection

Safe Packing

Safe Packing

On Time Delivery

On Time Delivery

CONTACT PET-SHEET.COM

Our professional sales staff and technicians will determine the final characteristics of the product and material solution for the customer specific application and will provide the customer with a quote and a detailed time schedule, Please fill the form to contact our professional sales team.- Category

- APET Sheet Roll

- ESD Antistatic PET Sheet Roll

- GAG Sheet Roll

- PETG Sheet Roll

- RPET Sheet Roll

- Thermoforming PET Sheet Roll

- Similar Products

- Food Grade PET Plastic Rolls for Thermoforming Packaging

- Conductive PET plastic rolls

- PET Thermoforming Plastic Rolls

- Blister Packaging PET Plastic Rolls

- PET Plastic Rolls for Bread Trays

- PET sheet roll for Toy packaging

- PET Plastic Sheet Rolls for Packaging Solutions

- 0.8mm Polyethylene Terephthalate Plastic Sheet Rolls

- 0.6mm Polyethylene Terephthalate Plastic Sheet Rolls

- Premium PET Sheet Rolls for Food Tray

- 1.7mm PET Plastic Sheet Rolls

- PET plastic rolls for Toothbrush packaging

- 2.0mm PET Plastic Rolls

- PET Plastic Sheet Rolls for Coffee Cups

- 1.8mm Thermoforming PET Plastic Sheet Rolls

- 1.6mm Thermoforming PET Plastic Rolls

- 1.4mm PET Plastic Sheet Rolls

- 1.3 mm PET plastic rolls

- 1.0mm PET plastic sheet rolls

- 0.9mm PET Plastic Rolls

PET-SHEET.COM

PET-SHEET.COM